Method of preparing High W content Ni-W alloy for high temp superconduct

A high-temperature superconducting and high-temperature technology, which is applied in the field of high-temperature superconducting coating tough baseband and superconducting thin film preparation, can solve the problems of low mechanical strength, affecting the application of YBCO coating conductors or AC applications, and unfavorable superconducting long strip materials. , to achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1. Adopting Ni powder and W powder as raw materials, the purity is 99.9% by weight, the Ni powder particle size is 4~6 microns, the W powder particle size is 3~4 microns, and W accounts for 7.01% by atomic percentage in the alloy. After mixing evenly, put it into a mold for SPS sintering. The sintering temperature is 800° C., and the sintering holding time is 10 minutes. The sintering pressure is 80MPa. A Ni-7.01%W block with a density of 97.2% was obtained.

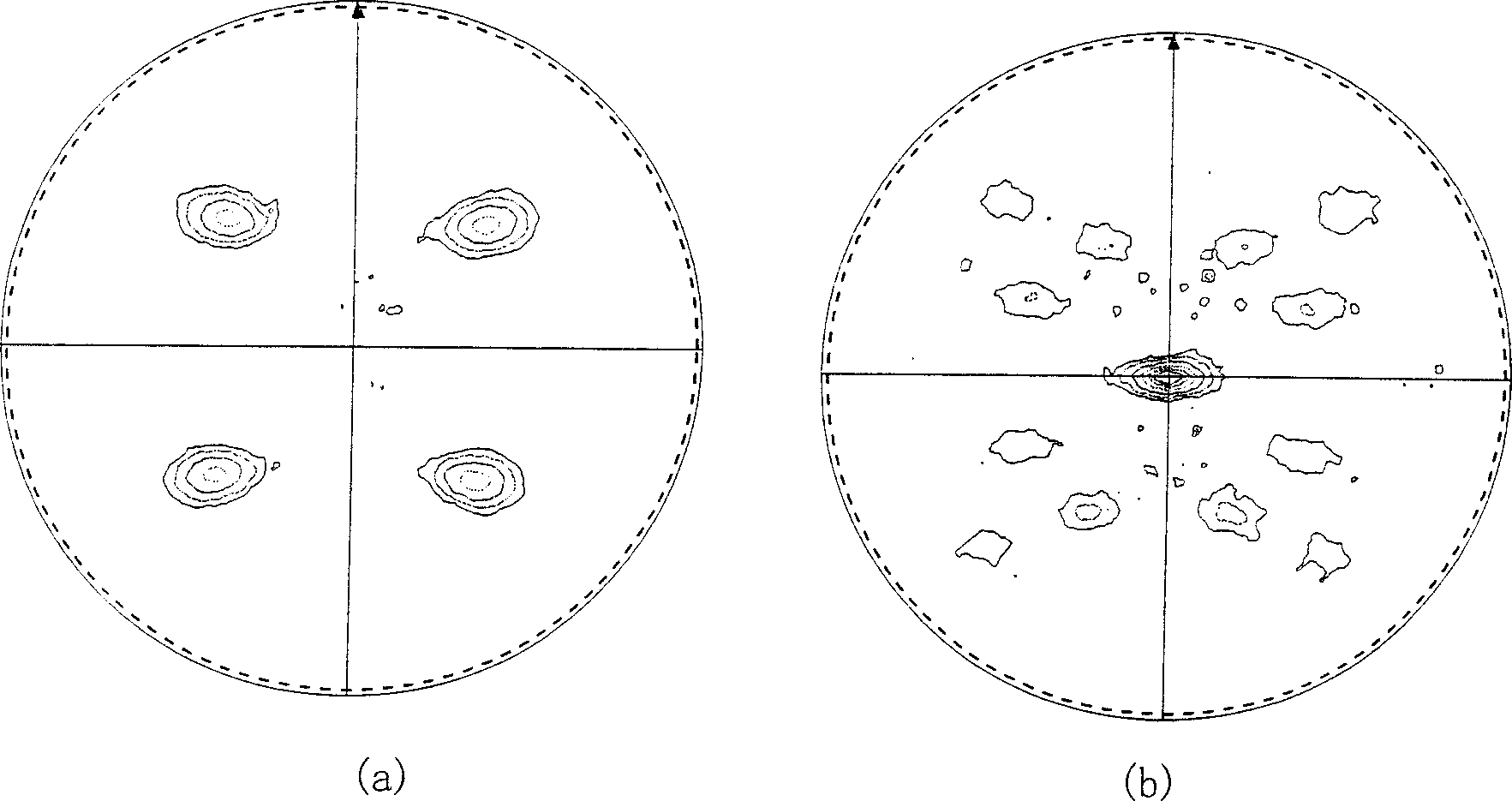

[0020] Carry out cold rolling and recrystallization annealing on the Ni-7.01% W block, the deformation of the cold rolling pass is 7-8%, and the total deformation is 97%. During the cold rolling process, the deformation reaches 80%, and an intermediate annealing is carried out , the annealing temperature is 800°C, and the annealing time is 0.5 hours. Then use H 2 The volume percentage is 4% Ar+H 2 Recrystallization annealing was carried out in a mixed atmosphere, the annealing temperature was 1000° C....

