Safety valve specially for aluminium industry

A safety and aluminum technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of shortened equipment life, pipeline and equipment scouring and wear, safety valve frequency jump, etc., to ensure safe and reliable operation, improve Action performance, ensuring the effect of normal action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

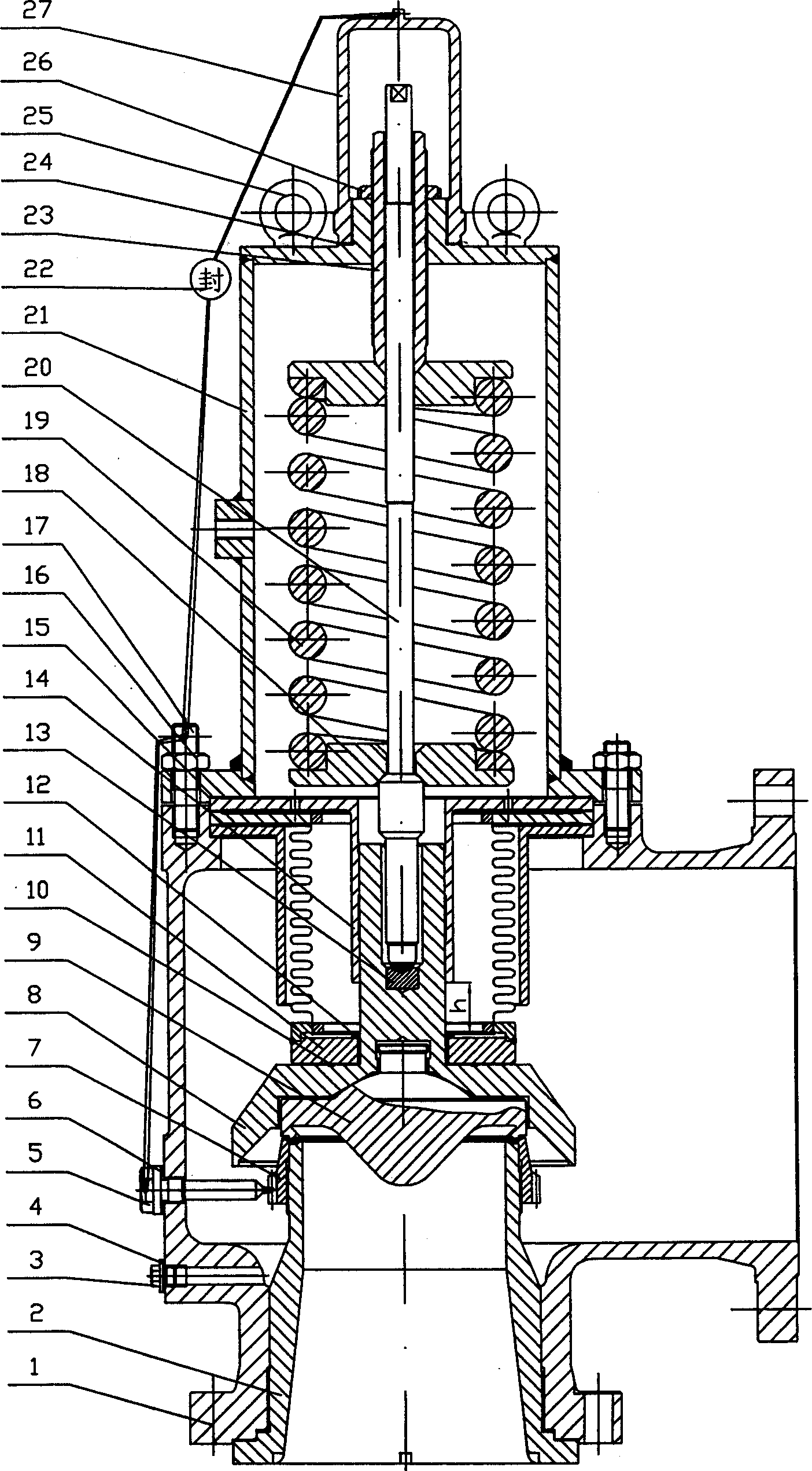

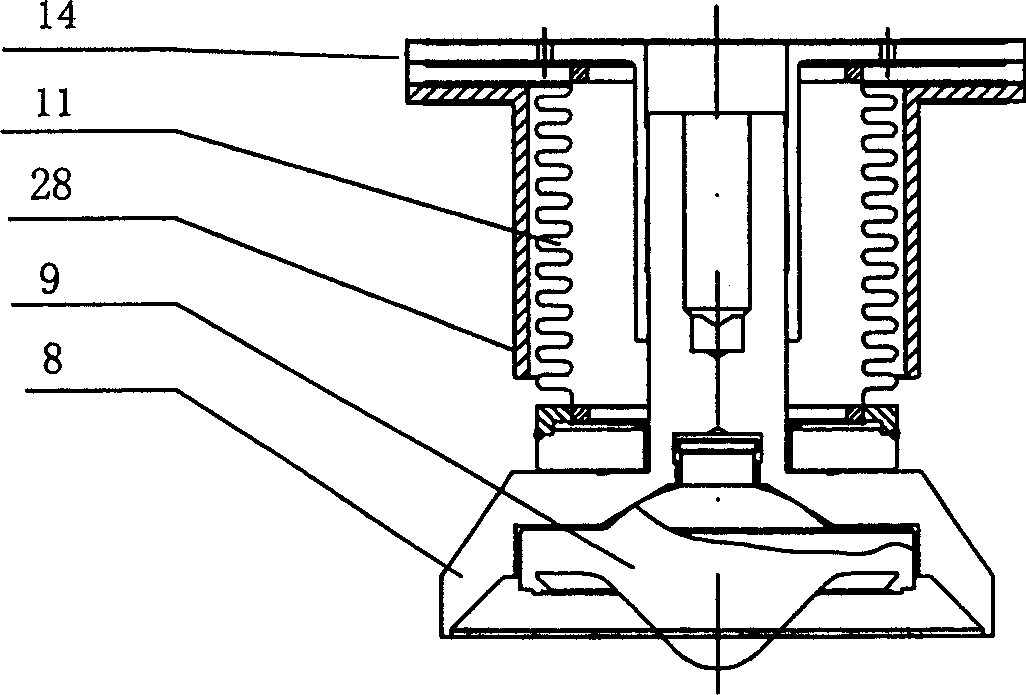

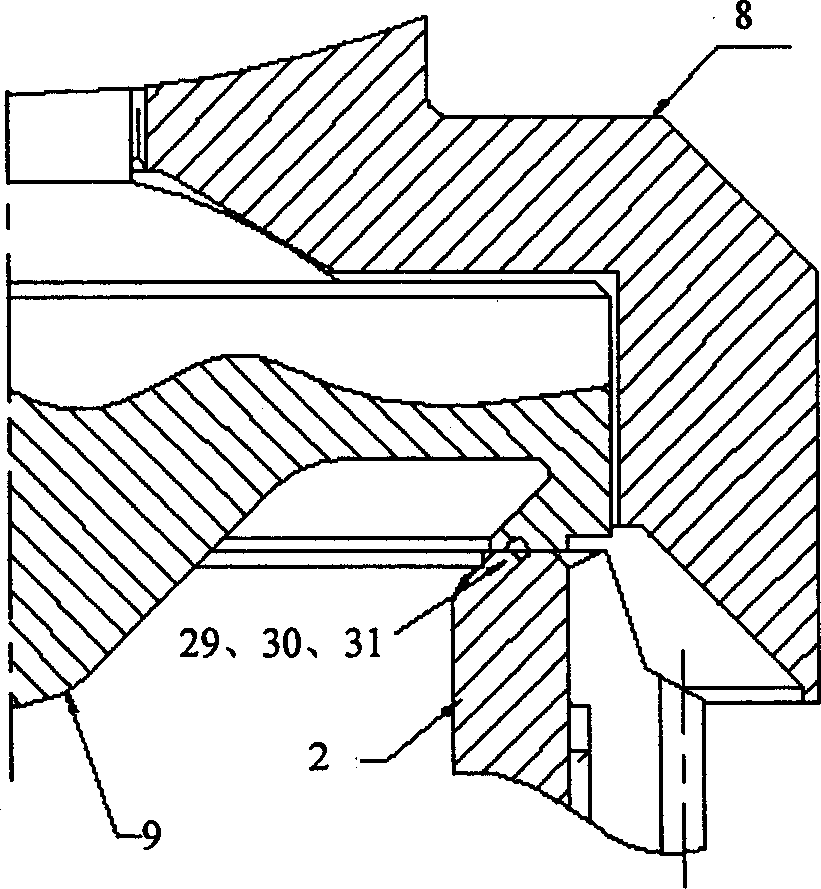

[0018] According to the accompanying drawings, the principle of action of the product of the present invention and its structure and characteristics are as follows.

[0019] Principle of action:

[0020] When the protected pressure-bearing system is in normal working condition, the spring force acting on the disc is balanced with the force of the medium and the sealing force between the disc and the valve seat, and the safety valve is in a sealed state. As the system pressure gradually increases, the sealing force between the valve disc and the valve seat decreases accordingly. When the system pressure rises to the specified value, the sealing force between the valve disc and the valve seat decreases to zero, and the valve disc immediately Open, the safety valve begins to discharge the medium. The system pressure continues to rise, and when it reaches a certain value, the disc is raised to the specified height, and the safety valve is fully open. At this time, the safety valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com