Al-M-B grain refiner for casting Al-Si alloy and preparation method thereof

A technology of casting aluminum-silicon alloy and grain refiner, which is applied in the field of aluminum alloy smelting, can solve the problems of poor refinement effect, high Nb content, and easy settlement failure of cast aluminum-silicon alloy, so as to achieve good refinement effect and equipment The effect of simple conditions and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

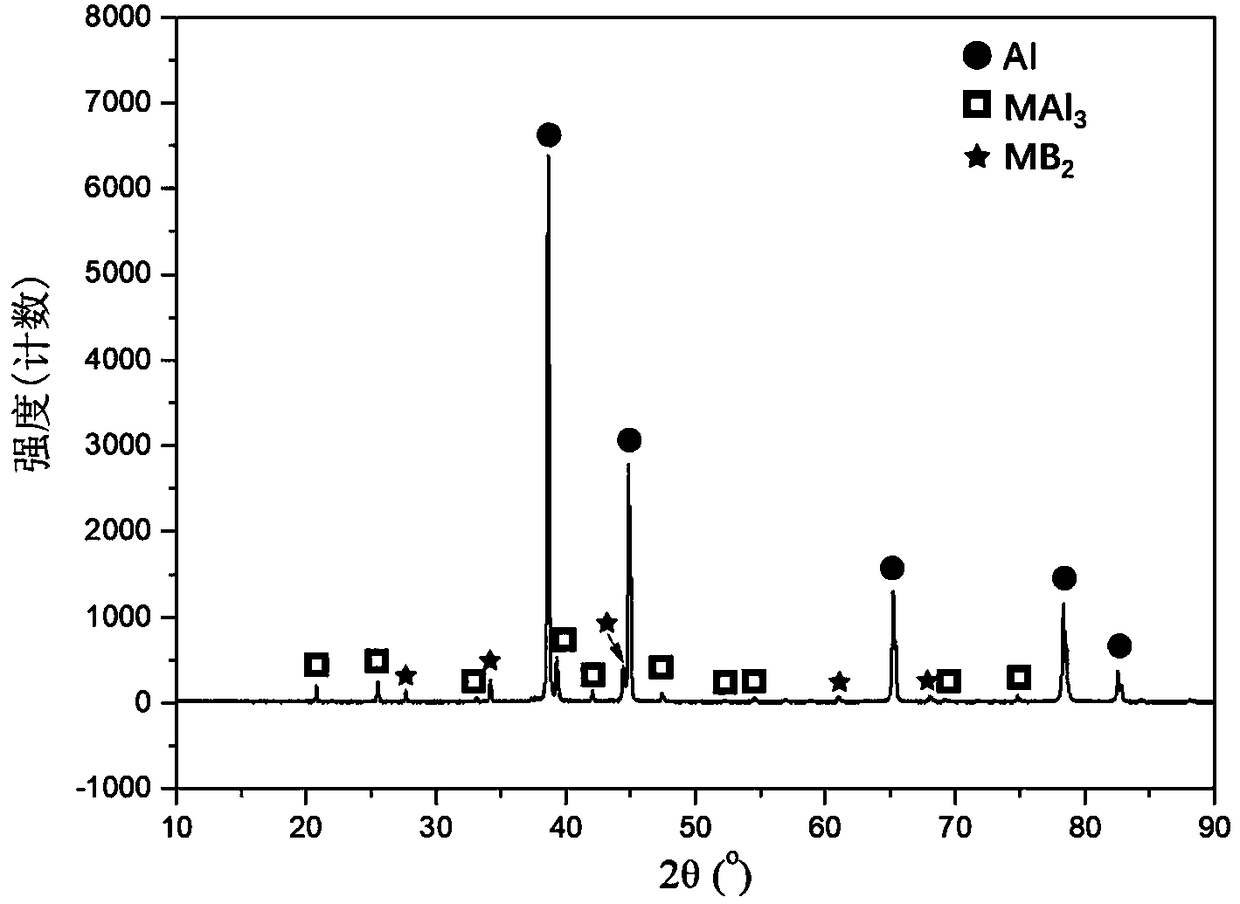

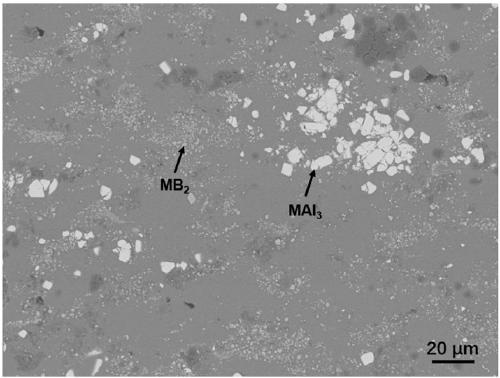

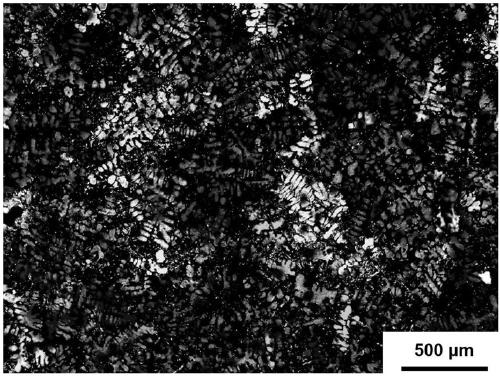

[0041] In this example, see Figure 1 ~ Figure 3 , a kind of preparation method of Al-M-B grain refiner for cast aluminum-silicon alloy, adopts fluorine salt method, and its steps are as follows:

[0042] a. Raw material preparation:

[0043] Using KBF 4 powder as B source material, using K 2 TiF 6 powder as the Ti source material, respectively weighed 98.7 grams of Al block, K 2 TiF 6 Powder 12.5g, Nb Powder 2.5g and KBF 4 14.0 grams of powder is used as a raw material, and the raw material that has been weighed already contains an additional weighing of K according to the standard that the yield of Ti, Nb and B is not less than 75%. 2 TiF 6 powder, Nb powder and KBF 4 The powder is used as a burning loss to supplement the raw material part;

[0044] b. Melting of Al-M-B alloy:

[0045] Mixing the raw materials weighed in the step a, melting the Al block at 800°C to obtain an aluminum melt; then adding K 2 TiF 6 powder, Nb powder, KBF 4 After the powder is mixed,...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

[0055] In this example, see Figure 7 ~ Figure 9 , a kind of preparation method of Al-M-B grain refiner for cast aluminum-silicon alloy, adopts fluorine salt method, and its steps are as follows:

