A Stiffness Testing Device for Flexible Disk of Automatic Transmission

A testing device and flexible disc technology, which is applied in the direction of elastic testing, machine/structural component testing, measuring devices, etc., can solve problems such as bending and deformation, and achieve the effects of easy processing and assembly, convenient operation, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

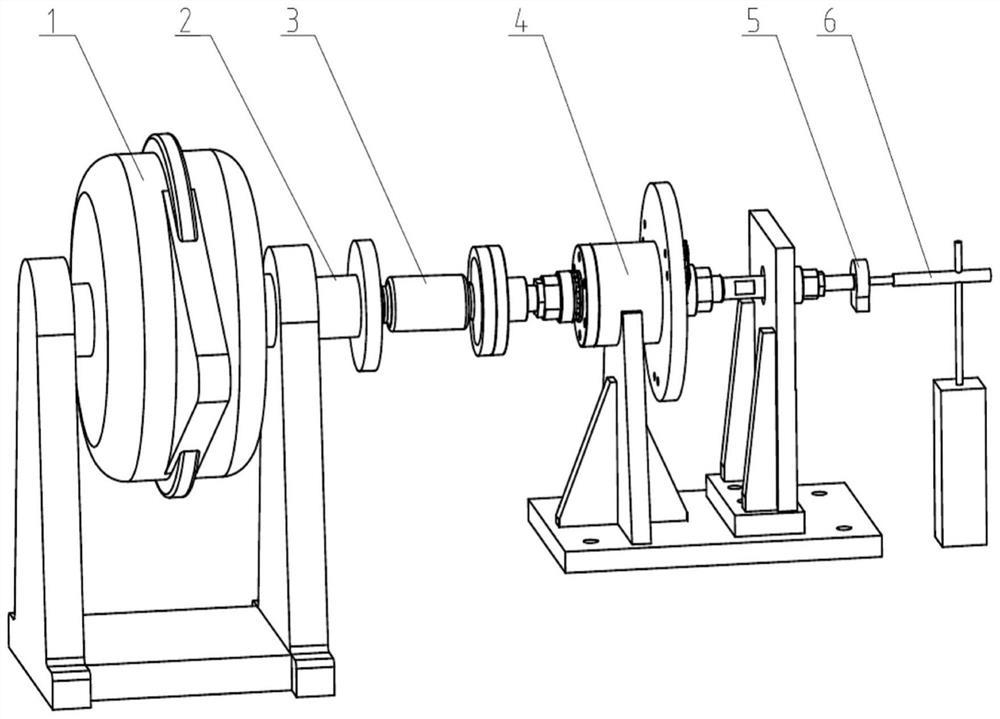

[0024] figure 1 The present invention provides a test device for testing the torsional stiffness of a flexible disc. Such as figure 1 As shown, the device includes: a torsional loader 1 , a torque sensor 2 , a transmission shaft 3 , a torsional rigidity clamping device 4 , an angle sensor 5 and a displacement sensor 6 . The torsional loader 1 is connected with the torque sensor 2, which can provide the torque load required for the test; the torque sensor 2 is connected with the flexible disk clamping device through the transmission shaft 3, and can measure the torque load applied by the torsional loader 1 in real time ;

[0025] The angle sensor 5 and the displacement sensor 6 are arranged at the end of the torsional stiffness clamping device 4 for measuring the rotation angle and axial displacement generated during the test;