example 2

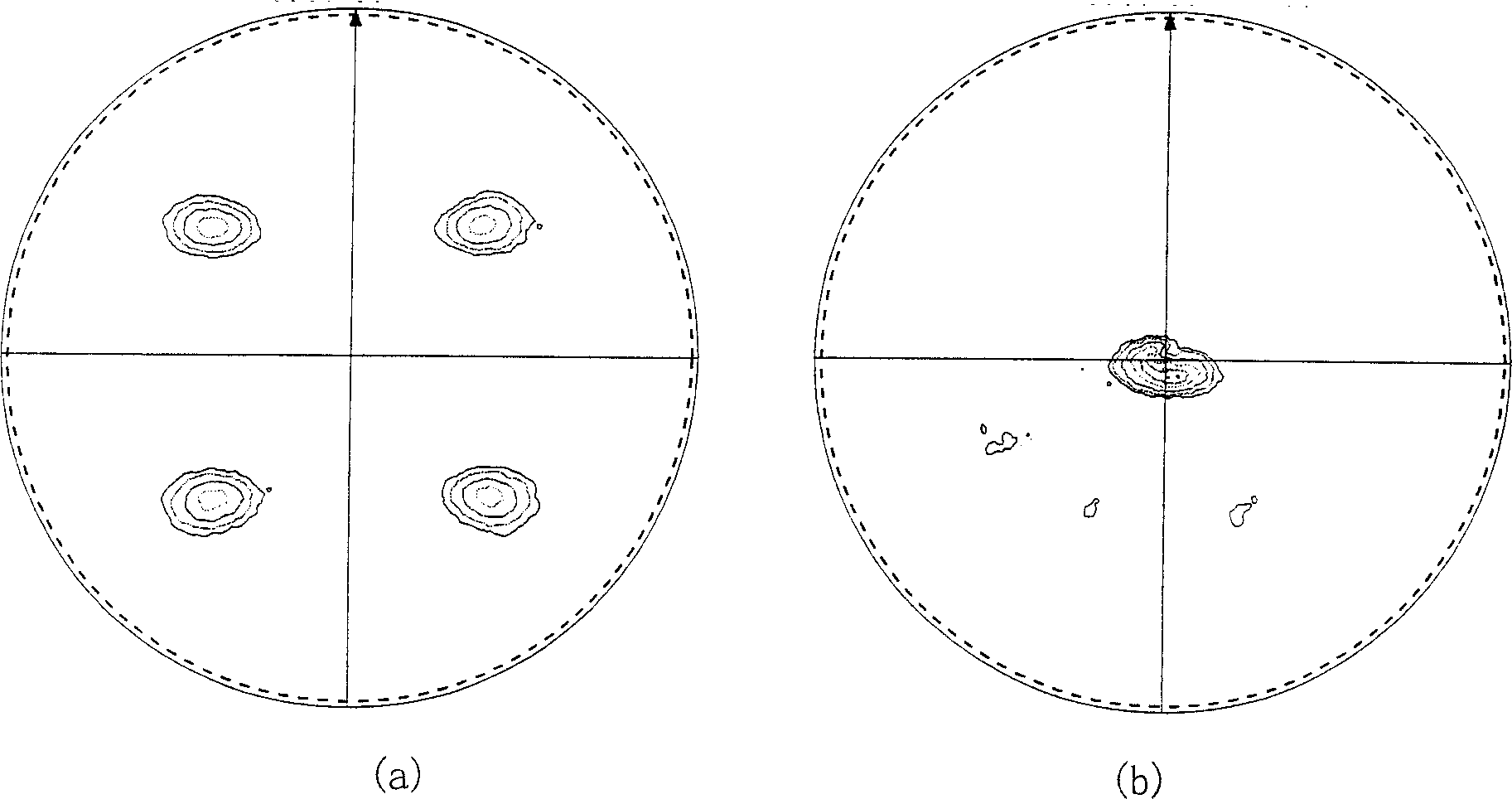

[0021] Example 2. Adopting the Ni-7.01% W block prepared in Example 1, carrying out cold rolling and recrystallization annealing, the pass deformation of cold rolling is 5~6%, and the total deformation is 95%. , every time the amount of deformation reaches 60%, an intermediate annealing is performed, and a total of 2 intermediate annealings are performed, the annealing temperature is 300°C, and the annealing time is 6 hours. Then use H 2 The volume percentage is 4% Ar+H 2 Recrystallization annealing is carried out in a mixed atmosphere, the annealing temperature is 1100° C., and the annealing time is 2 hours. Thin ribbons with a strong, single-oriented {100} texture were obtained, figure 2 are its (111) and (200) pole figures. A very good cubic texture Ni-7.01%W baseband material is obtained, which can be used for the preparation of subsequent YBCO-coated superconducting materials.

example 3

[0022] Example 3. adopt Ni powder and W powder as raw materials, the purity is 99.9% by weight, the particle size of Ni powder is 4~6 microns, the particle size of W powder is 3~4 microns, and W accounts for 8.5% by atom percentage in the alloy. After mixing evenly, put it into a mold for SPS sintering. The sintering temperature is 1300°C, and no sintering heat preservation is carried out. The sintering pressure is 30MPa. A Ni-9.5%W block with a density of 97.5% was obtained.

