Method for producing cryolite by wast liquid of vacuum residues in aluminium industry

A cryolite and waste liquid technology, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems of increased treatment cost, expensive treatment cost, waste of aluminum resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

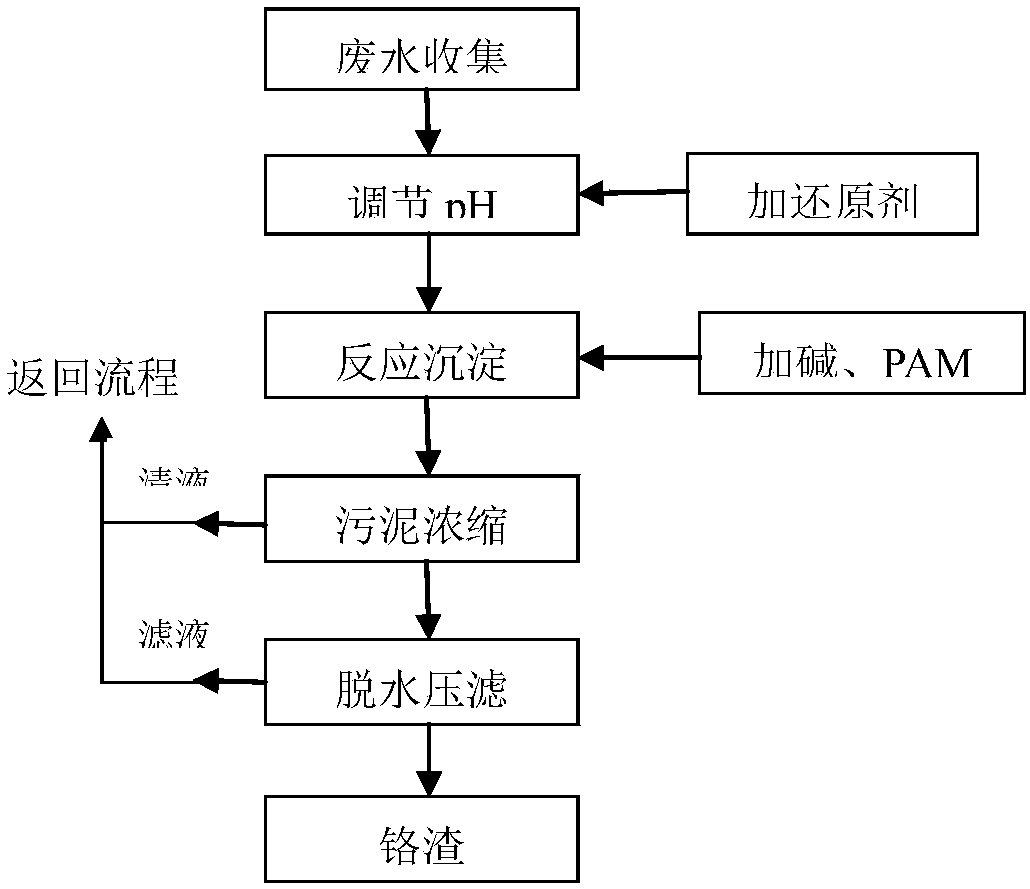

Problems solved by technology

Method used

Image

Examples

Embodiment 1

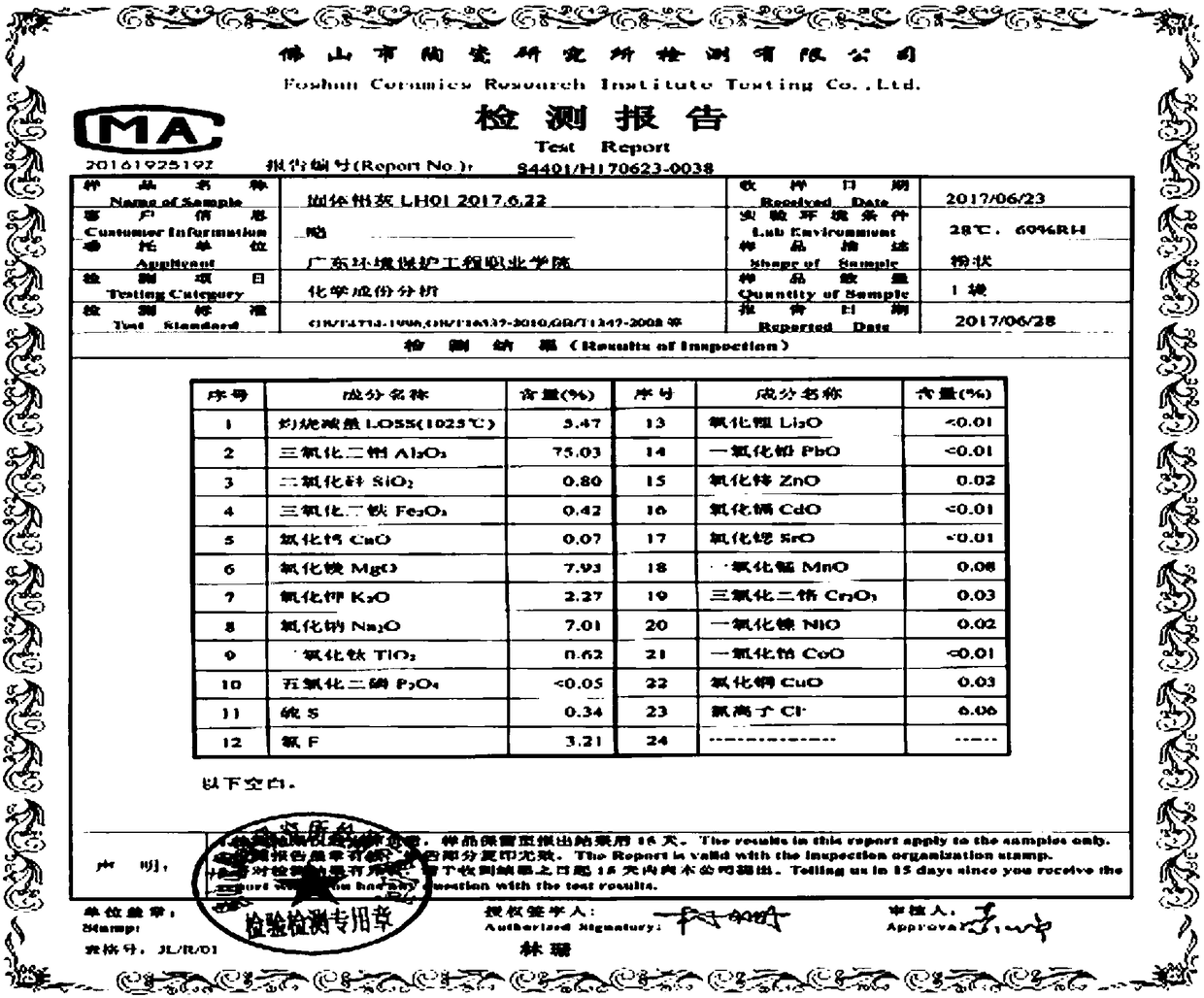

[0158] Get the mold waste liquid and detect, total alkali 5.995 equivalents, free alkali 3.060 equivalents, Al 3+ 2.935 equivalent; take hydrofluoric acid solution for detection, the content is 33.93 equivalent, and the density is 1.22g / m 3 .

[0159] Experiment with the following calculations:

[0160] According to HF (equivalent) / Al 3+ (equivalent)=2.30 times design, after fluoride ion and aluminum ion have reacted, also remaining part fluoride ion, produces sodium fluoride; At this moment, the hydrofluoric acid that needs to add is:

[0161] 2.3 × 2.935 = 6.751 equivalents, which is greater than 5.995 equivalents of the total alkali of potting mold waste liquid. After adding hydrofluoric acid, the reaction solution is acidic.

[0162] The specific operation steps of the method for producing cryolite from the waste liquid of the aluminum industry slag reduction of the present embodiment are:

[0163] (1), adding hydrofluoric acid to the mold waste liquid to synthesize cr...

Embodiment 2

[0170] Choose hydrofluoric acid, content 33.93 equivalent, density 1.22g / m 3 , the experiment is calculated as follows:

