Method for delithiation, purification and recovery of lithium from aluminum electrolyte

An aluminum electrolyte, lithium recovery technology, applied in the improvement of process efficiency, lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., to improve labor efficiency, reduce production costs, and reduce production costs. Effects of Toxic and Hazardous Substances Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

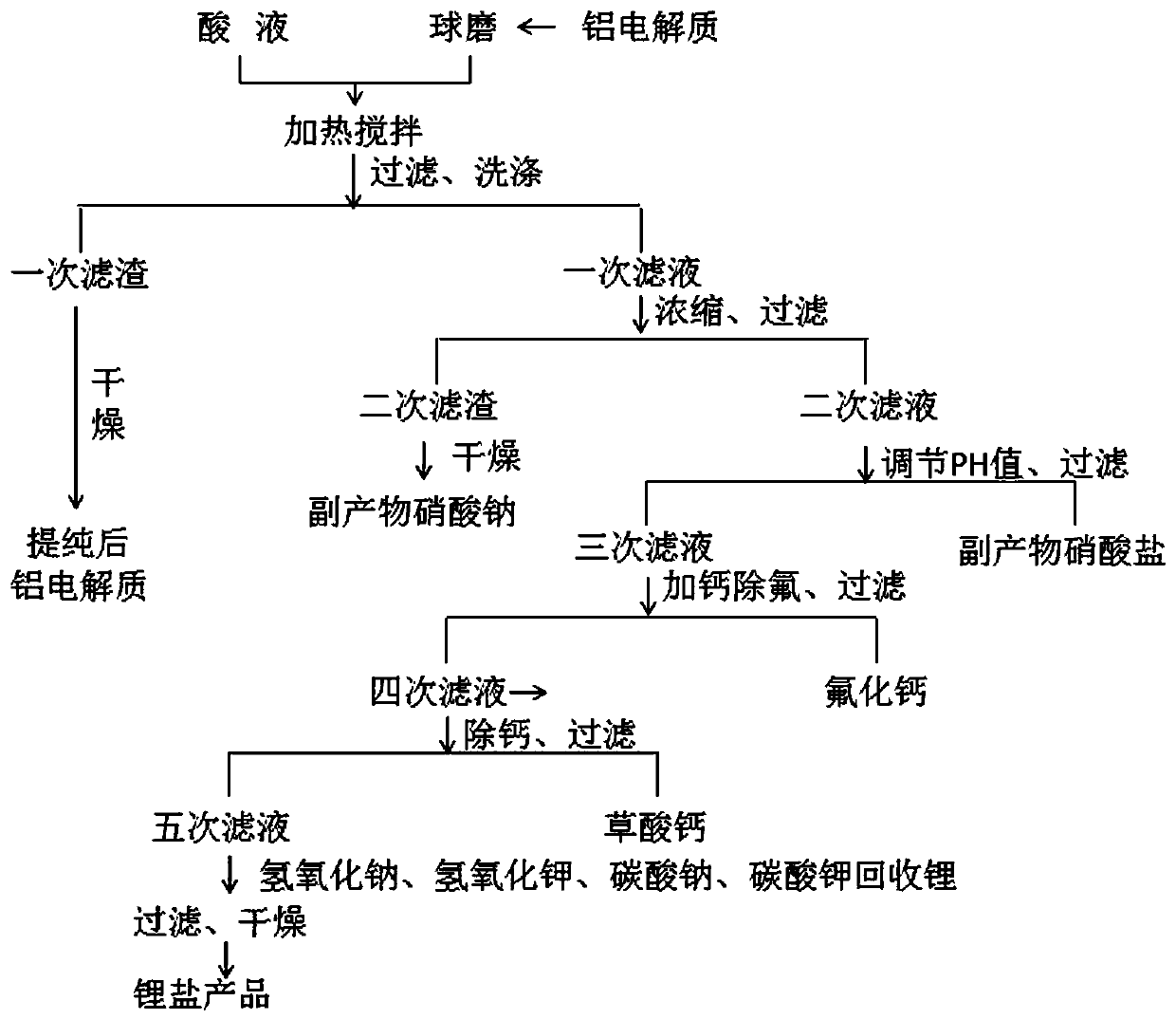

[0038] The method for delithiation, purification and lithium recovery of the aluminum electrolyte of this embodiment, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0039] Step 1: Delithiation and purification of aluminum electrolyte

[0040] (1) The aluminum electrolyte containing lithium is ball milled and the main component of the aluminum electrolyte is cryolite Na 3 AlF 6 , calcium fluoride CaF 2 , lithium fluoride LiF, etc., wherein the content of lithium fluoride LiF is 6.5%, passing through a 50-200 mesh sieve;

[0041] (2) Weigh 30g of 100-mesh aluminum electrolyte containing 6.5% lithium fluoride LiF and slowly add it to 110mL of nitric acid with a concentration of 2.5mol / L, and stir at 70°C for 5h;

