Ultrahigh strength mining anchoring assembly and application

An ultra-high-strength, mining technology, used in mining equipment, bolt installation, earthwork drilling, etc., can solve the problems of poor bolt support and insufficient strength, and achieve good supporting effect, convenient installation, and improved performance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

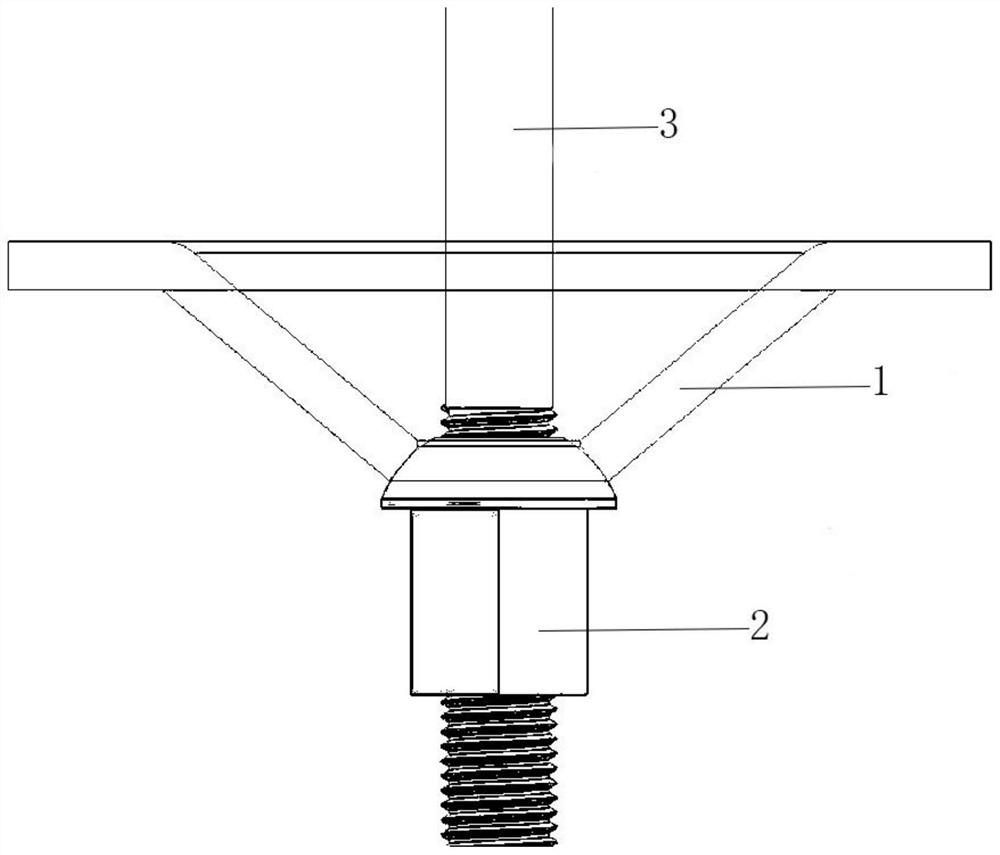

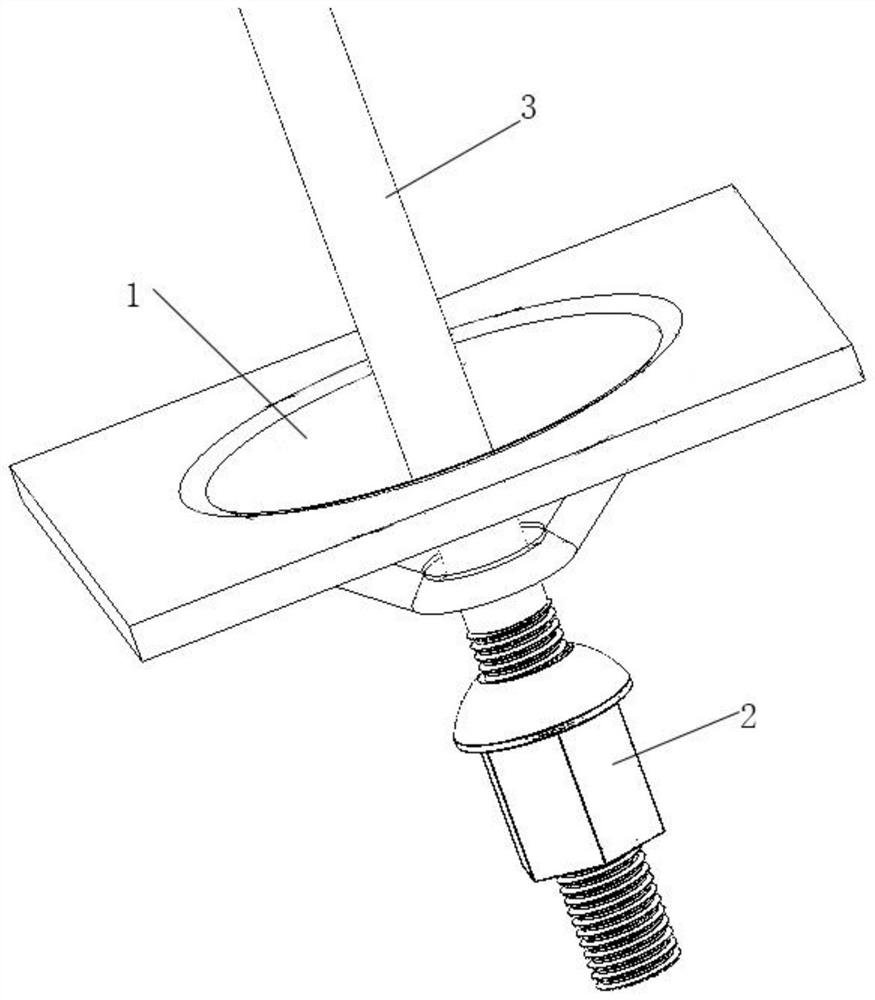

[0038] In this embodiment, the yield strength of the anchor rod 3 is 600Mpa to 800Mpa, and the section elongation is greater than 15%. According to the mass percentage, the material used for the anchor rod is composed of the following components: 0.2% carbon, 1% silicon, 3% manganese, 0.05% vanadium, 0.02% titanium, 0.01% niobium, 0.04% aluminum, and the rest are iron and trace impurity elements, The microstructure of the material is a low-carbon vanadium-niobium-titanium microalloyed bainite / martensite multiphase structure.

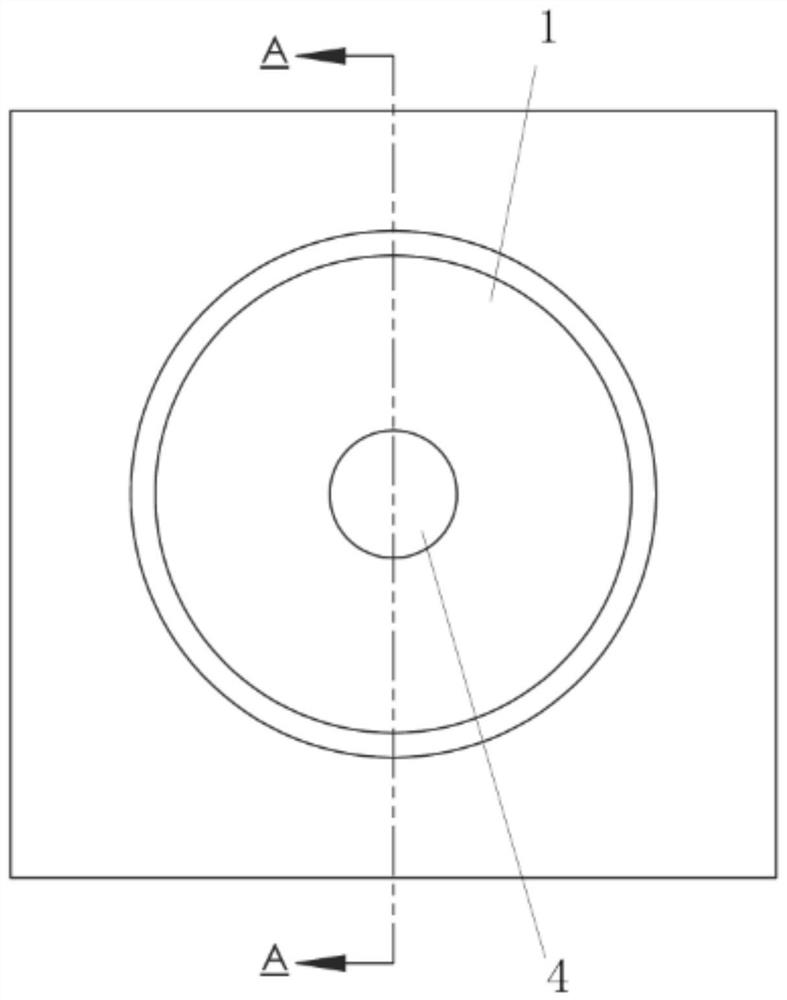

[0039] The material of the anchor tray 1 is Q235 steel, and the thickness of the tray is 9mm.

Embodiment 2

[0041] In this embodiment, the yield strength of the anchor rod 3 is 800Mpa to 1000Mpa, and the section elongation is greater than 15%. According to the mass percentage, the material used for the anchor rod is composed of the following components: 0.22% carbon, 0.5% silicon, 2% manganese, 0.09% vanadium, 0.01% titanium, 0.03% niobium, 0.02% aluminum, and the rest are iron and trace impurity elements, The microstructure of the material is a low-carbon vanadium-niobium-titanium microalloyed bainite / martensite multiphase structure.

[0042] The material of the anchor tray 1 is Q235 steel, and the thickness of the tray is 10mm.

Embodiment 3

[0044] In this embodiment, the yield strength of the anchor rod 3 is 1000Mpa to 1200Mpa, and the section elongation is greater than 15%. According to mass percentage, carbon 0.2%, silicon 0.6%, manganese 2.5%, vanadium 0.03%, titanium 0.04%, niobium 0.05%, aluminum 0.01%, the rest is iron and trace impurity elements, the microstructure of this material is low carbon vanadium niobium Titanium microalloyed bainite / martensite multiphase structure.

[0045] The material of the anchor tray 1 is Q345 steel, and the thickness of the tray is 10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com