A magnesium alloy low-frequency pulsed magnetic field assisted semi-continuous casting mold and its application

A casting crystallizer and low-frequency pulse technology, which is applied in the field of magnesium alloy low-frequency pulsed magnetic field-assisted semi-continuous casting crystallizers, can solve the problems of insignificant core structure refinement, coarse grain size and uneven structure of the ingot, etc. problem, to achieve the effect of grain refinement, good surface quality and good refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

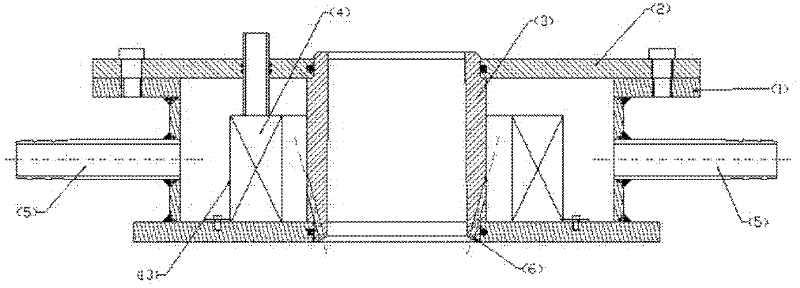

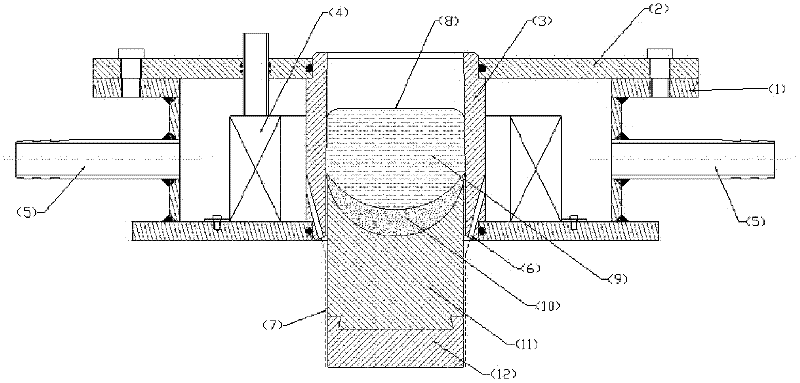

Method used

Image

Examples

Embodiment 1

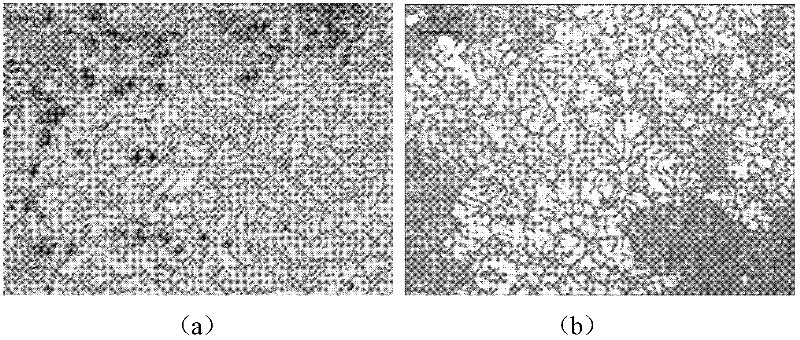

[0037] In the present embodiment, the smelting alloy is AZ80 alloy, and the size of the crystallizer (that is, the inner diameter of the inner sleeve of the crystallizer) is The casting temperature is 730°C, the cooling water flow rate is 380-420ml / s, the casting speed is 152mm / min, the pulse voltage is 120-200V, and the pulse frequency is 2.5-10Hz. Such as image 3 As shown, according to this process, a magnesium alloy semi-continuous ingot with good surface quality, uniform internal structure and fine grain can be obtained.

Embodiment 2

[0039] In the present embodiment, the smelting alloy is AZ91 alloy, and the crystallizer size (i.e. the inner diameter of the inner sleeve of the crystallizer) is The casting temperature is 730°C, the cooling water flow rate is 400-650ml / s, the casting speed is 80-120mm / min, the pulse voltage is 120-200V, and the pulse frequency is 2.5-10Hz. According to this process, a magnesium alloy semi-continuous ingot with good surface quality, uniform internal structure and obviously refined dendrites can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com