Steel forming method and forming component

A technology for forming components and steel materials, which is applied to vehicle parts, transportation and packaging, and can solve problems such as high energy consumption, high cost, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

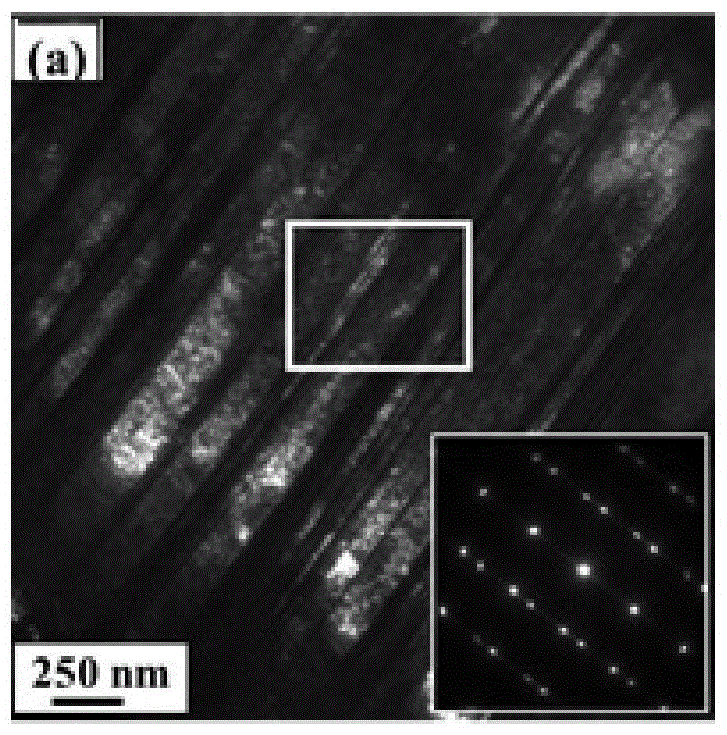

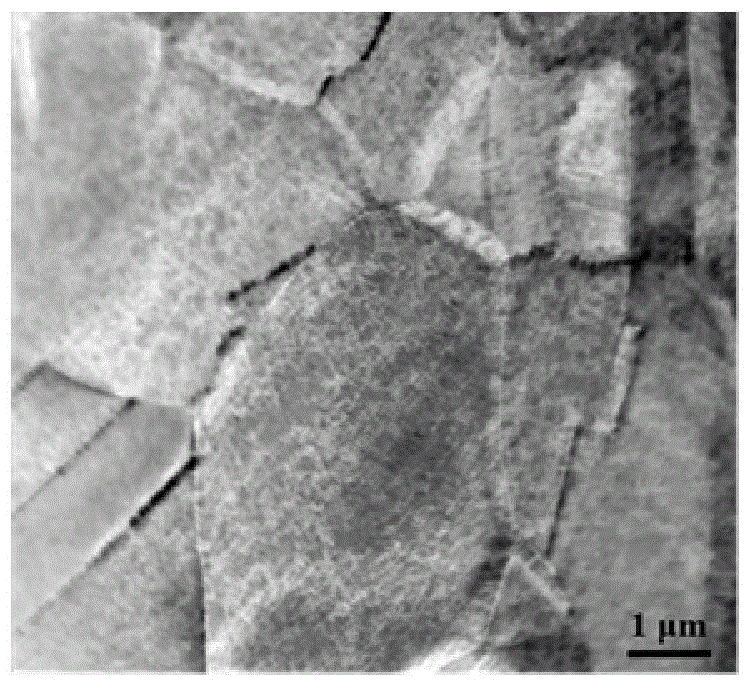

[0021] The inventors have found through research that deformation twins can be formed in the deformation process of TWIP steels, and some TWIP steels also have austenite transformation into martensite, and the formation of twins or the formation of martensite provides a guarantee for delayed cracking. Convenience channels, so TWIP steel has such a large risk of delayed cracking. Therefore, reducing the number or even orders of magnitude of twins in TWIP steel during forming and simultaneously inhibiting the formation of martensite provides a way to solve the problem of delayed cracking.

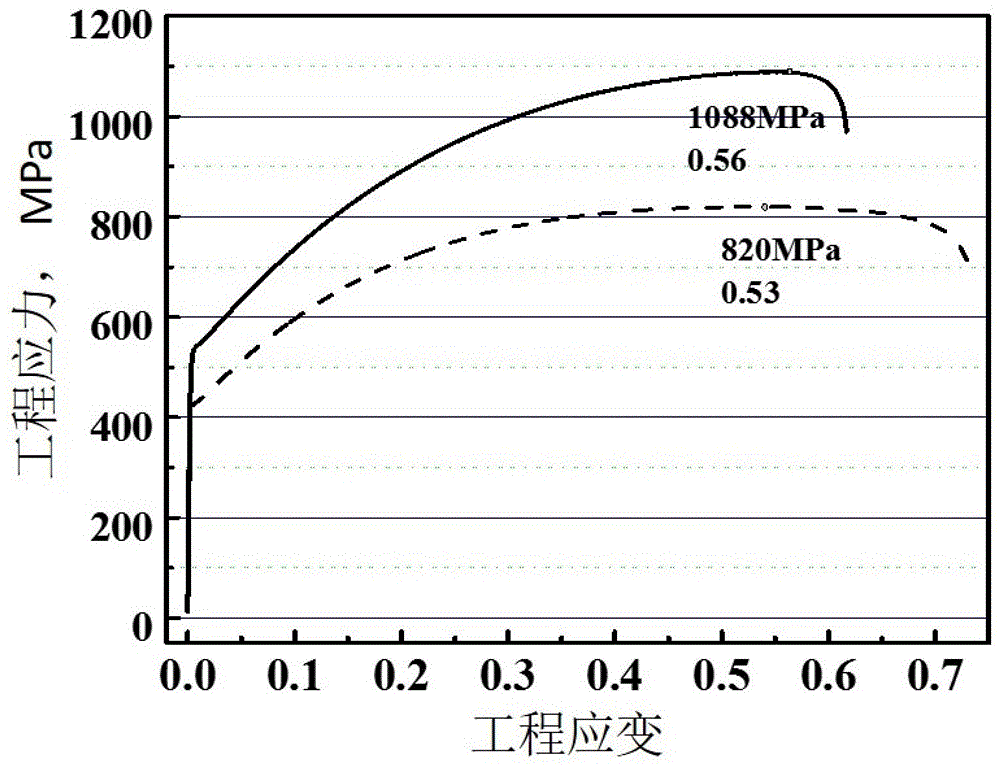

[0022] The performance and plastic deformation mechanism of steel materials based on austenite such as TWIP steel mainly depend on their stacking fault energy (SFE: Stacking Fault Energy). At room temperature, the stacking fault energy of high-manganese TWIP steel is low, and twins will be formed during plastic deformation. The stacking fault energy is closely related to temperature. At a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com