Calcium and cerium added flame-retardant magnesium alloy and preparation method thereof

A magnesium alloy and calcium addition technology, which is applied in the field of cerium flame-retardant magnesium alloy and its preparation and calcium addition, can solve the problems of harm to the human body, decreased toughness, thermal cracking, etc., and achieve the effects of cost saving, good metamorphism and refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

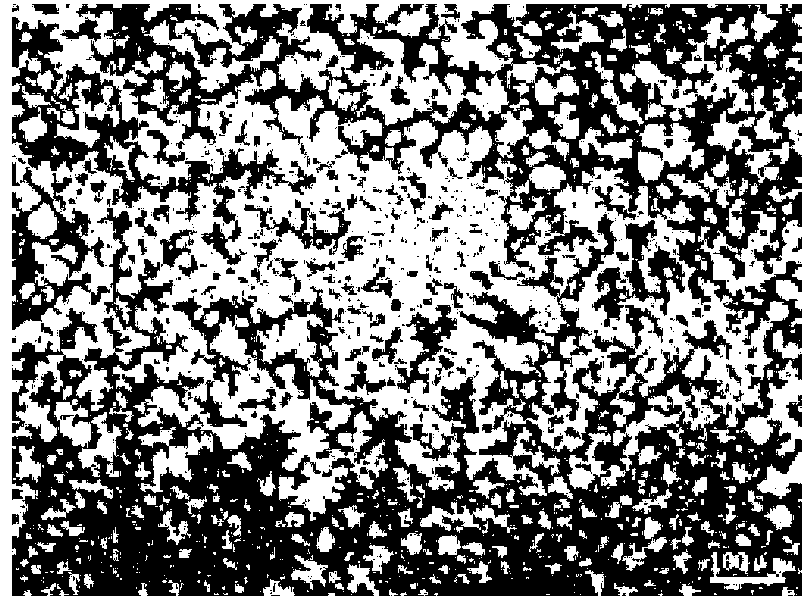

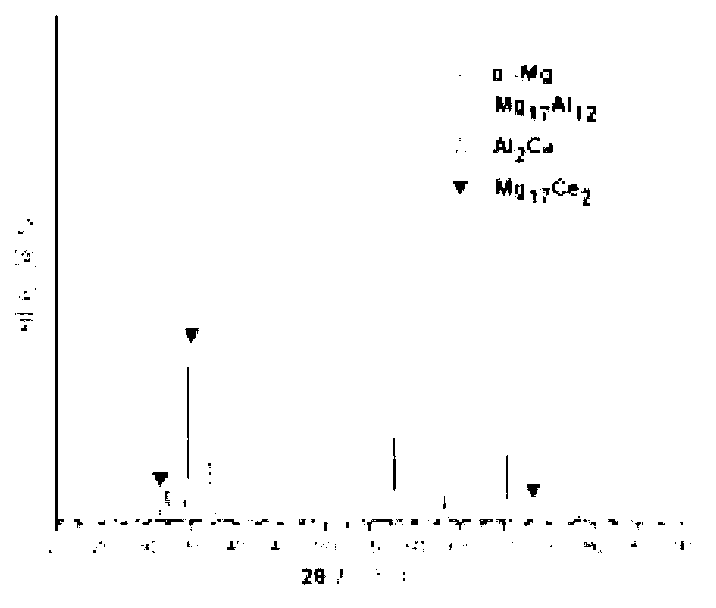

Image

Examples

Embodiment 1

[0026] 1. To prepare the components of AZ91D-2.5Ca-1.2Ce (wt.%), weigh 289.75g of magnesium ingot with a purity of 99.99%, 31.01g of an aluminum ingot with a purity of 99.95%, and 2.70g of a zinc ingot with a purity of 99.95%. , 1.18g of manganese ingot with a purity of 99.99%, 30.94g of Mg-29.9Ca (wt.%) master alloy, 14.42g of Mg-30.8Ce (wt.%) master alloy (the master alloy materials involved in the present invention are all purchased from Hunan Institute of Nonferrous Metals);

[0027] 2. Set the heating temperature of the crucible resistance furnace to 750°C. When the crucible is preheated to 500°C, add the pre-weighed magnesium ingots in step 1 to the crucible, and then make the crucible at a volume percentage of 99.5% CO 2 and 0.5% SF 6 Put it into the resistance furnace under the atmosphere of mixed protective gas, and add other pre-weighed raw materials after the magnesium ingots are completely melted;

[0028] 3. After all the raw materials in the crucible are melted...

Embodiment 2

[0033] 1. To prepare the components of AZ91D-2.2Ca-1.0Ce (wt.%), weigh 294.93g of magnesium ingot with a purity of 99.99%, 32.00g of an aluminum ingot with a purity of 99.95%, and 2.66g of a zinc ingot with a purity of 99.95%. , 1.18g of manganese ingot with a purity of 99.99%, 27.22g of Mg-29.9Ca (wt.%) master alloy, and 12.01g of Mg-30.8Ce (wt.%) master alloy;

[0034] 2. Set the heating temperature of the crucible resistance furnace to 750°C. When the crucible is preheated to 500°C, add the pre-weighed magnesium ingots in step 1 to the crucible, and then make the crucible at a volume percentage of 99.5% CO 2 and 0.5% SF 6 Put it into the resistance furnace under the atmosphere of mixed protective gas, and add other pre-weighed raw materials after the magnesium ingots are completely melted;

[0035] 3. After all the raw materials in the crucible are melted, stir the magnesium alloy melt, remove the dross on the surface of the melt, control the temperature at 710~720°C and l...

Embodiment 3

[0039] 1. To prepare the components of AZ91D-2.3Ca-1.1Ce (wt.%), weigh 291.55g of magnesium ingot with a purity of 99.99%, 32.93g of an aluminum ingot with a purity of 99.95%, and 2.74g of a zinc ingot with a purity of 99.95%. , 1.11g of manganese ingot with a purity of 99.99%, 28.46g of Mg-29.9Ca (wt.%) master alloy, and 13.21g of Mg-30.8Ce (wt.%) master alloy;

[0040] 2. Set the heating temperature of the crucible resistance furnace to 750°C. When the crucible is preheated to 500°C, add the pre-weighed magnesium ingots in step 1 to the crucible, and then make the crucible at a volume percentage of 99.5% CO 2 and 0.5% SF 6 Put it into the resistance furnace under the atmosphere of mixed protective gas, and add other pre-weighed raw materials after the magnesium ingots are completely melted;

[0041] 3. After all the raw materials in the crucible are melted, stir the magnesium alloy melt, remove the dross on the surface of the melt, control the temperature at 710~720°C and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com