Electrolytic corrosion method of high strength and high toughness Fe-Mn-C series twinning induced plasticity steel

A technology of twin-induced plasticity and electrolytic corrosion, applied in the field of surface treatment of high-strength and high-toughness steel, can solve the problems of inability to obtain metallographic structure, change electrochemical properties, etc., and achieve clear corrosion structure, good reproducibility, and outstanding details. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

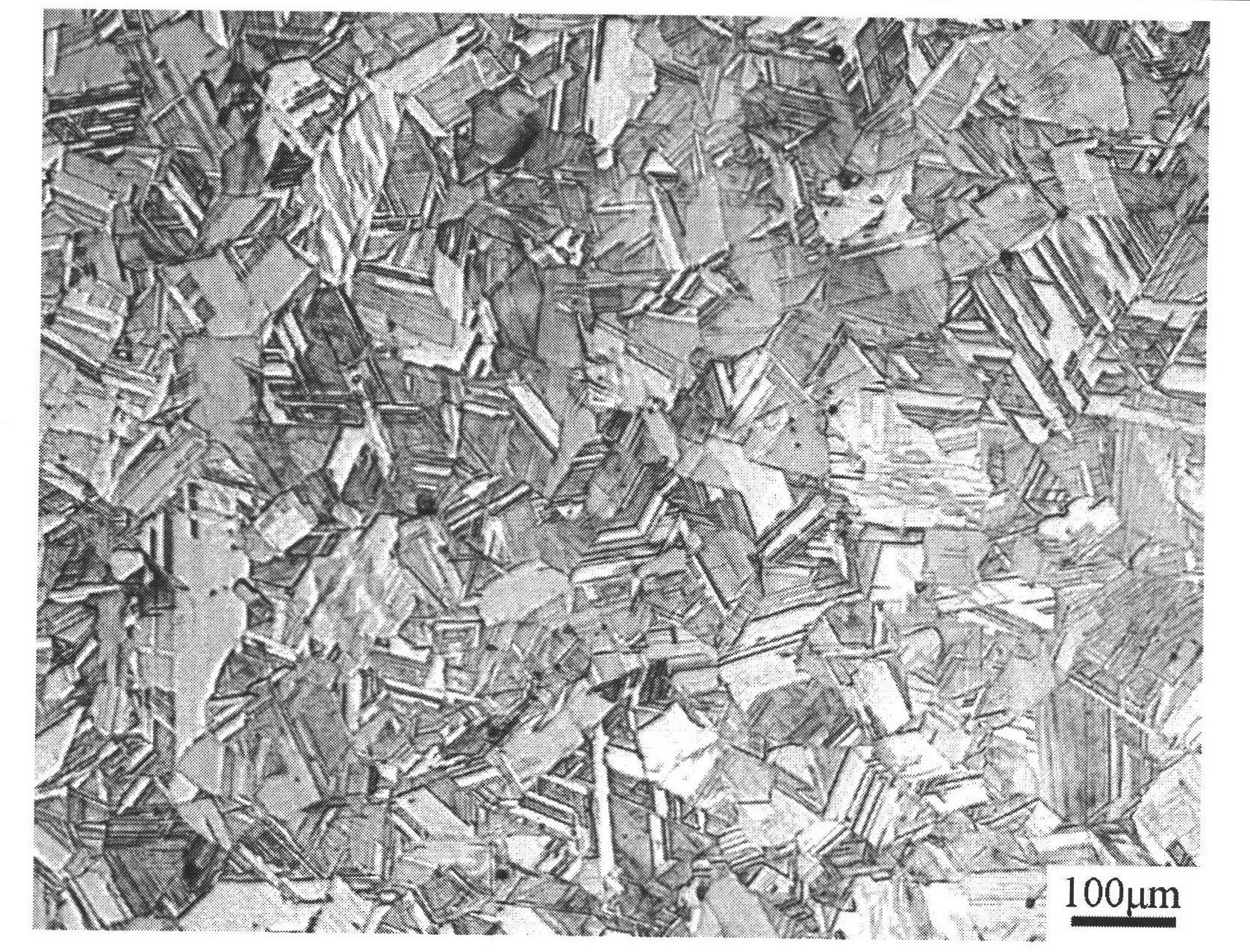

[0021] TWIP steel composition (by weight): 0.7% C, 17% Mn, and the rest are Fe and unavoidable impurities in the smelting process.

[0022] Experimental method: the first step, deploy corrosion electrolyte, measure perchloric acid, glacial acetic acid and glycerol by volume fraction (10% perchloric acid, 80% glacial acetic acid, 10% glycerol), inject electrolyzer and Stir evenly; in the second step, connect the TWIP steel sample to the anode of the electrolytic corrosion instrument, place it in the electrolyte together with the cathode of the electrolytic corrosion instrument, keep the distance between the cathode and the anode at 5cm, apply a working voltage of 30V, and a current density of 0.5A / cm2 , and use a stirrer to stir the electrolyte at a constant speed; the corrosion time is 120s. After the end, take out the sample, immediately put it in distilled water and ultrasonically clean it for 10s to remove the residual electrolyte, then rinse it with absolute ethanol and dry...

