High strength and ductility alloy steel and heat treatment technology thereof

A high-strength plastic product and alloy steel technology, applied in the field of high-alloy steel, can solve problems such as unclear relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] 1. Chemical composition and heat treatment process of high strength and high elongation TWIP steel

[0027] 1.1 Chemical composition

[0028] C: 0.03~0.05%, Mn:: 30±0.5%, Al: 3±0.5%, Si 3±0.5%, and the rest is Fe.

[0029] 1.2 Heat treatment process

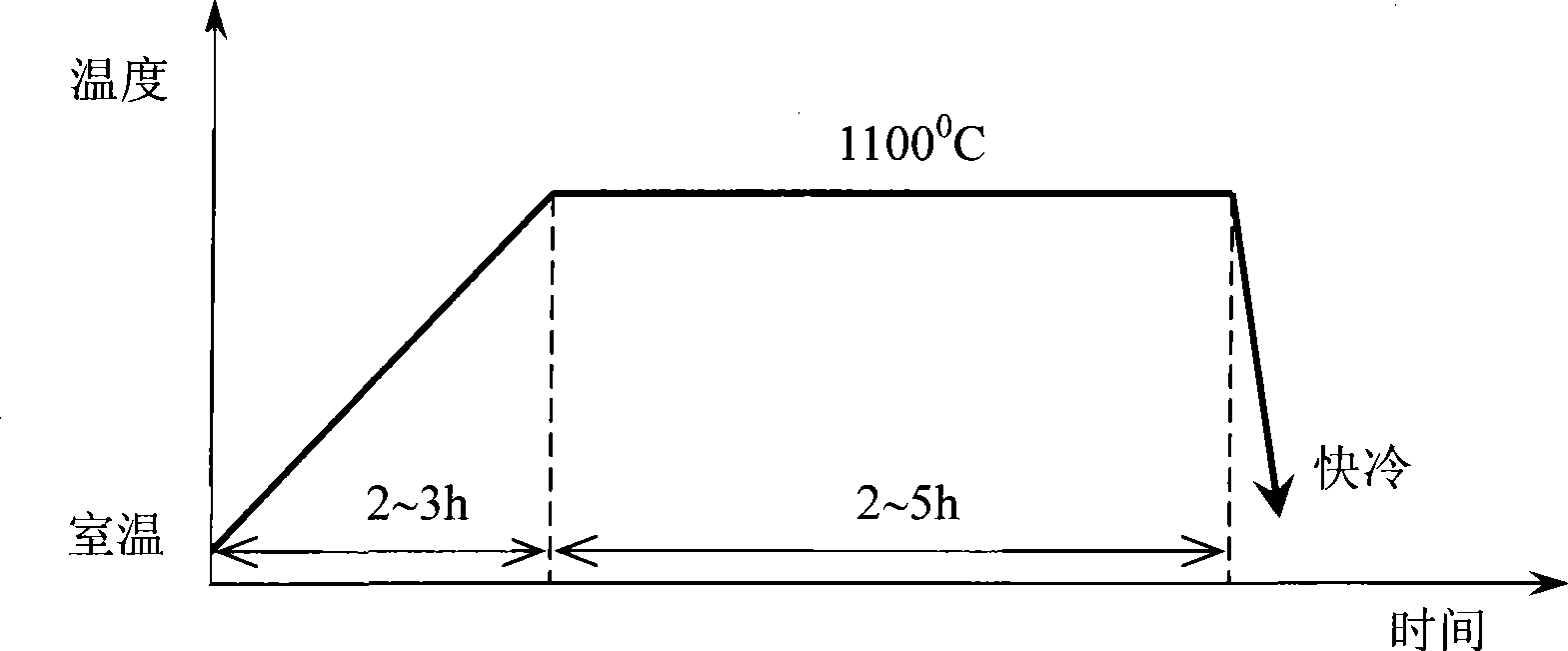

[0030] Process system such as figure 1 As shown, the specific requirements are as follows:

[0031] (1) Place the workpiece in a resistance heating furnace (with or without atmosphere protection), and an appropriate gap should be left between the workpieces;

[0032] (2) Electric heating, heating rate 6 ~ 9 ℃ / minute;

[0033] (3) Start heat preservation when the temperature rises to 1100°C, at this time, the temperature jump is ≤±5°C, and the heat preservation time is 2 to 5 hours (depending on the size of the workpiece);

[0034] (4) After the heat preservation is over, take the workpiece out of the resistance heating furnace, quickly put it into the water pool (water temperature ≤ 30°C) and swing it;

[0035] (5)...

example 2

[0039] 2. Chemical composition and heat treatment process of high elongation and high strength TWIP steel

[0040] 2.1 Chemical composition

[0041] C: 0.001~0.003%, Mn:: 25±0.5%, Al: 3±0.5%, Si 3±0.5%, and the rest is Fe.