[0056] a. Raw material preparation:

[0057] Using KBF 4 powder as B source material, using K 2 TiF 6 powder as the Ti source material, respectively weighed 99.4 grams of Al block, K 2 TiF 6 Powder 22.3g, Nb Powder 2.2g and KBF 4 19.4 grams of powder are used as raw materials, and the raw materials that have been weighed already contain additional weighing of K according to the standard that the yield of Ti, Nb and B is not less than 75%. 2 TiF 6 powder, Nb powder and KBF 4 The powder is used as a burning loss to supplement the raw material part;

[0058] b. This step is the same as in Embodiment 1.

[0059] Experimental test analysis:

[0060] Adopt X-ray diffraction, Rietveld refining t...

Embodiment 3

[0063] The aforementioned embodiment of this embodiment is basically the same as the embodiment, and the special features are:

[0064] In this example, see Figure 10 ~ Figure 13 , a kind of preparation method of Al-M-B grain refiner for cast aluminum-silicon alloy, adopts fluorine salt method, and its steps are as follows:

[0065] a. Raw material preparation:

[0066] Using KBF 4 powder as B source material, using K 2 TiF 6 powder as the Ti source material, respectively weighed 97.2 grams of Al block, K 2 TiF 6 Powder 11.0g, Nb Powder 4.3g and KBF 4 10.8 grams of powder are used as raw materials, and the raw materials that have been weighed already contain additional weighing of K according to the standard that the yield of Ti, Nb and B is not less than 75%. 2 TiF 6 powder, Nb powder and KBF 4 The powder is used as a burning loss to supplement the raw material part;

[0067] b. This step is the same as in Embodiment 1.

[0068] Experimental test analysis:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com