Novel elastic conductive alloy and its preparing method

An elastic conductive and alloy technology, applied in the field of metal materials, can solve the problems of increasing process cost, influence of material application, influence of material performance, etc., and achieve the effect of high strength, excellent process performance and good conductivity stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

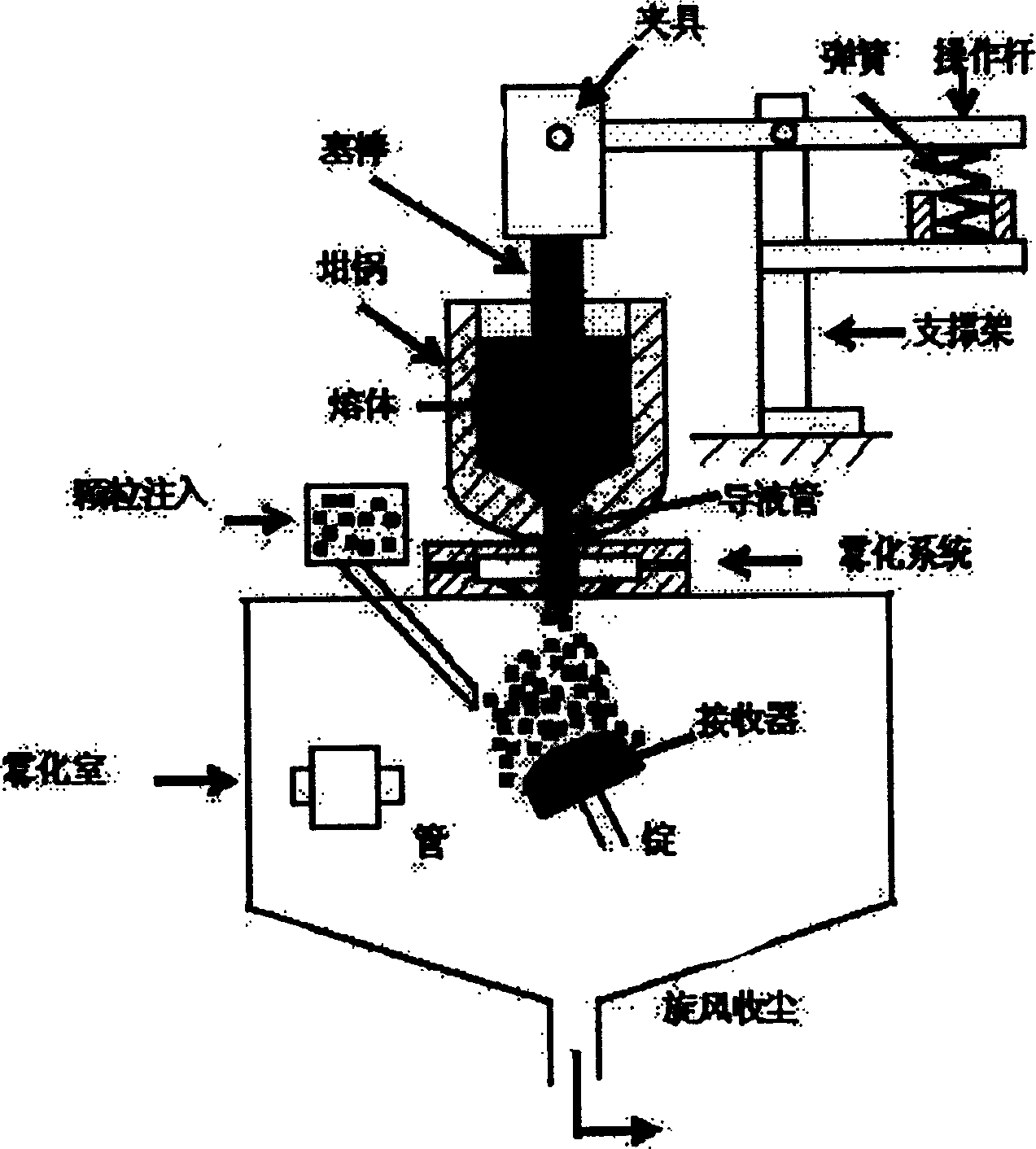

Embodiment 1

[0013] Example 1: Preparation of spray-formed Cu-6Ni-4Sn-0.05Y alloy and its spring sheet. The preparation process of Cu-6Ni-4Sn-0.05Y alloy is as described above. The superheat of the melt is about 150°C, and the inner diameter of the catheter is φ4mm; the atomizing gas is nitrogen, and the initial set pressure is 1.8MPa; the alloy liquid flow is atomized into fine droplets, and the droplets are then deposited on a distance from the atomizer On a rotating copper substrate with a diameter of about 360mm, the rotation speed of the substrate is 8rpm, and the gas / solution flow ratio is about 0.5m 3 / kg. The deposited blank is quenched in solution water at 800°C for 3min, cold-rolled with 90% deformation, aged at 350°C for 1h, and then pressed into a spring sheet.

Embodiment 2

[0014] Example 2: Preparation of spray-formed Cu-9Ni-6Sn-0.5Y alloy and its spring sheet. The preparation process of Cu-9Ni-6Sn-0.5Y alloy is as described above. The superheating degree of the melt is about 140°C, and the inner diameter of the catheter is φ4mm; the atomizing gas is nitrogen, and the initial setting pressure is 1.8MPa; the alloy liquid flow is atomized into fine droplets, and the droplets are then deposited on a distance from the atomizer On a rotating copper substrate with a diameter of about 350mm, the rotation speed of the substrate is 8rpm, and the gas / solution flow ratio is about 0.4m 3 / kg. The deposited blank is quenched in solution water at 850°C for 3min, cold-rolled with 90% deformation, aged at 400°C for 1h, and pressed into a spring sheet.

Embodiment 3

[0015] Example 3: Preparation of spray-formed Cu-15Ni-8Sn-3.5Y alloy and its spring sheet. The preparation process of Cu-15Ni-8Sn-3.5Y alloy is as described above. The superheat of the melt is about 150°C, and the inner diameter of the catheter is φ4mm; the atomizing gas is nitrogen, and the initial set pressure is 1.8MPa; the alloy liquid flow is atomized into fine droplets, and the droplets are then deposited on a distance from the atomizer On a rotating copper substrate with a diameter of about 370mm, the rotation speed of the substrate is 8rpm, and the gas / solution flow ratio is about 0.6m 3 / kg. The deposited blank is quenched in solution water at 900°C for 3 minutes, cold-rolled with 90% deformation, aged at 450°C for 1 hour, and pressed into a spring sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com