Medium manganese steel hot dipping method

A technology of hot-dip plating and manganese steel, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve problems such as poor coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

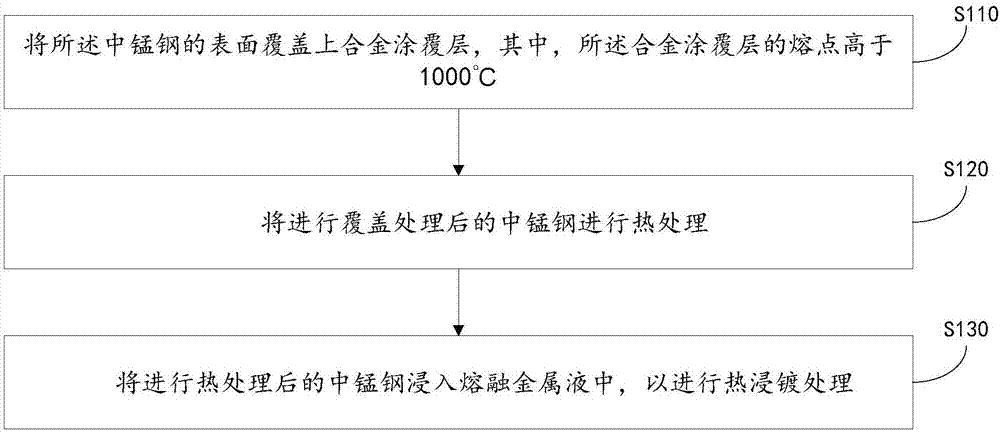

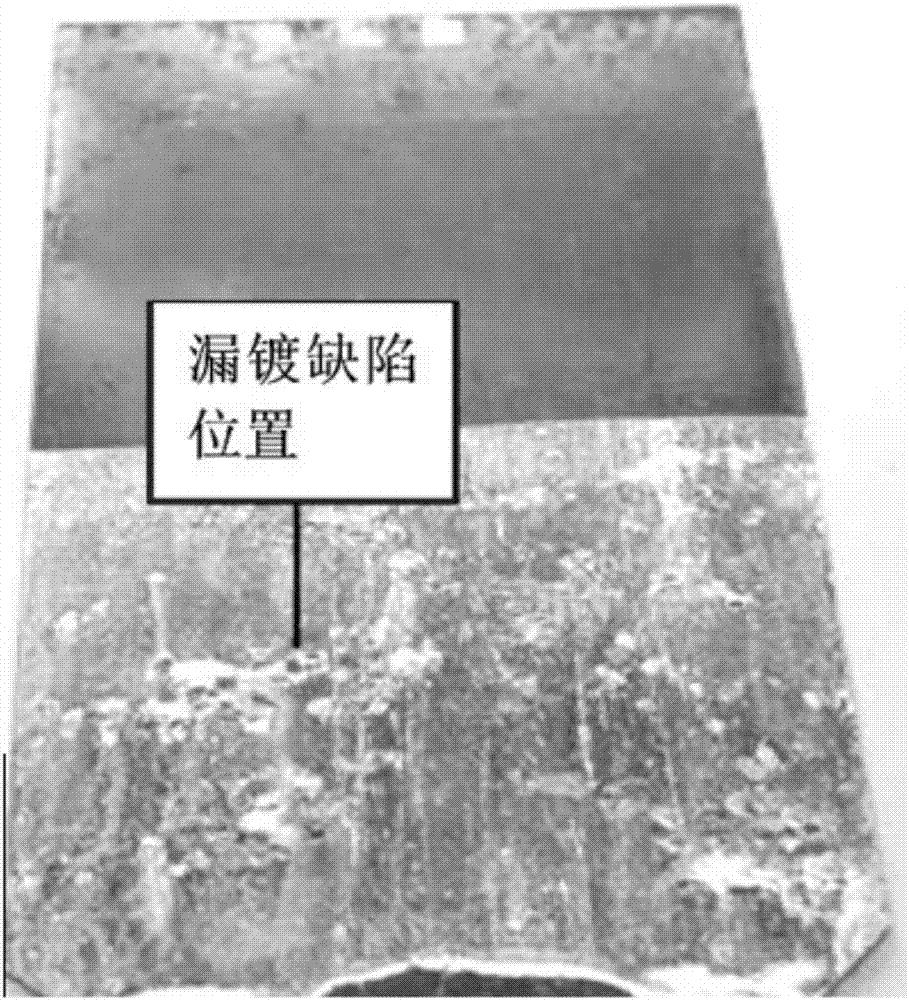

[0029] The embodiment of the present invention provides a method for hot-dip coating of medium manganese steel, which is used to improve the technology of poor coating quality due to the easy formation of oxides in the heat treatment process of the prior art medium manganese steel hot-dip coating method question.