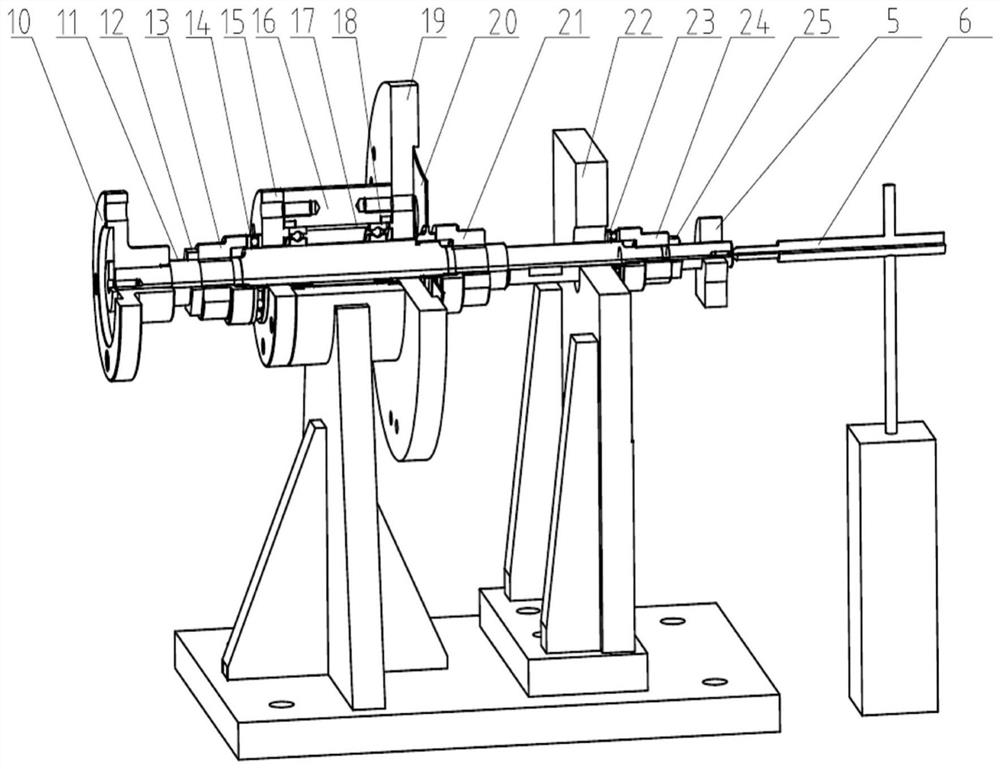

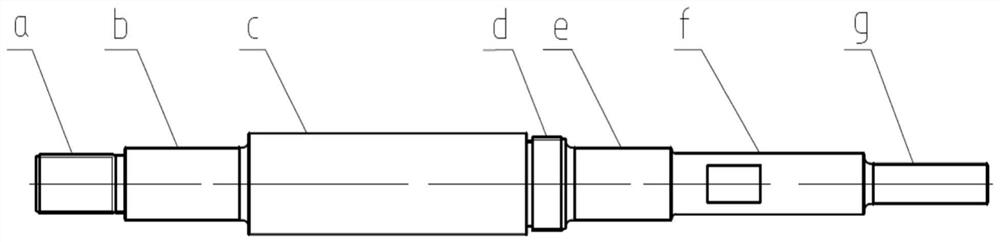

[0026] Such as figure 2As shown, the torsional stiffness clamping device 4 includes a flange 10, a shaft 11, a first lock nut 12, a positive loadi...

Embodiment 2

[0033] Figure 4 The present invention provides a test device for testing the axial stiffness of a flexible disc. Such as Figure 4 As shown, the device includes an axial loader 7 , a force sensor 8 , an axial stiffness clamping device 9 and a displacement sensor 6 . The axial loader 7 is a rack and pinion structure, which is threadedly connected with the force sensor 8 to apply an axial load; one end of the force sensor 8 is connected to the axial loader 7, and the other end is clamped with the axial rigidity The device 9 is connected by screwing.

[0034] Such as Figure 5 As shown, the axial stiffness clamping device 9 includes a displacement shaft 11, an end cover 15, a bracket 16, a mounting plate 19, a flexible disk 20, a flexible disk fastening nut 21, a transition flange 26 and a linear motion bearing 27; Except for the transition flange 26 and the linear motion bearing 27, the rest of the parts are shared with the torsional rigidity clamping device 4. The left en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com