Method for silvering kovar alloy interconnection piece

A technology of interconnection sheet and alloy, which is applied in the field of interconnection of solar cells for aerospace, can solve the problems of no improvement in the tensile strength of interconnection sheet and battery sheet, insufficient plating ability and deep plating ability of the coating, high cost of ion implantation process, etc., to achieve The effect of low cost, high yield and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

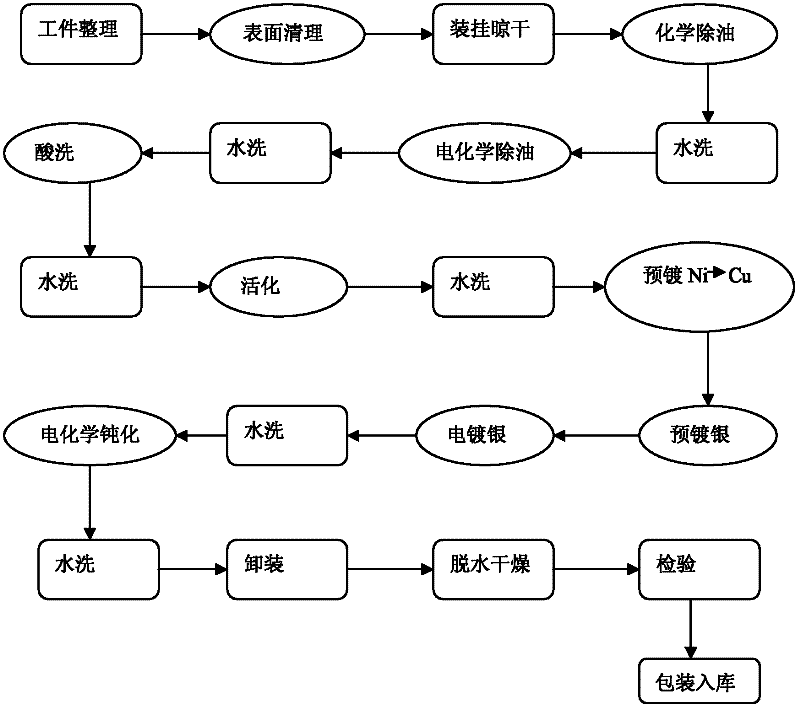

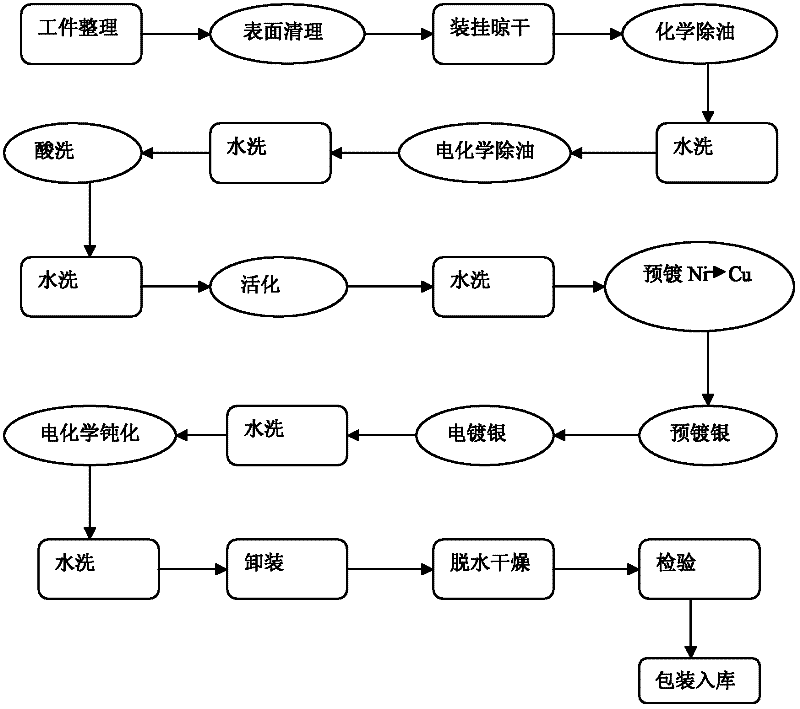

[0022] Combined with the fact that the 0.02mm Kovar alloy interconnect sheet is thin, light, small and complex in shape, the workpiece should be handled with care during operation, and it should be shaken up and down in the solution to improve the workpiece processing and electroplating effect; Kovar alloy interconnect sheet is silver-plated The operation steps include: ⑴ surface screening and wiping cleaning, ⑵ joint degreasing, ⑶ pickling activation, ⑷ pre-plating treatment, ⑸ pre-silvering, ⑹ electro-silvering and ⑺ electrochemical passivation, until unloading, dehydration and drying, inspection, Finally packed into warehouse. Specific steps are as follows:

[0023] ⑴Surface screening and wiping and cleaning: According to the size of the required interconnection sheet, select qualified workpieces from the cut 0.02mm thick Kovar alloy interconnection sheet, and carry out workpiece finishing and surface cleaning to ensure flatness and no edge corners. For burrs, wipe and cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com