Method for compositely refining AZ31 magnesium alloy crystal particles by ultrasound field and refining agent

A refiner and magnesium alloy technology, applied in the field of magnesium alloy casting, can solve the problems of difficulty in adding, poor wettability between SiC ceramic particles and Mg matrix, and achieve the effects of low production cost, good refining effect and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0010] (1) Preheat the crucible and alloy material. When the crucible is heated to 500°C, add about 600 grams of Mg. After the Mg is melted, add the corresponding content of Al-10Mn and Zn, and sprinkle RJ-2 covering agent on the surface.

[0011] (2) Raise the temperature of the melt to 780° C., press a block refiner composed of SiC and Mg (0.5% by mass fraction) into the magnesium alloy melt with a bell jar, and keep it warm for 20 minutes.

[0012] (3) Stir the magnesium alloy melt to completely disperse the massive refiner, and continue to keep warm for 10 minutes.

[0013] (4) Refining with argon for 2 minutes, then cooling to 680°C and applying an ultrasonic field with an ultrasonic power of 350 watts, pouring after 2 minutes of treatment.

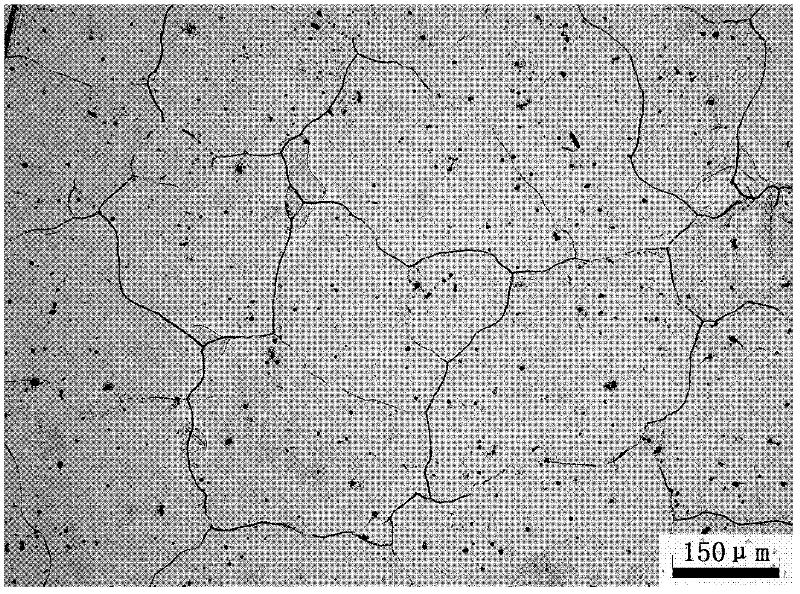

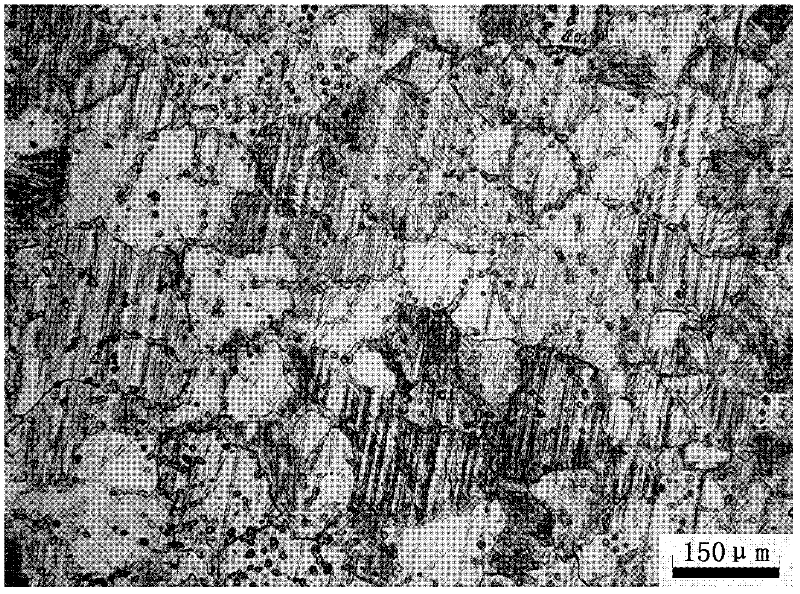

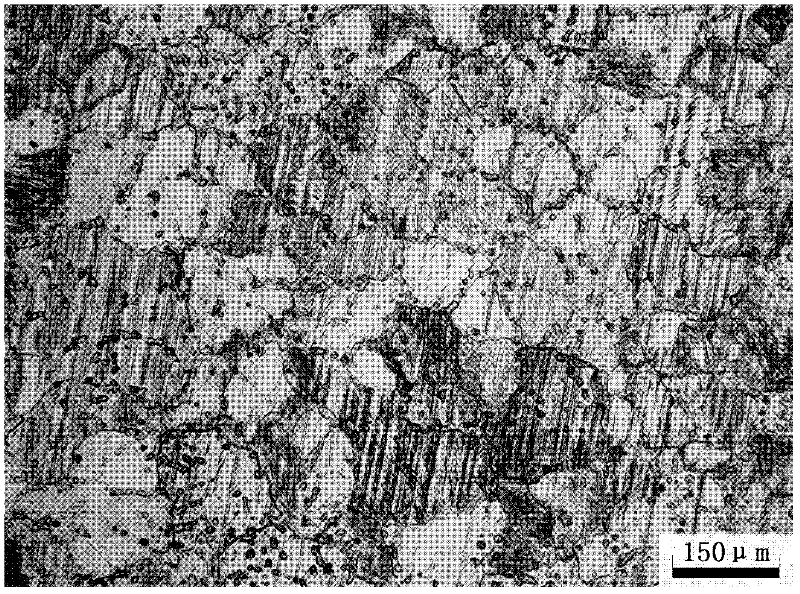

[0014] from figure 1 with figure 2 It can be seen from the compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com