High manganese hot-dip galvanized steel sheet containing rare earth and manufacture method thereof

A technology of hot-dip galvanized steel sheet and high manganese, which is applied in the field of hot-dip galvanized steel sheet, which can solve the problems of adverse effects of large-scale production, decrease of material thermoplasticity, and large shrinkage of molten steel during solidification, so as to achieve low material cost and improved continuous casting performance , the effect of delaying the formation of twins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0052] The composition of the embodiment of the present invention is smelted, hot-rolled, cold-rolled, annealed, pickled, and hot-dip galvanized to obtain a rare-earth-containing high-manganese hot-dip galvanized steel sheet. The composition is shown in Table 1, and its annealing process, surface treatment process, The pickling process and hot-dip galvanizing process are shown in Table 2, and the mechanical properties, delayed cracking characteristics, and coating quality results are shown in Table 3.

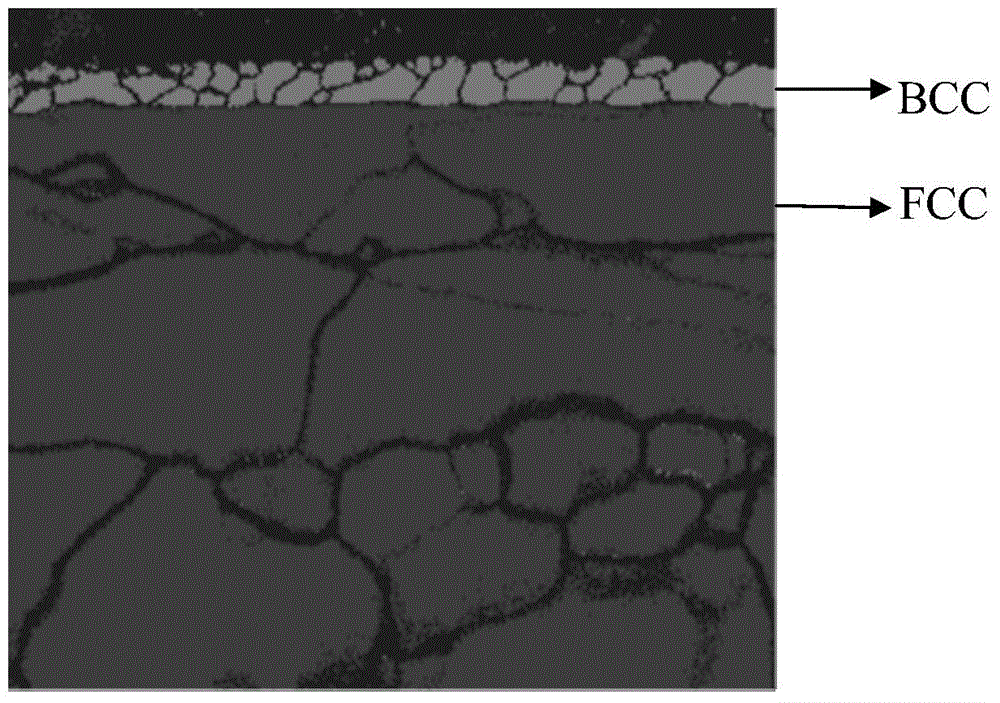

[0053] As can be seen from Table 3, the rare earth-containing high manganese hot-dip galvanized steel sheet obtained by the present invention has a structure at room temperature of 100% austenite; a recrystallization fraction of 80% to 95%; 950~1100MPa, the elongation rate is above 50%, and the coating quality is qualified.

[0054] figure 1 , figure 2 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com