Embodiment 2

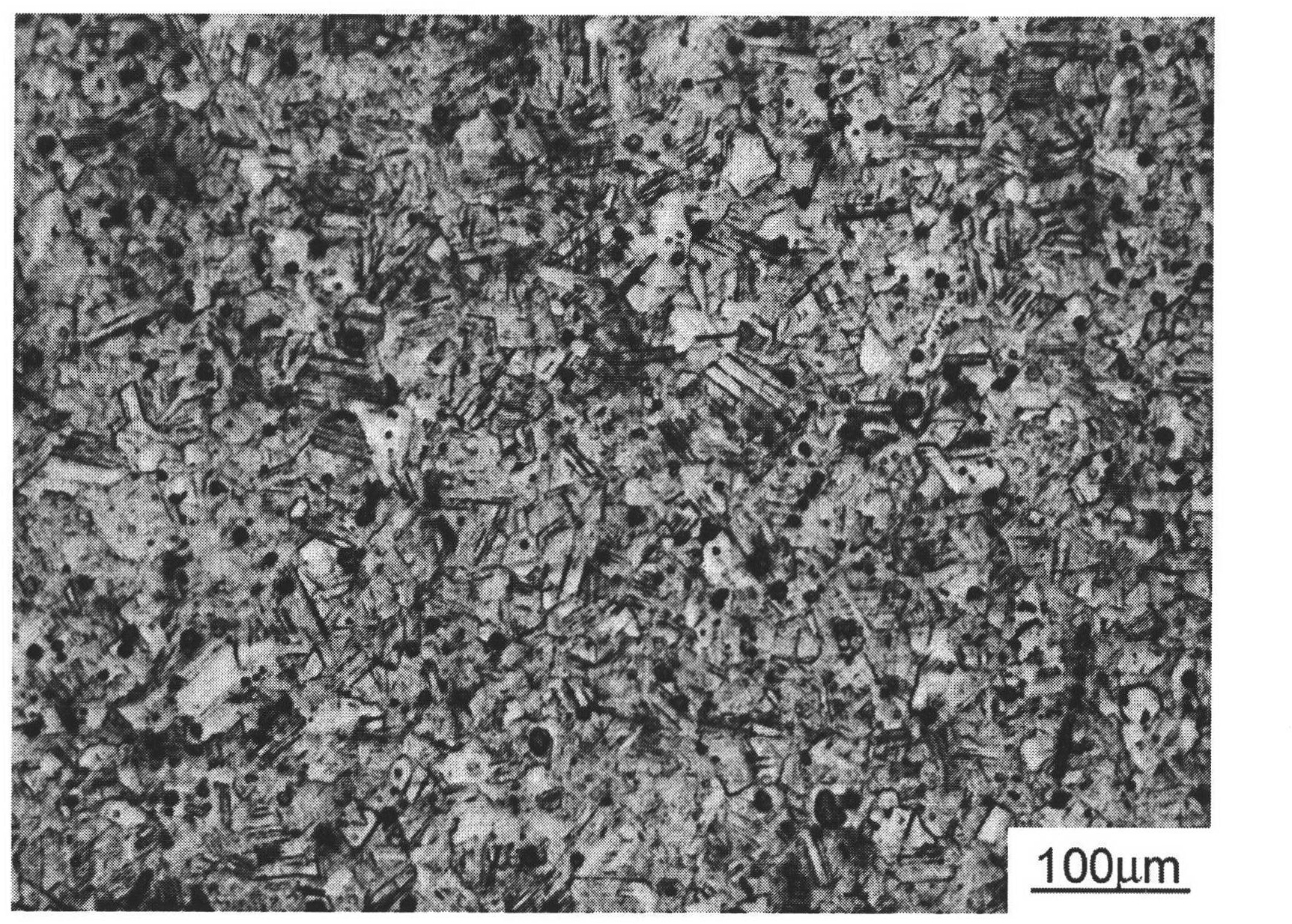

[0025] TWIP steel composition (by weight): 0.2% C, 24% Mn, and the rest are Fe and unavoidable impurities in the smelting process.

[0026] Experimental method: the first step is to prepare the corrosion electrolyte, measure the perchloric acid and glacial acetic acid according to the volume fraction (10% perchloric acid, 90% glacial acetic acid), inject them into the electrolytic tank and stir them evenly; the second step is to put the TWIP steel The sample is connected to the anode of the electrolytic corrosion instrument, placed in the electrolyte with the cathode of the electrolytic corrosion instrument, the distance between the cathode and the anode is kept 1cm, the applied working voltage is 45V, the current density is 1.5A / cm2, and the electrolyte is stirred at a constant speed with a stirrer; The time is 30s. After the end, take out the sample, put it in distilled water and ultrasonically clean it for 10s to remove the residual electrolyte, then rinse it with absolute e...