[0042] 2.2 Heat treatment process

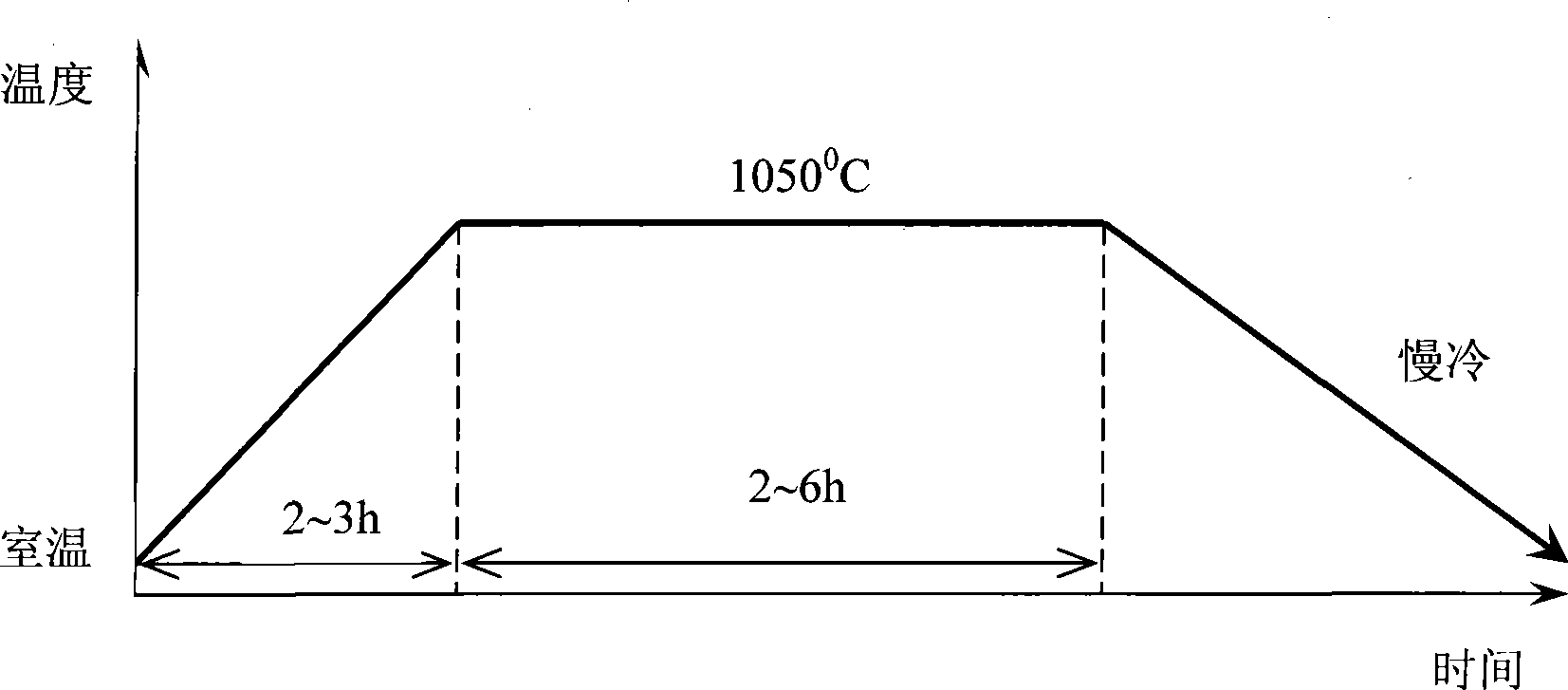

[0043] Process system such as image 3 As shown, the specific requirements are as follows.

[0044] (1) Place the workpiece in a resistance heating furnace (with or without atmosphere protection), and an appropriate gap should be left between the workpieces;

[0045] (2) Electric heating, heating rate 6 ~ 9 ℃ / minute;

[0046] (3) When the temperature rises to 1050°C, heat preservation starts. At this time, the temperature jump is ≤±5°C, and the heat preservation time is 2 to 6 hours (depending on the size of the workpiece);

[0047] (4) Cut off the power supply after the heat preservation is over, and keep the workpiece in the furnace to cool with the furnace;

[0048] (5) When the furnace temperature is less tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com