Automatic steel cord bulking detection device and use method thereof

A detection device, steel cord technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low detection efficiency, inconvenient semi-automatic operation, unfavorable work management of inspectors, etc., to achieve a large monitoring range and easy quality Traceable management, easy to inspect the effect of personnel management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

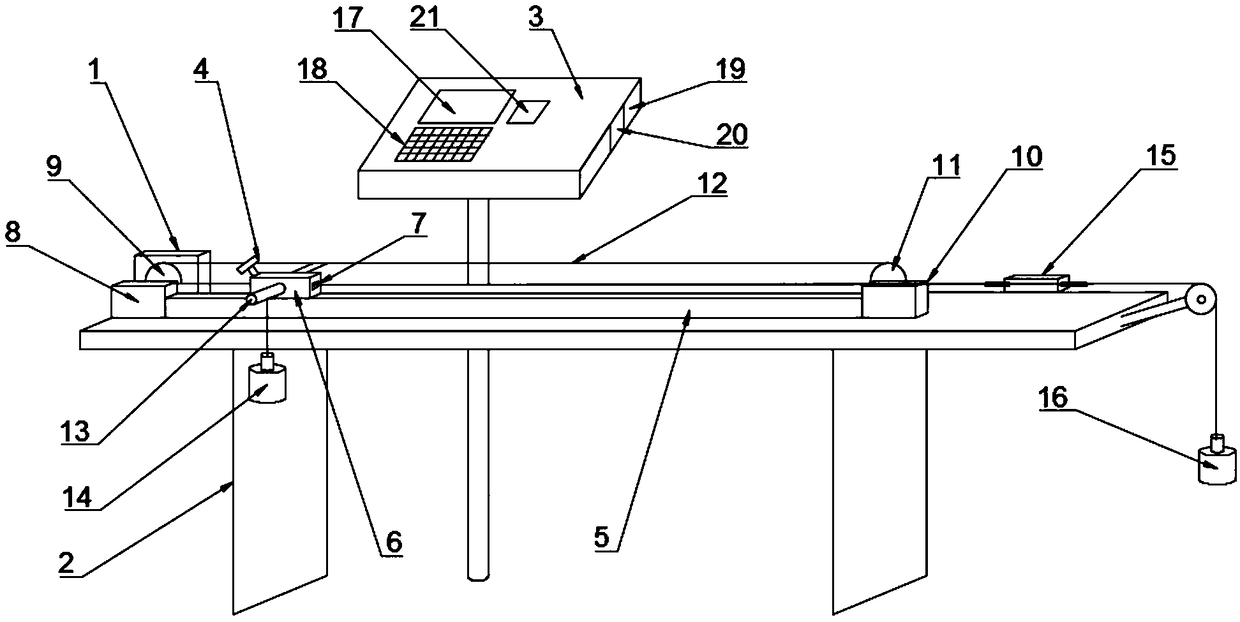

[0031] Such as figure 1 As shown, the automatic steel cord drum detection device provided by this embodiment includes a motor 1, a support 2, a console 3, and a high-definition camera 4. The support 2 is horizontally provided with a guide rail 5, and the guide rail 5 is provided with Slide block 6, the hollow part of the slide block 6 is provided with two detachable rubber sheets 7 up and down; the head of the bracket 2 is equipped with a cord clamp I 8 and a driving wheel 9, and the tail of the bracket 2 is equipped with Cord clamp II 10 and driven wheel 11, a transmission belt 12 is provided between the driving wheel 9 and the driven wheel 11, the output shaft of the motor 1 is connected to the driving wheel 9, and one side of the slider 6 is fixed to the transmission belt 12 Connected, the slider 6 is provided with a pressure rod 13, and a hanging hammer I14 is detachably suspended under the pressure rod 13; a cord pre-tension setting point 15 is set at the tail of the bracke...

Embodiment 2

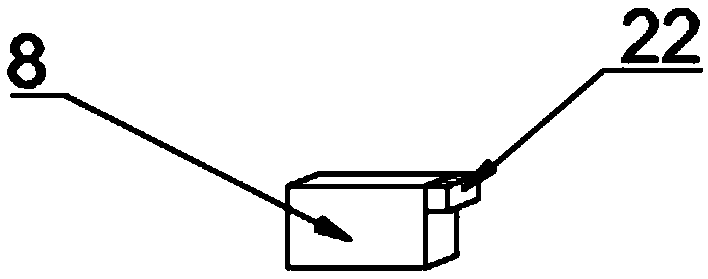

[0041] Such as figure 2 As shown, the automatic steel cord drum detection device provided by this embodiment is based on the embodiment 1, and a proximity switch is added to the cord clamp I 8 and the cord clamp II 10 facing the slider 6 22. The proximity switch 22 is electrically connected to the console 3.

Embodiment 3

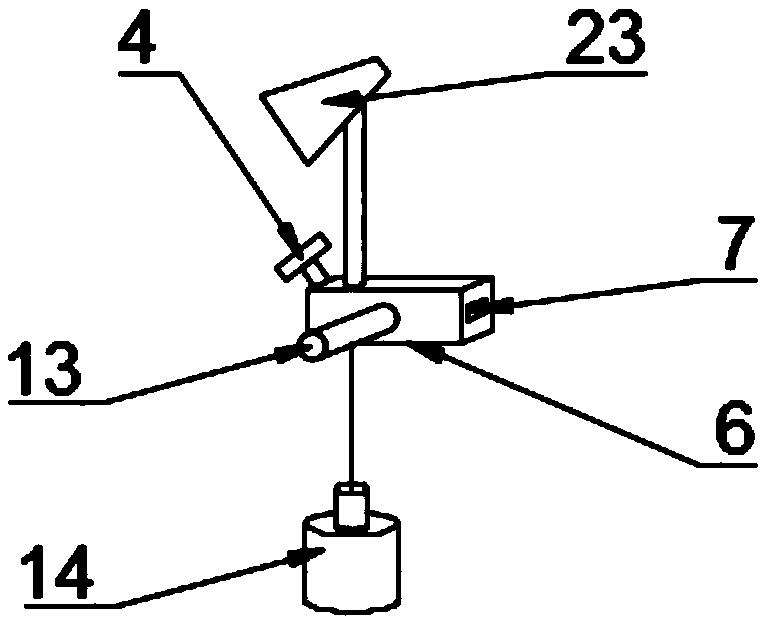

[0043] Such as image 3 As shown, the automated steel cord drum detection device provided by this embodiment is based on the first embodiment. The slider 6 is provided with an LED lamp 23. The illumination range of the LED lamp 22 is similar to that of the HD The photographing range of the camera 4 corresponds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com