Embodiment 3

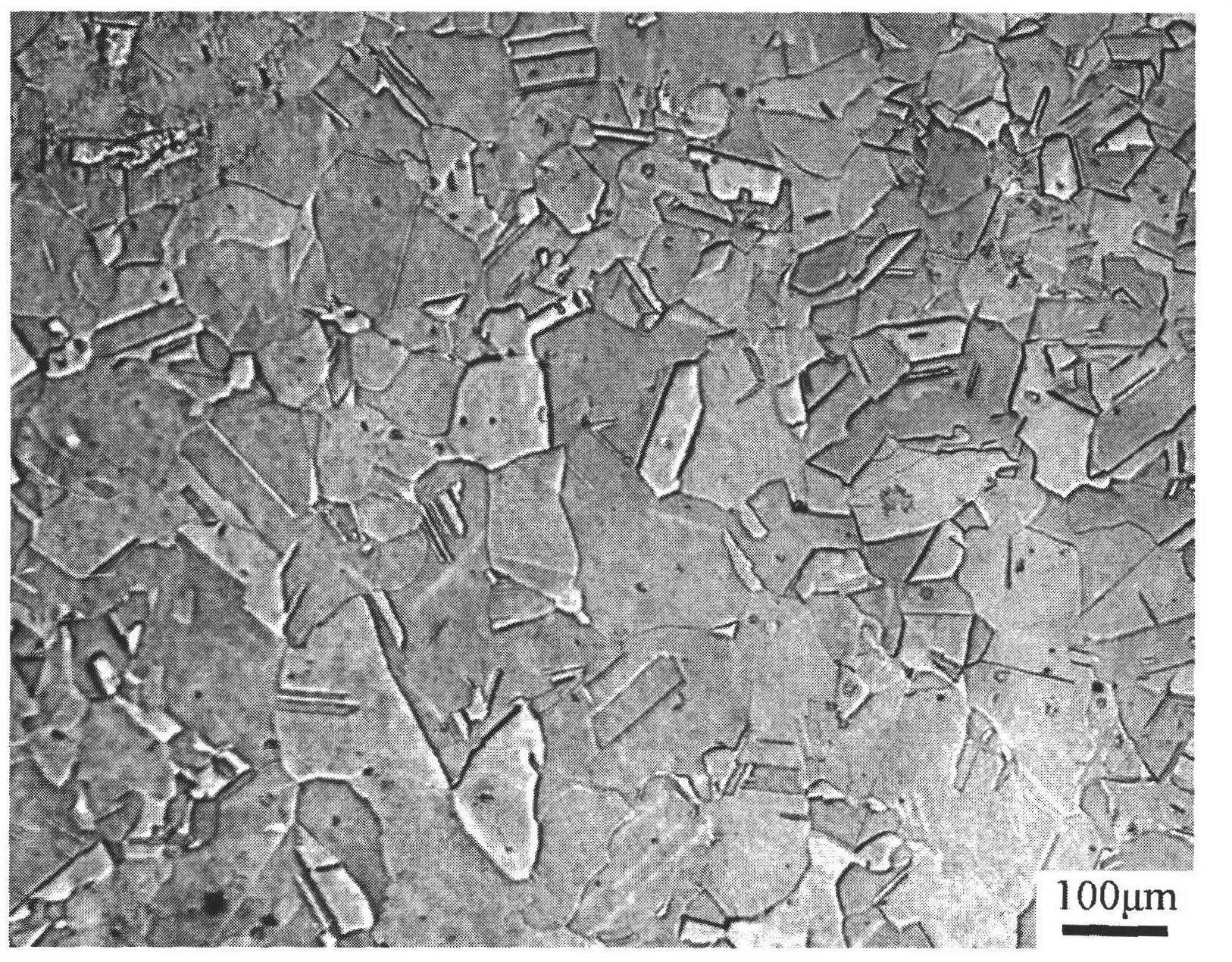

[0029] TWIP steel composition (by weight): 0.45% C, 21% Mn, and the rest are Fe and unavoidable impurities in the smelting process.

[0030] Experimental method: the first step, deploy corrosion electrolyte, measure perchloric acid, glacial acetic acid and glycerol by volume fraction (10% perchloric acid, 85% glacial acetic acid and 5% glycerol), inject electrolyzer and Stir evenly; in the second step, connect the TWIP steel sample to the anode of the electrolytic corrosion instrument, place it in the electrolyte together with the cathode of the electrolytic corrosion instrument, keep the distance between the cathode and the anode at 3cm, apply a working voltage of 37V, and a current density of 1A / cm2, And use a stirrer to stir the electrolyte at a constant speed; the corrosion time is 85s. After the end, take out the sample, put it in distilled water and ultrasonically clean it for 10s to remove the residual electrolyte, then rinse it with absolute ethanol and dry it with cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com