[0030] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

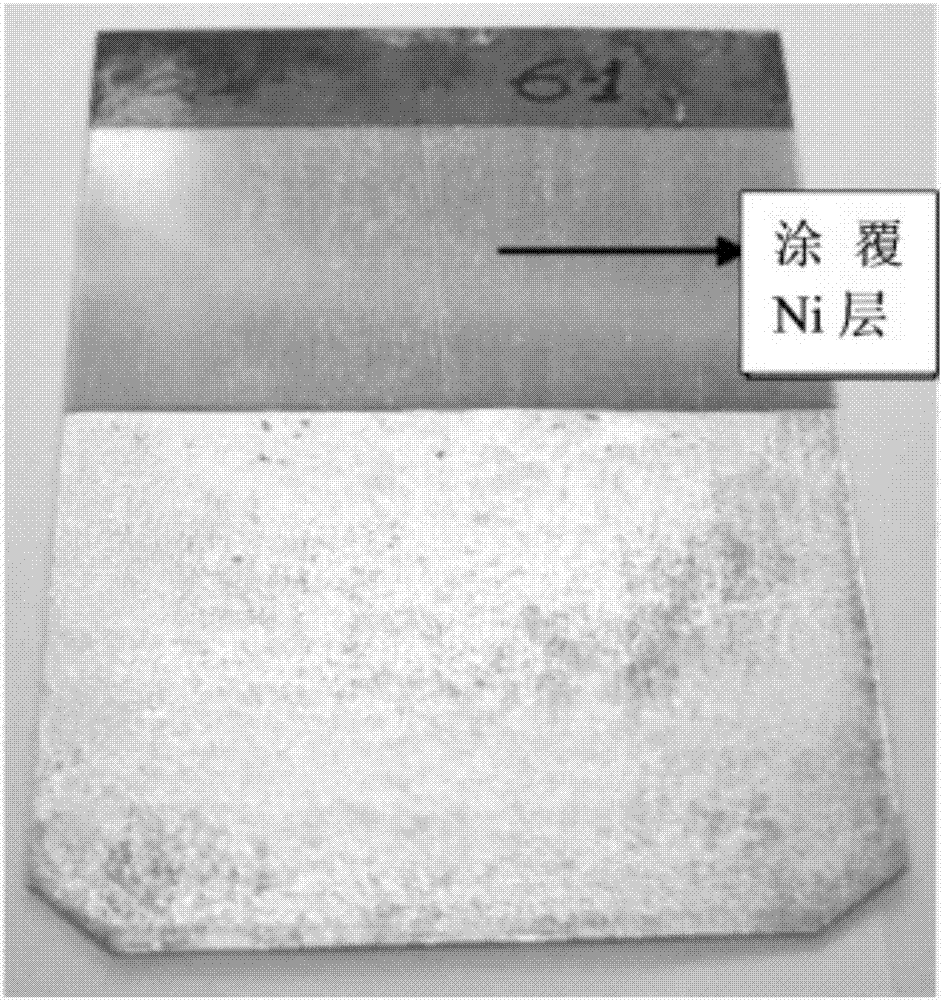

[0031] A method for hot-dipping medium manganese steel, the mass fraction of elements in the medium manganese steel is: 0.5%≥[C]≥0.1%, 2.0%≥[Si]≥0.2%, 10%≥[Mn]≥ 4%, 2%≥[Al]≥0.2%, the method includes: covering the surface of the medium manganese steel with an alloy coating layer, wherein the melting point of the alloy coating layer is higher than 1000°C; The covered medium manganese steel is subjected to heat treatment; the heat treated medium manganese steel is immersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com