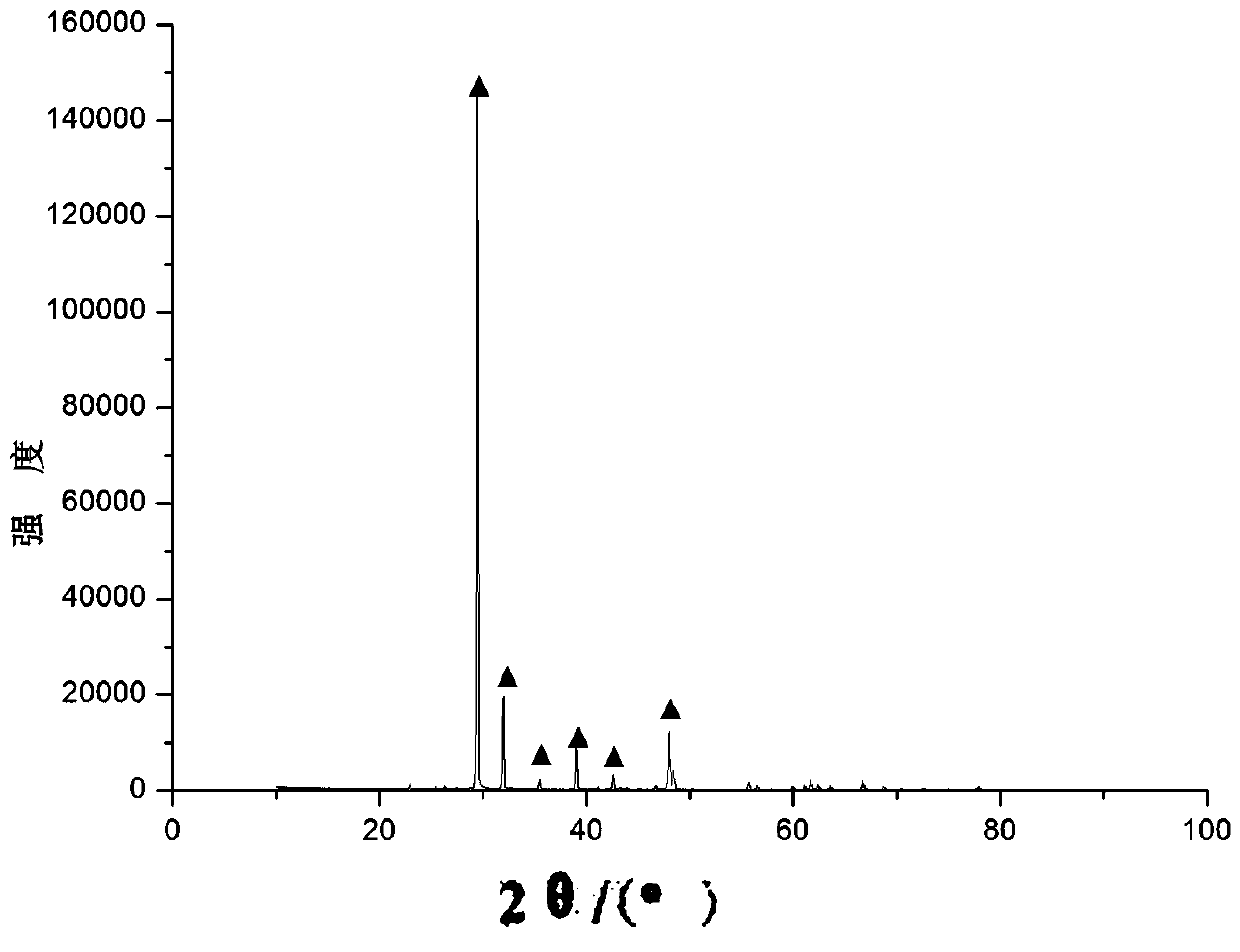

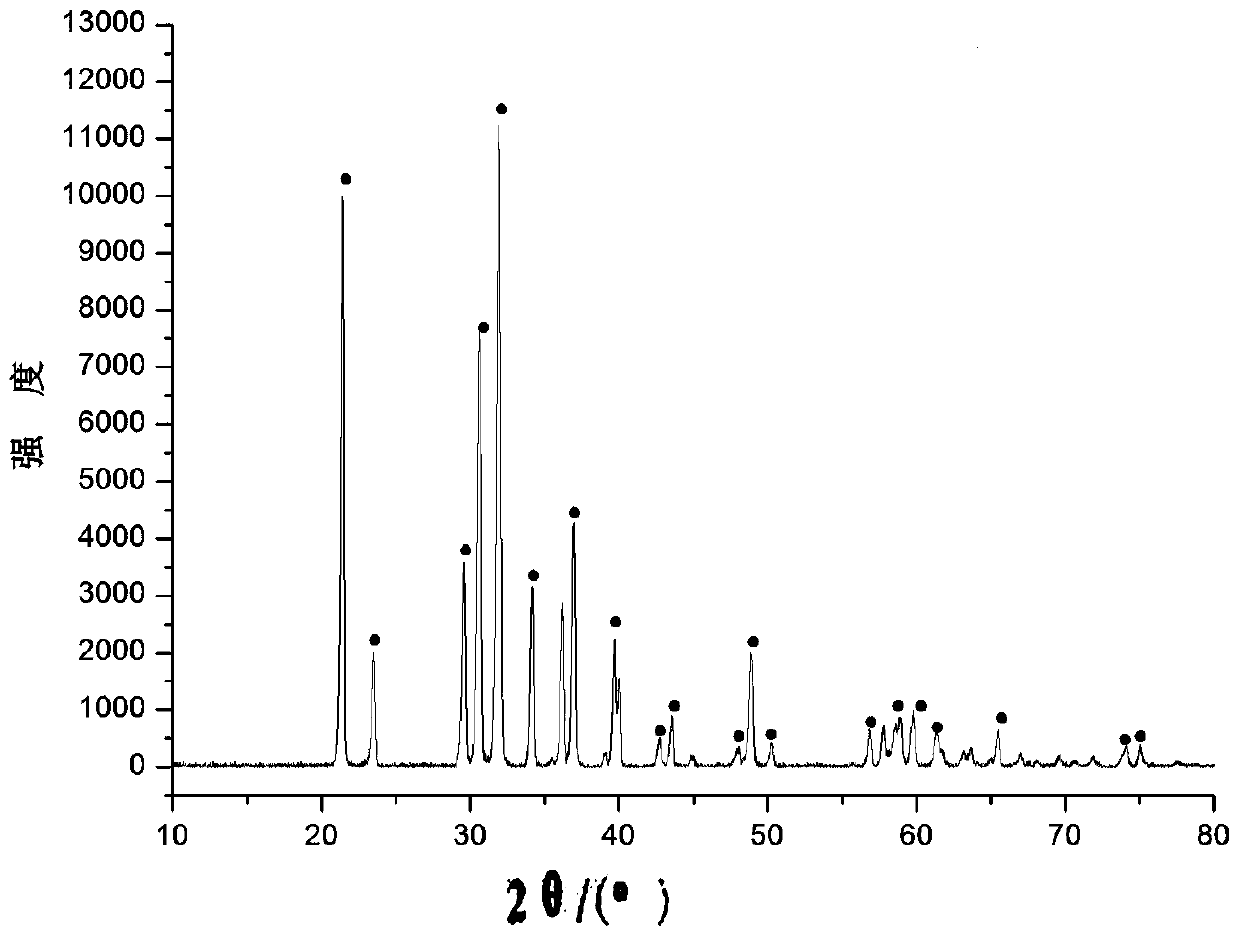

[0042] (3) Cool the mixed solution after the reaction to room temperature under natural conditions, filter and wash the filter residue several times until the pH value of the final washing liquid is 7, and obtain th...

Embodiment 2

[0049] The method for delithiation, purification and lithium recovery of the aluminum electrolyte of this embodiment, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0050] Step 1: Delithiation and purification of aluminum electrolyte

[0051] (1) The aluminum electrolyte containing lithium is ball milled and the main component of the aluminum electrolyte is cryolite Na 3 AlF 6 , calcium fluoride CaF 2 , lithium fluoride LiF, etc., wherein the content of lithium fluoride LiF is 8.5%, passing through a 50-200 mesh sieve;

[0052] (2) Weigh 100g of 200-mesh aluminum electrolyte containing 8.5% lithium fluoride LiF and slowly add it to 1000mL of nitric acid with a concentration of 7mol / L, and stir at 115°C for 3h;

[0053] (3) After the reaction, the mixed solution was naturally cooled to room temperature, filtered, and the filter residue was washed several times until the pH of the final washing liquid was 7, and the primary ...

Embodiment 3

[0060] The method for delithiation, purification and lithium recovery of the aluminum electrolyte of this embodiment, the process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0061] Step 1: Delithiation and purification of aluminum electrolyte

[0062] (1) The aluminum electrolyte containing lithium is ball-milled and crushed. The main component of the aluminum electrolyte is cryolite Na 3 AlF 6 , calcium fluoride CaF 2 , lithium fluoride LiF, etc., wherein the content of lithium fluoride LiF is 7.5%, passing through a 50-200 mesh sieve;

[0063] (2) Weigh 20g of 50-mesh aluminum electrolyte containing 7.5% lithium fluoride LiF and slowly add it to 400mL of nitric acid with a concentration of 12mol / L, and stir at 70°C for 9h;

[0064] (3) Cool the mixed liquid after the reaction to room temperature naturally, filter and wash the filter residue several times until the pH value of the final washing liquid is 7, and obtain the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com