PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) blended material applicable to electroplating and preparation method thereof

A technology of blending and raw materials, which is applied in the field of plastic blending, can solve the problems of large fluctuations in the impact performance of PC/ABS materials, uneven particle size distribution of ABS, and failure to meet design expectations, so as to improve electroplating performance and reduce processing Required temperature, effect of reducing PC notch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

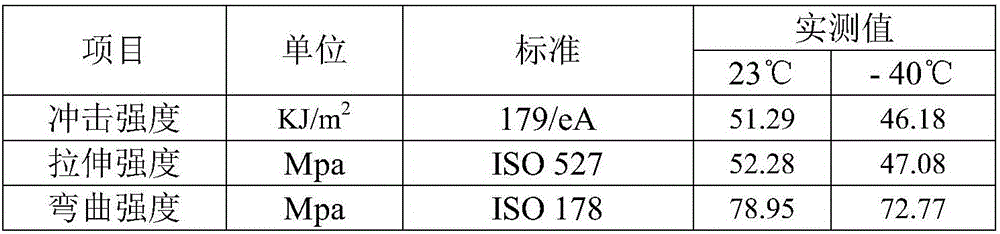

Embodiment 1

[0033] A PC / ABS blend material suitable for electroplating, comprising the following raw materials in weight ratio:

[0034] PC: 60 parts, ABS: 45 parts, lubricant: 0.5 parts, compatibilizer: 5 parts, processing aid: 3 parts, toughening agent: 5 parts, antioxidant: 0.28 parts, UV absorber: 1 part .

[0035] A PC / ABS blend material suitable for electroplating provided by the present invention is synthesized by the above weight ratio raw materials, and the PC used is a medium and high molecular weight polymer, so that PC and ABS resin have good compatibility under high and low temperature conditions The prepared PC / ABS blend material has a uniform particle size distribution, good impact resistance, and can effectively reduce the PC notch sensitivity, improve the electroplatability of ordinary PC, and make the PC / ABS blend material It has good high and low temperature retention; at the same time, by adding various additives to the PC / ABS blending raw material, the fluidity of th...

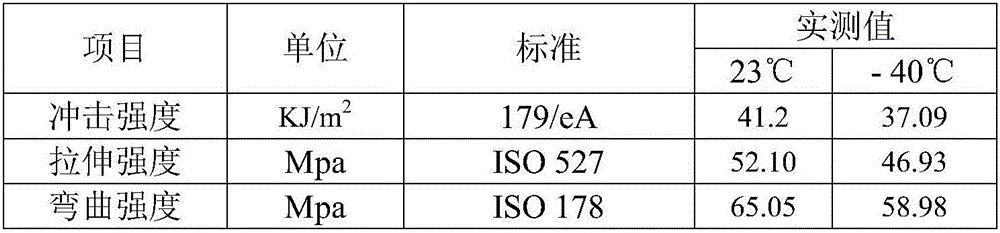

Embodiment 2

[0054] A PC / ABS blend material suitable for electroplating, comprising the following raw materials in weight ratio:

[0055] PC: 40 parts, ABS: 60 parts, lubricant: 0.1 part, compatibilizer: 10 parts, processing aid: 0.5 part, toughening agent: 3 parts, antioxidant: 0.5 part, UV absorber: 1 part .

[0056] A PC / ABS blend material suitable for electroplating provided by the present invention is synthesized by the above weight ratio raw materials, and the PC used is a medium and high molecular weight polymer, so that PC and ABS resin have good compatibility under high and low temperature conditions The prepared PC / ABS blend material has a uniform particle size distribution, good impact resistance, and can effectively reduce the PC notch sensitivity, improve the electroplatability of ordinary PC, and make the PC / ABS blend material It has good high and low temperature retention; at the same time, by adding various additives to the PC / ABS blending raw material, the fluidity of the...

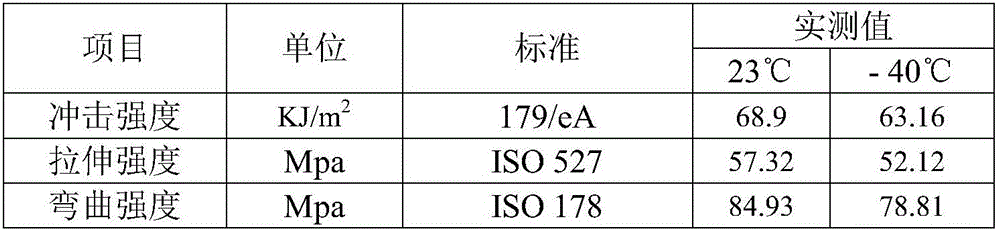

Embodiment 3

[0075] A PC / ABS blend material suitable for electroplating, comprising the following raw materials in weight ratio:

[0076] PC: 80 parts, ABS: 20 parts, lubricant: 1 part, compatibilizer: 1 part, processing aid: 5 parts, toughening agent: 10 parts, antioxidant: 0.1 part, UV absorber: 1 part .

[0077] A PC / ABS blend material suitable for electroplating provided by the present invention is synthesized by the above weight ratio raw materials, and the PC used is a medium and high molecular weight polymer, so that PC and ABS resin have good compatibility under high and low temperature conditions The prepared PC / ABS blend material has a uniform particle size distribution, good impact resistance, and can effectively reduce the PC notch sensitivity, improve the electroplatability of ordinary PC, and make the PC / ABS blend material It has good high and low temperature retention; at the same time, by adding various additives to the PC / ABS blending raw material, the fluidity of the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com