Titanium silicon nitride core-spun yarn

A technology of titanium silicon nitride and cored wire, which is applied in the field of cored wire, can solve the problems of low recovery rate, instability, nodulation, etc., and achieve the effects of preventing grain growth, improving strength, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

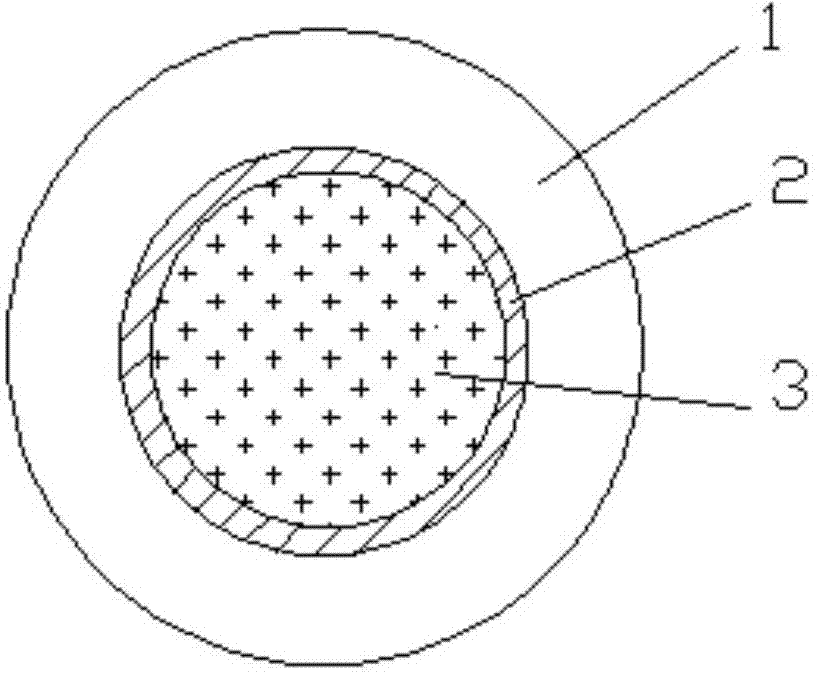

[0014] A preferred embodiment 1 of a titanium nitride silicon cored wire of the present invention, as figure 1 As shown, it includes a core layer 3 and a steel skin layer 1 wrapped outside the core layer 3, and the core layer 3 is a titanium silicon nitride alloy layer. Steel mills are now producing steel production adding titanium nitride silicon alloys. Because the specific gravity of titanium silicon nitride alloy is too light, in the process of adding, it floats on the surface of molten steel and is combined with steel slag to be oxidized, causing the recovery rate of vanadium and titanium to be low (20% on average), and the titanium content in steel is 0.0038%, which cannot reach to internal quality control requirements. The titanium-silicon nitride alloy is fed into the steel in the form of a cored wire at the argon blowing station. On the one hand, the alloy can quickly enter the molten steel to prevent the alloy from being oxidized by steel slag on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com