Furnace, dispatching method and device for aluminum continuous cast-rolling production

A scheduling method, casting and rolling technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the difficulty of considering quality, production efficiency and customer satisfaction at the same time, and it is difficult for technicians to consider production information, electrolytic cells as a whole. and the large amount of contract data, to achieve the effect of reasonable production operation plan, optimization of furnace group and furnace scheduling, and improvement of operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

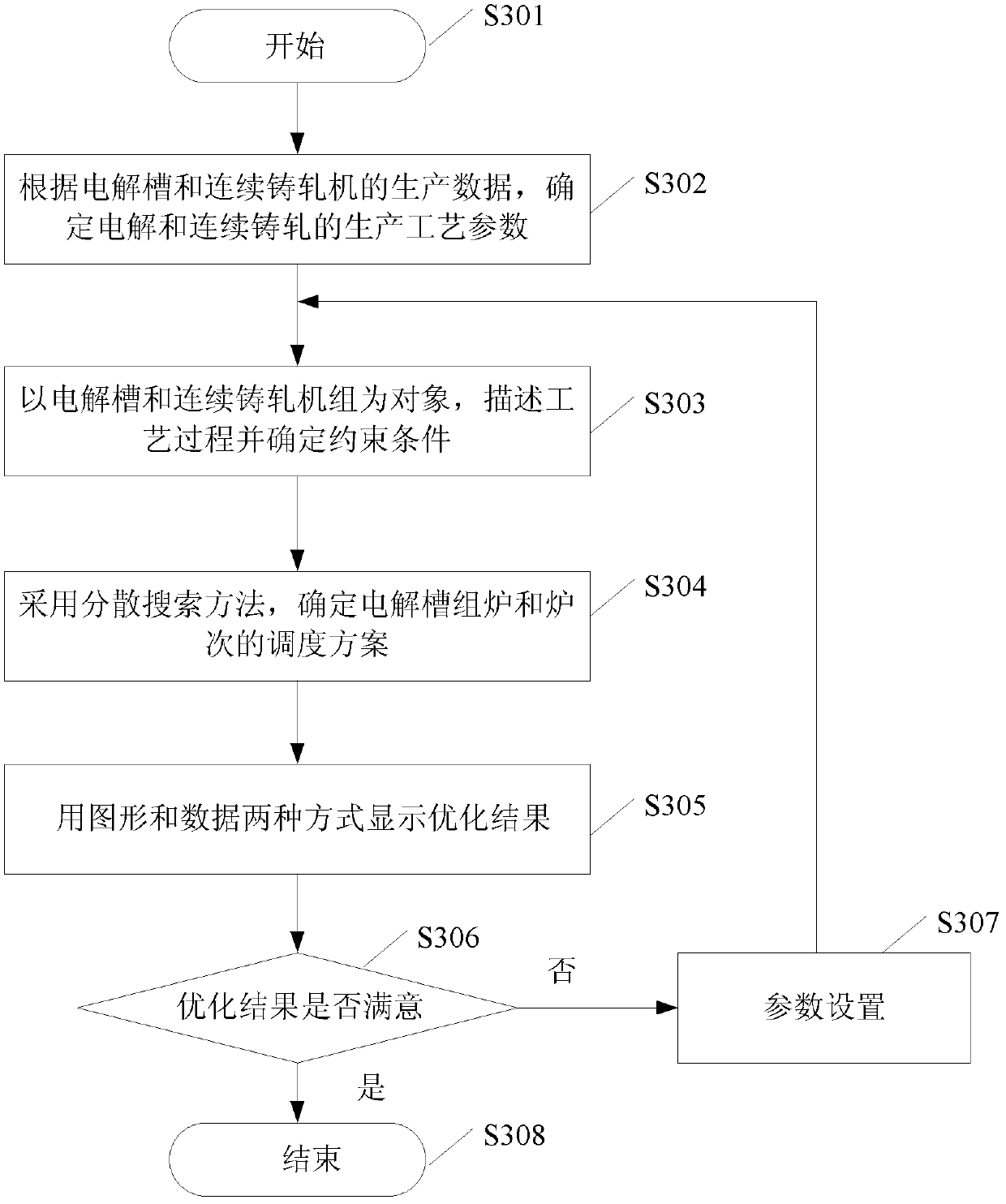

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

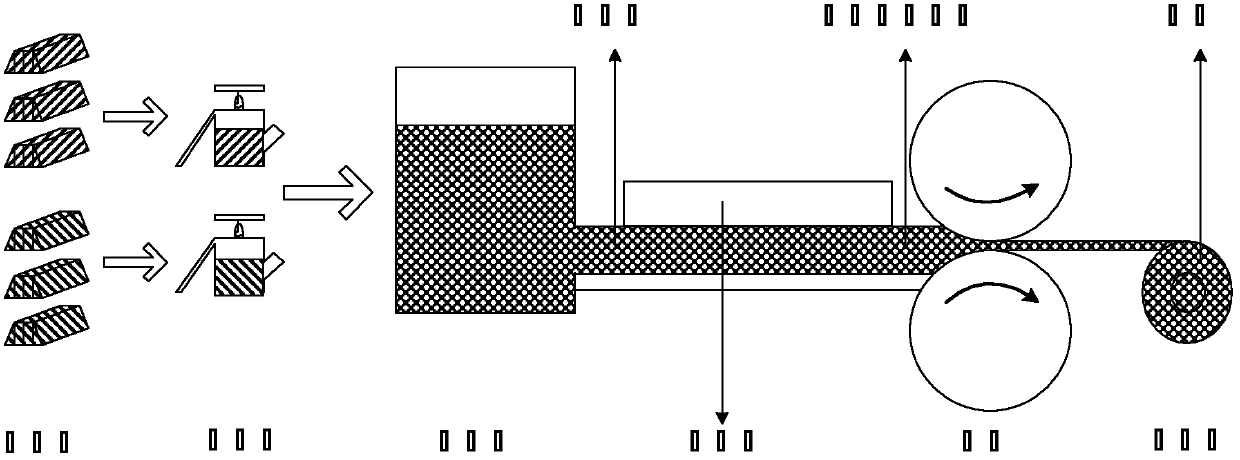

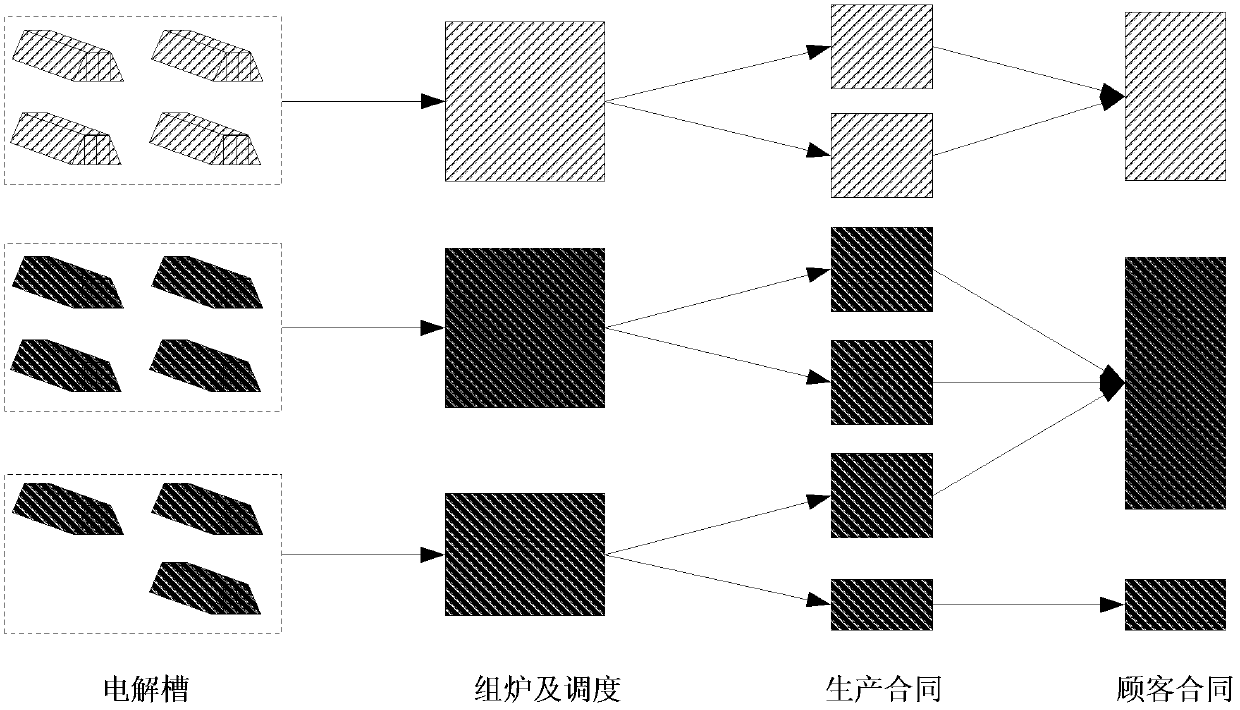

[0029] image 3 It is a flow chart of furnace grouping and dispatching method for aluminum continuous casting and rolling production according to an embodiment of the present invention, and the process starts at step 301 . Then, in step 302, from the EPR system (i.e. enterprise database) used to store production, material and equipment information in the aluminum plant, the production data of the electrolytic cell and the continuous casting and rolling mill are called, and the production data includes: electrolytic cell i (For example, the number of electrolyzers is 18 groups, respectively 18, 24, 30, 36, 42, 48, 54, 60, 66, 72, 78, 84, 90, 96, 102, 108, 114, 120) The purity of aluminum liquid is a i (For example, randomly generated according to uniform distribution according to the range of [99.53%, 99.99%]), heat number k (for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com