Electroplated nylon material and preparation method thereof

A nylon and modified technology, which is applied in the field of electroplating nylon materials and its preparation, can solve the problems of increased roughness, decreased mechanical strength, poor impact toughness, etc., and can improve electroplatability, reduce adverse effects, and reduce shear fractures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

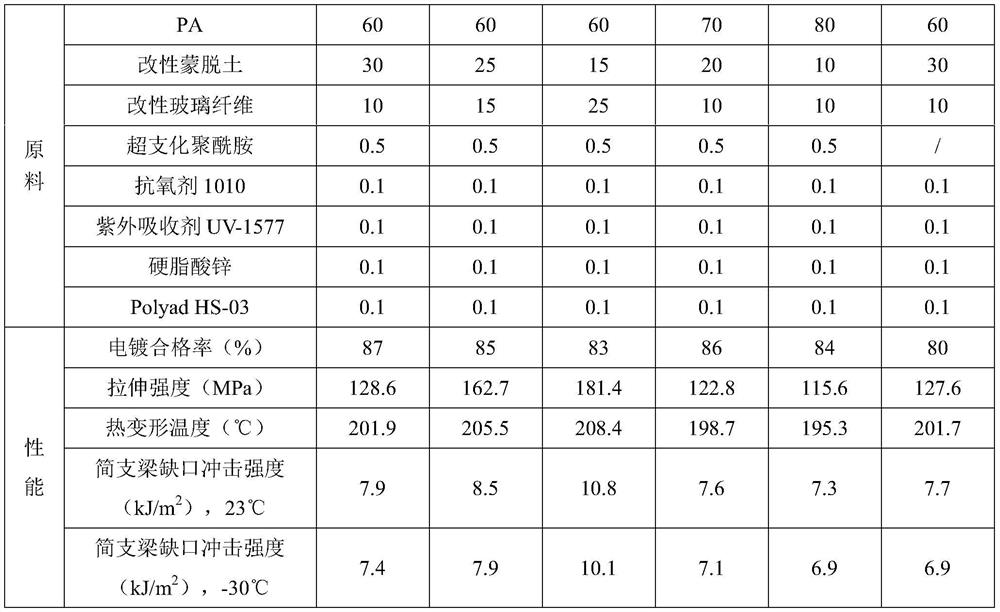

Examples

preparation example 1

[0081] Preparation of modified montmorillonite

[0082] (1) First, 100 parts by mass of montmorillonite (D 50 (The particle size is 0.2μm) vacuum drying at 100°C for 6 hours, and then cooling to room temperature under vacuum;

[0083] (2) Add 0.8 g of dry montmorillonite to 20 mL of toluene, and ultrasonically disperse at room temperature for 30 minutes to obtain a uniform suspension; then add 0.364 g of KH-550 to the suspension and mix ultrasonically for 10 minutes; react in a constant temperature tank at 90°C for 6 hours; The reaction solution was centrifuged at room temperature of 12000r / min, and the separated solid product was washed 3 times with absolute ethanol and dried in vacuum for 8 hours to obtain montmorillonite treated with silane coupling agent;

[0084] (3) Add 10 g of the montmorillonite treated with the silane coupling agent obtained in step (2) to deionized water, stir, filter, and then add to absolute ethanol, stir, let stand for 20 hours, filter, dry, and set asid...

preparation example 2

[0086] Preparation of montmorillonite treated with silane coupling agent

[0087] The preparation method is the same as step (1) and step (2) of Preparation Example 1.

preparation example 3

[0089] Preparation of montmorillonite treated with rare earth ions

[0090] According to the method of Preparation Example 1, the montmorillonite dried in step (1) is directly used in step (4) to adsorb rare earth ions to obtain rare earth ion-treated montmorillonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com