High-electric-conductive anode assembly effectively solving inward-bending deformation

An anode device and high conductivity technology, which is applied in the field of anode conductive devices in the electrolytic aluminum industry, can solve problems such as aluminum core melting leakage, structural heat resistance deformation, poor service life, etc., and achieve improved strength, high conductivity, and reduced energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

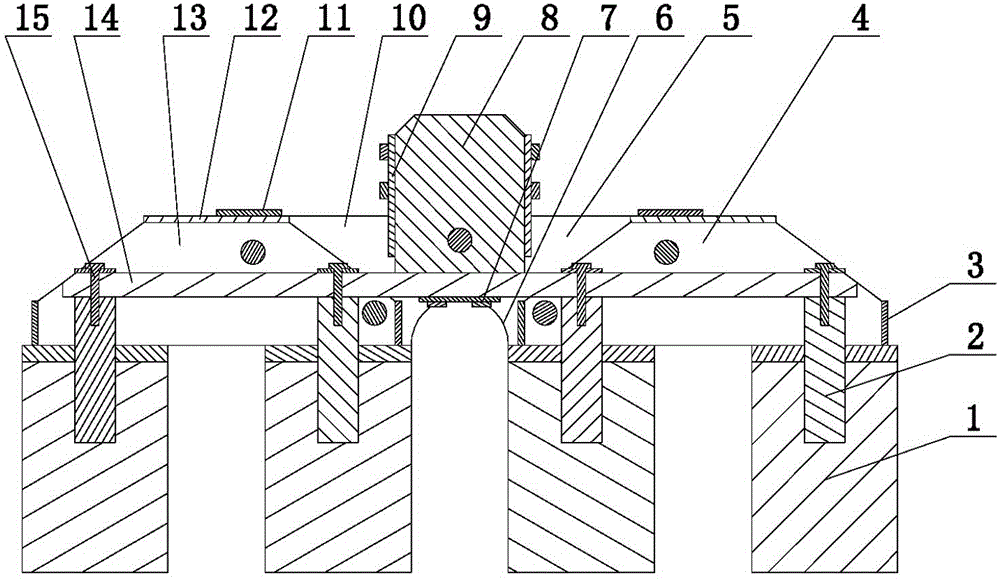

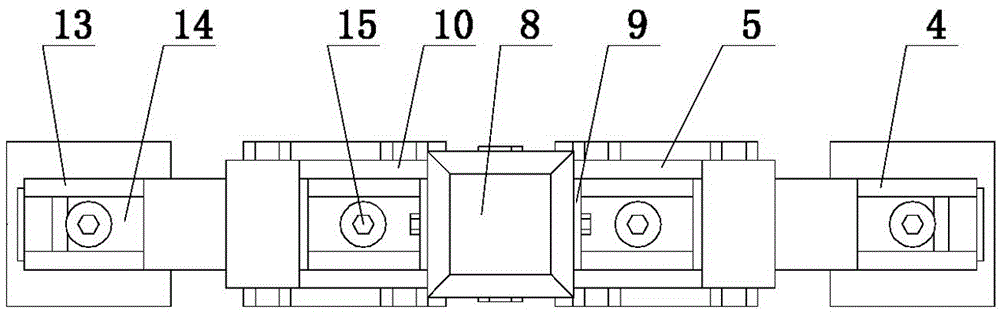

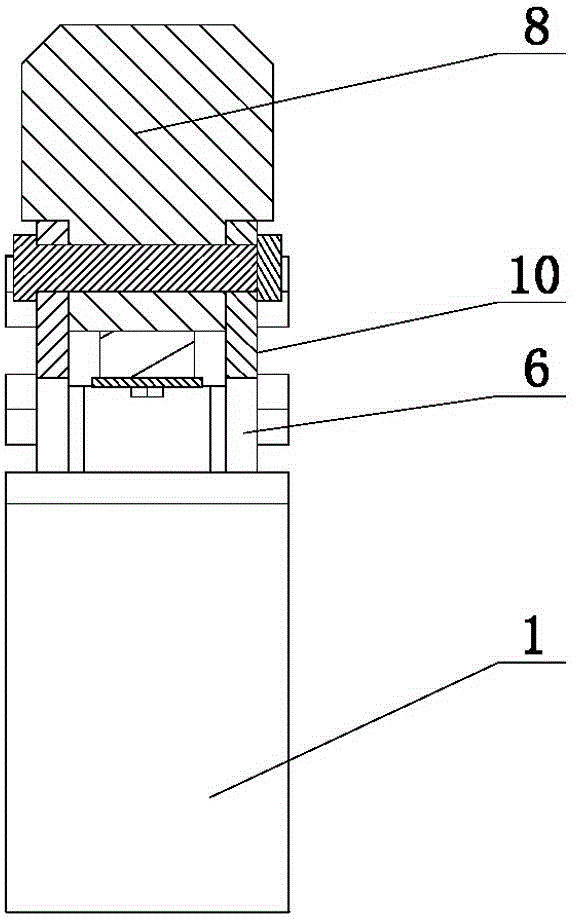

[0028] The present invention includes a supporting beam 5, which is characterized in that: the supporting beam 5 includes a first U-shaped steel plate 10, an aluminum boss 8 is arranged in the middle of the first U-shaped steel plate 10 through a bolt assembly, and the upper end of the aluminum boss 8 is formed by a supporting beam. 5 protrudes above; the two ends of the first U-shaped steel plate 10 are provided with a movable beam 4, and the movable beam 4 includes a second U-shaped steel plate 13 that is socketed with the end of the first U-shaped steel plate 10, and the second The U-shaped steel plate 13 is connected with the first U-shaped steel plate 10 through the bolt assembly in the elongated hole 16 on the first U-shaped steel plate 10; the two ends of the bottom of the first U-shaped steel plate 10 are respectively provided with steel claw heads 1; The end of the second U-shaped steel plate 13 that is not connected to the first U-shaped steel plate 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com