Strong shearing and stirring aluminum alloy melt composite treatment device and technology

A technology of aluminum alloy melt and compound treatment, which is applied in the field of aluminum alloy smelting, and can solve problems such as coarse crystal grains of castings, incomplete treatment of atomic hydrogen and oxide inclusions, failure to achieve high-quality wheel hub mechanical properties and appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

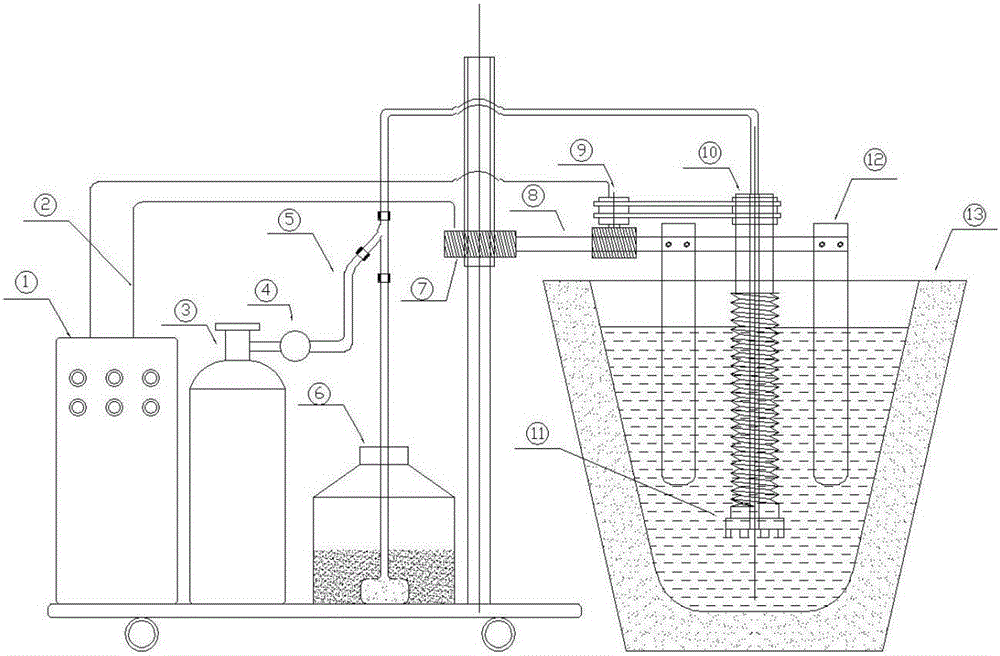

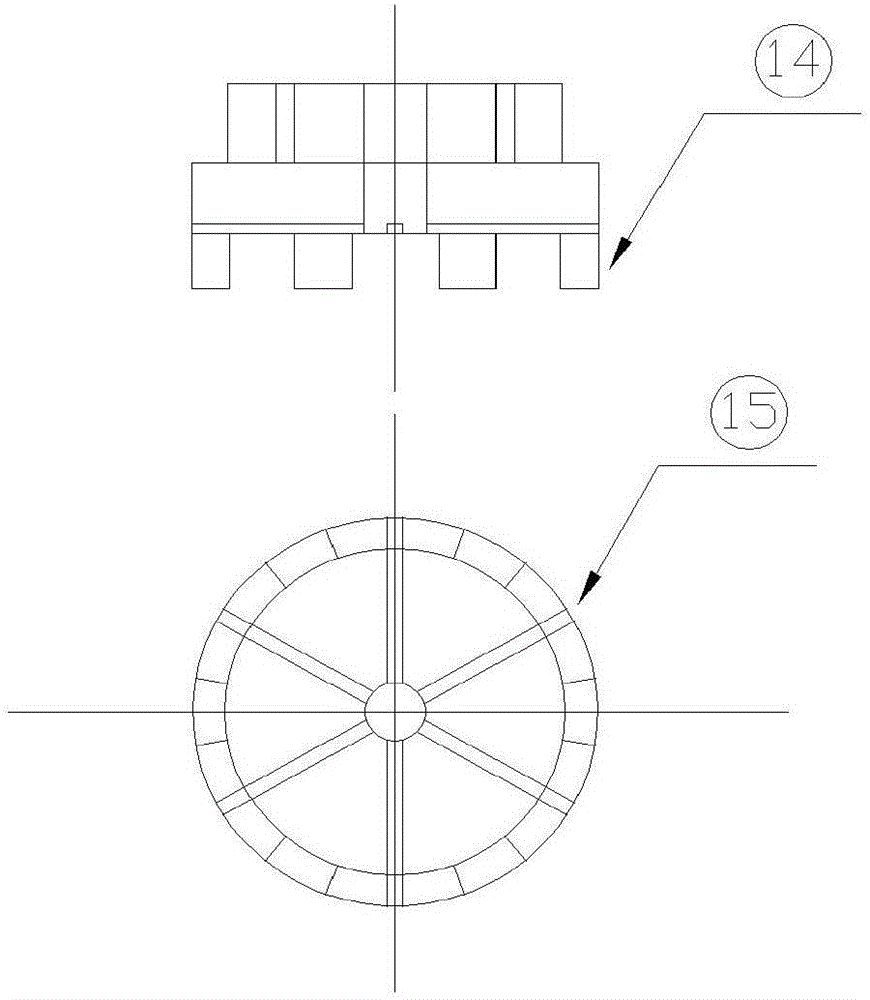

[0011] A strong shear and stirring aluminum alloy melt compound processing device, including a control cabinet 1, a wire 2, a gas storage bottle 3, a gas flow control valve 4, a gas pipe 5, a powder storage tank 6, a lifting system drive motor 7, and a support rod 8 , graphite rotor drive motor 9, graphite rotor 10, rotary nozzle 11, slag scraper 12, transfer bag 13; control cabinet 1 is connected with lifting system drive motor 7 and graphite rotor drive motor 9 through wire 2, and controls support rod 8 Up and down movement and the rotation of the graphite rotor drive motor 9; the graphite rotor drive motor 9 and the graphite rotor 10 are installed on the support rod 8, and the support rod 8 is connected with the lifting system drive motor 7; the graphite rotor drive motor 9 is connected to the graphite rotor 10 through a belt Connect and drive the graphite rotor to rotate to shear and stir the melt. There is a hole with a diameter of 10mm in the middle of the graphite rotor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com