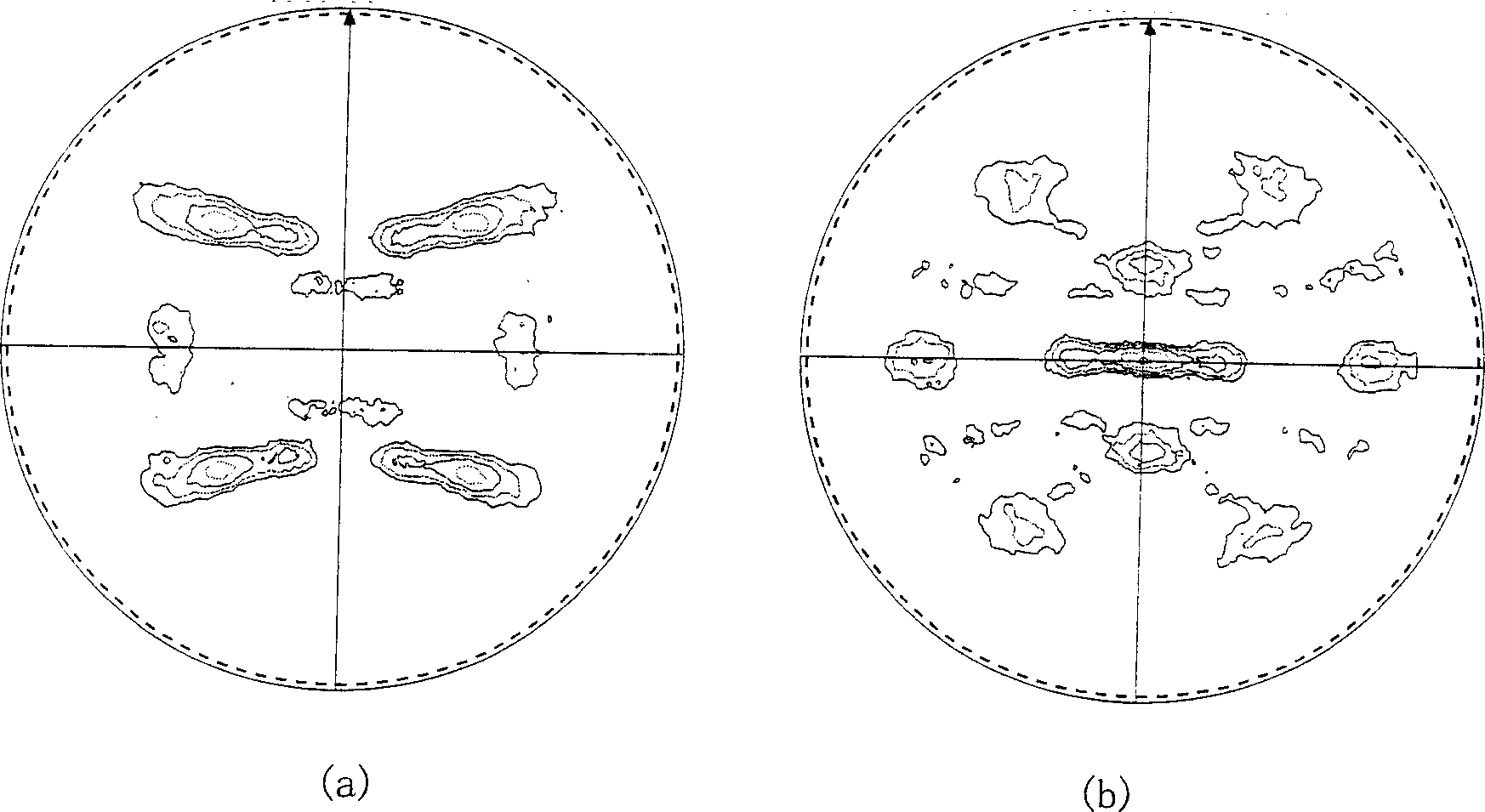

[0023] Cold rolling and recrystallization annealing are carried out on the Ni-8.5% W block at room temperature. The deformation of the cold rolling pass is 3-4%, and the total deformation is 98%. During the cold rolling process, the deformation reaches 50%. One intermediate annealing was carried out, a total of four intermediate annealings were carried out, the annealing temperature was 500°C, and the annealing time was 3 hours. Then use H 2 The volume percentage is 7% Ar+H 2 Recrystallization anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com