Strip steel continuous hot galvanizing method

A technology of hot-dip galvanizing and strip steel, which is applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., to achieve the effect of reducing zinc skin defects, improving platability, and excellent platability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

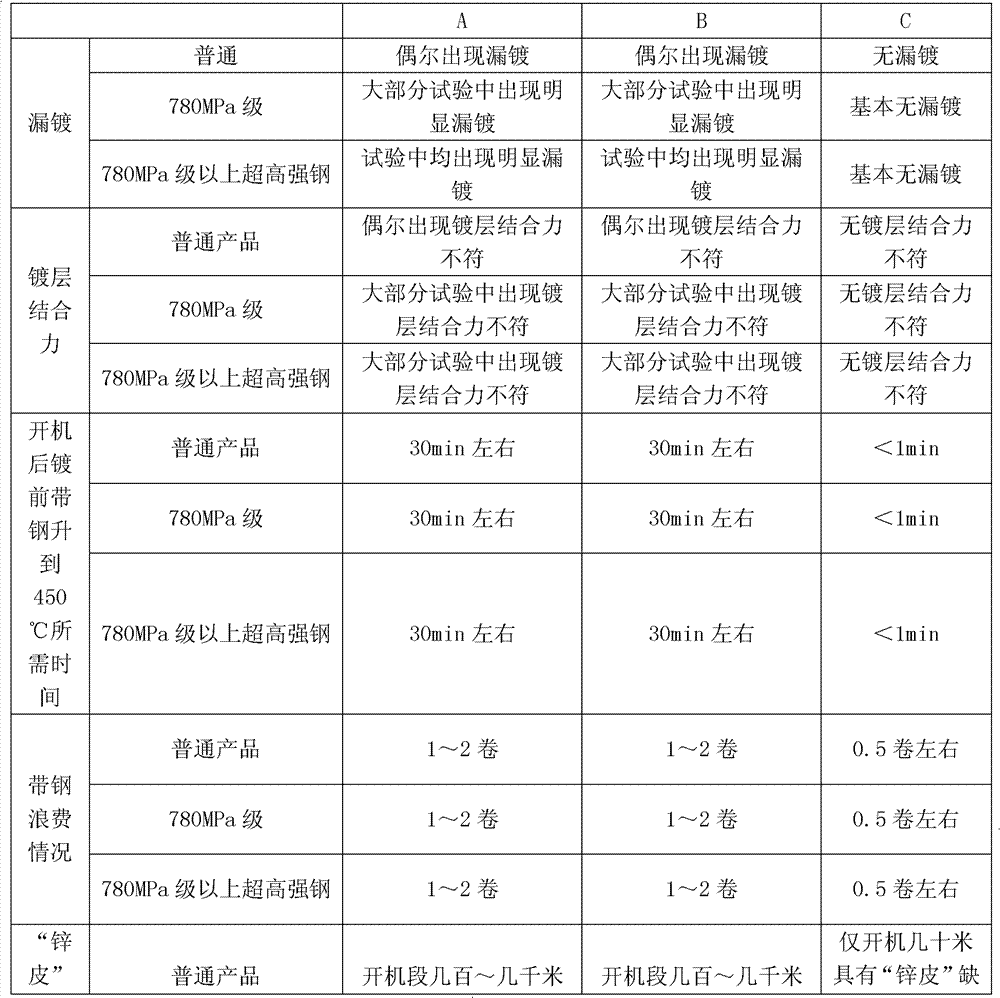

Examples

Embodiment Construction

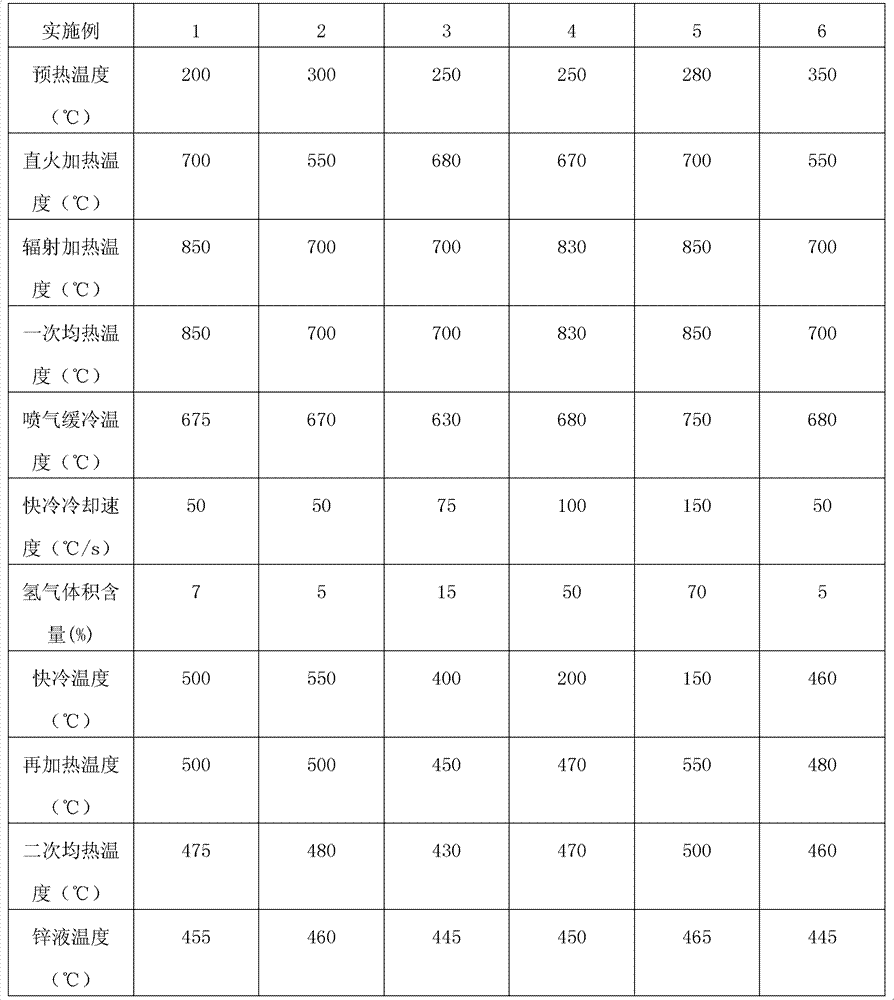

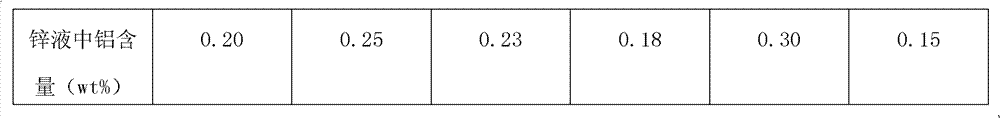

[0028] Adopt following steps to carry out hot-dip galvanizing to strip steel, the concrete process parameter of each step in this case embodiment 1-6 sees Table 1:

[0029] (1) Preheat the strip steel after cleaning, and the preheating temperature is 200-350°C;

[0030] (2) The strip steel is heated to 550-700°C by means of direct contact with the short flame of natural gas combustion to the strip steel (expressed as direct fire heating temperature in Table 1);

[0031] (3) Continue to heat the strip to 700-850°C by means of radiant tube heating;

[0032] (4) Carry out radiant tube soaking to strip steel, soaking temperature is 700~850 ℃ (represented as primary soaking temperature in table 1);

[0033] (5) Slowly cool the strip steel to 630-750°C by spraying air;

[0034] (6) The strip steel is rapidly cooled to 150-550°C by using nitrogen-hydrogen mixed gas with a hydrogen volume content of 5-70%, and the cooling rate is 50-150°C / s;

[0035] (7) Using an electromagnetic in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com