[0171] Take 10ml of hydrofluoric acid, titrate with the oxidation line alkali etching waste liquid containing sodium metaaluminate and sodium hydroxide, consume 50ml of waste liquid, it is neutral at this time, need to add excess hydrofluoric acid, produce ice crystals under acidic conditions Stone, get hydrofluoric acid addition to be 1.15 times of reacting to neutrality:

[0172] According to the titration results, when 1000ml of waste liquid is added to 200ml of hydrofluoric acid, the reaction solution is neutral, and 1.16 times of hydrofluoric acid is actually added:

[0173] 200×1.16=232ml,

[0174] After the addition of hydrofluoric acid, the reaction solution is acidic and reaches the end point of the cryolite reaction.

[0175] The specific operation steps are:

[0176] a. Add hydrofluoric acid to the waste liquid to synthesize cryolite. Take 1...

Embodiment 3

[0189] Choose hydrofluoric acid, content 33.93 equivalent, density 1.22g / m 3 , the experiment is calculated as follows:

[0190] Take 10ml of hydrofluoric acid, titrate with the alkaline solution of aluminum ash containing sodium metaaluminate and sodium hydroxide, and consume 49ml of waste liquid, which is neutral at this time, and excess hydrofluoric acid needs to be added to produce ice crystals under acidic conditions Stone, get hydrofluoric acid addition to be 1.15 times of reacting to neutrality:

[0191] According to the titration results, when 1000ml of waste liquid is added to 204ml of hydrofluoric acid, the reaction solution is neutral, and 1.18 times of hydrofluoric acid is actually added:

[0192] 204×1.18=240ml,

[0193] After the addition of hydrofluoric acid, the reaction solution is acidic and reaches the end point of the cryolite reaction.

[0194] The specific operation steps are:

[0195] a. Add hydrofluoric acid to the waste liquid to synthesize cryolit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com