TRIP steel plate for high strength cold rolling hot dip galvanizing and preparation thereof

A hot-dip galvanizing, high-strength technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as tensile strength reduction, achieve refined grain, excellent coating performance, grain size Refinement effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The manufacture method of high-strength cold-rolled hot-dip galvanized TRIP steel of the present invention:

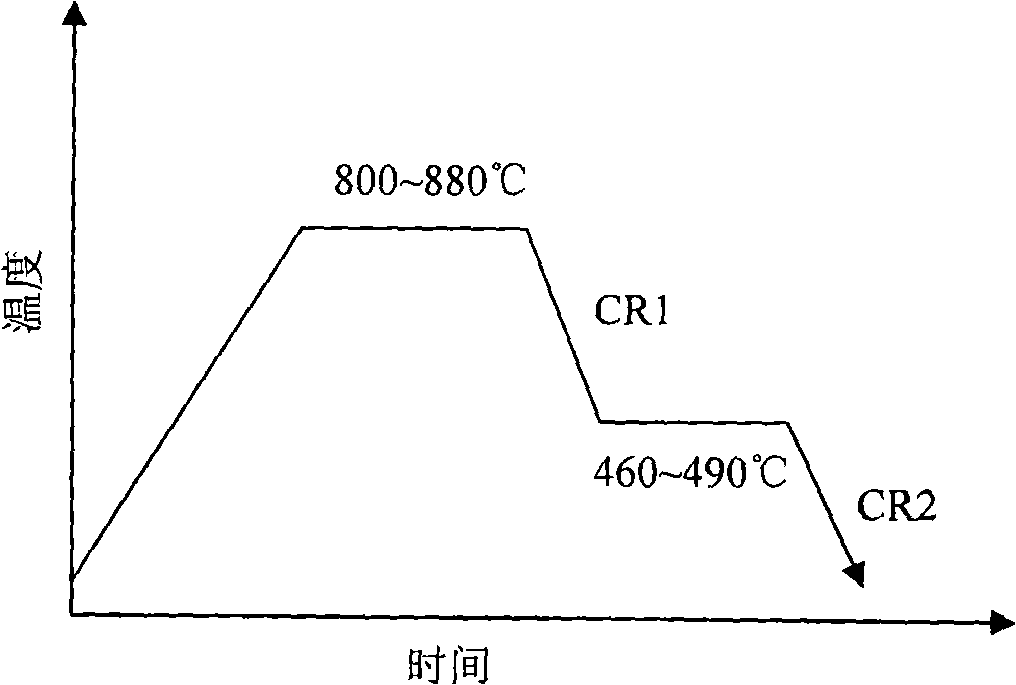

[0032] Firstly, smelting is carried out according to the design composition. After forging, the billet is hot-rolled into a thin plate. The final rolling temperature of hot rolling is 860-900°C, and the coiling temperature is 600-700°C; the reduction rate of cold rolling is 50-70%; two-phase zone annealing The temperature is 800-880°C, the annealing time in the two-phase zone is 60-200s, the cooling rate CR1 from the annealing temperature to the zinc pool temperature is 20-50°C / s; the zinc pool temperature is 450-470°C, and the galvanizing time is 10-60s, and the cooling rate after galvanizing is CR220-50°C / s to cool to room temperature, so as to obtain high-strength cold-rolled hot-dip galvanized TRIP steel. figure 1 For the annealing process, Table 1 is the chemical composition, and Table 2 is the mechanical properties.

[0033] Table 1 chemical composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com