Low-emission high-strength red-mud concrete, and industrial production method and application thereof

A high-strength, concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as groundwater pollution, land alkalization, and health hazards, and achieve high polymerization degree, low cost, and high use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

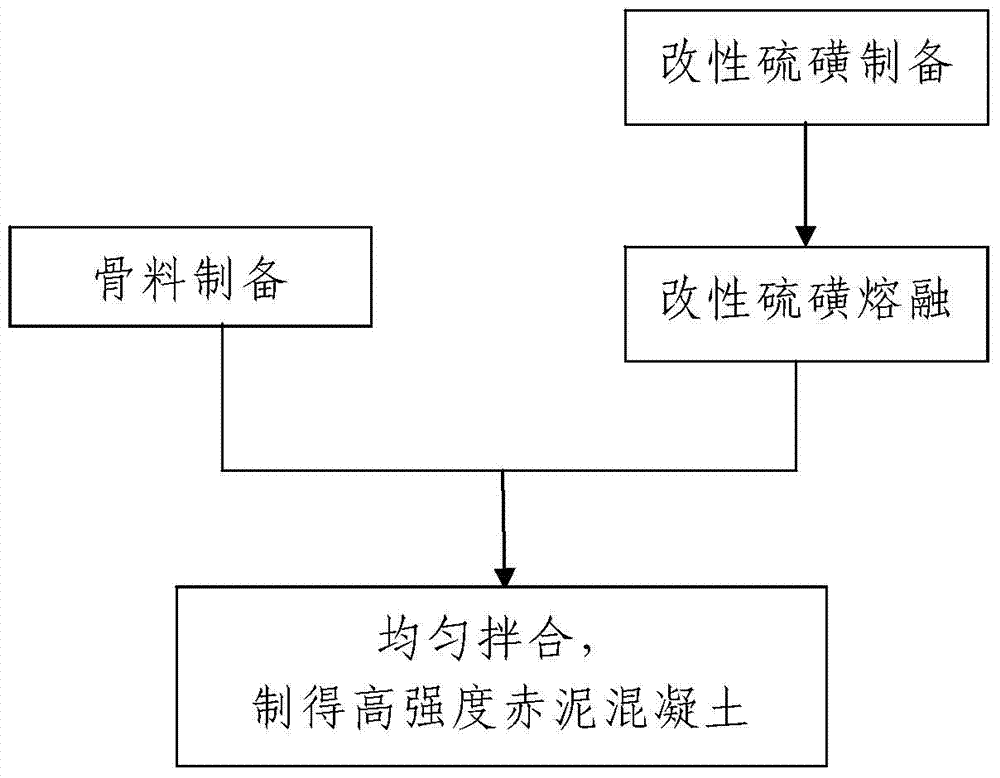

Method used

Image

Examples

Embodiment 1

[0038] In this example, the prepared high-strength red mud concrete is uniformly mixed with modified sulfur and red mud particles. The composition of the high-strength red mud concrete is by weight: 40% modified sulfur, 60% red mud particles . The particle size of the red mud particles is ≤0.1mm.

[0039] The preparation process of described modified sulfur is as follows:

[0040] Step 1, preparation of sulfur mixed solution: mixing sulfur and ferrous chloride aqueous solution to obtain sulfur mixed solution; the weight ratio of sulfur in the sulfur mixed solution to ferrous chloride in the described ferrous chloride aqueous solution is 500: 20.

[0041] Step II, sulfur melting: using heating equipment and under constant temperature conditions, heat the sulfur mixture described in step I until the sulfur is heated to a molten state.

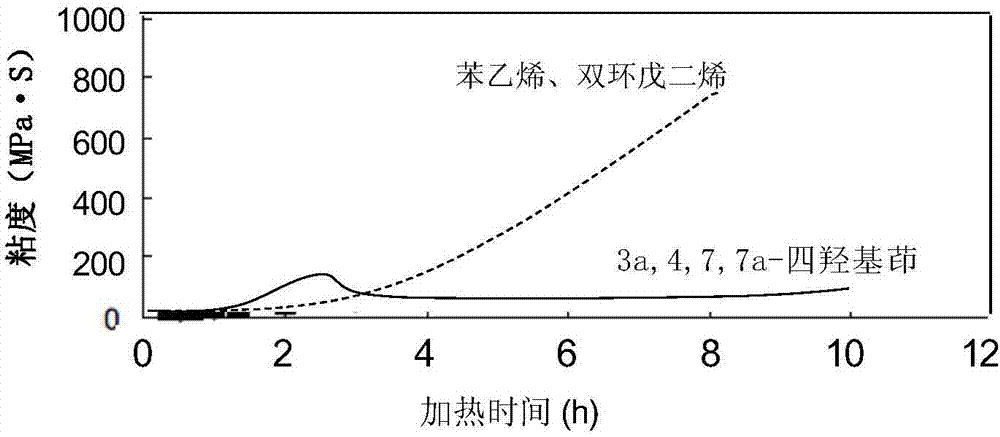

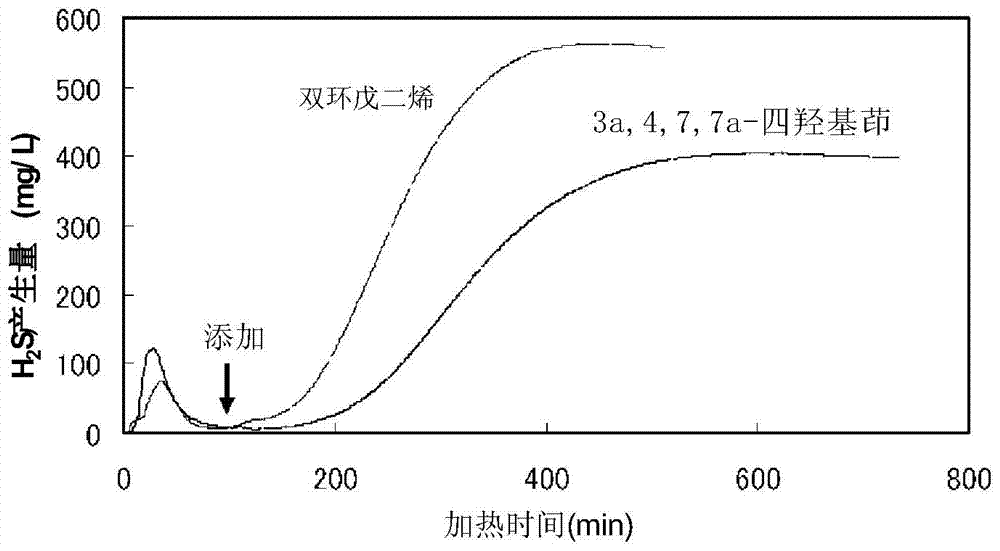

[0042] Step III, sulfur modification: Add the modifier to the molten sulfur in step II and mix evenly, and use the heating equipment to conti...

Embodiment 2

[0072] In this example, the difference from Example 1 is that the prepared high-strength red mud concrete is uniformly mixed with modified sulfur, red mud particles and steel slag particles, and the composition of the high-strength red mud concrete is by weight: Modified sulfur 21%, red mud particles 25%, steel slag 54%; the particle size of the steel slag particles is ≤10mm. During actual preparation, the particle size of the steel slag particles is preferably ≤5mm.

[0073] In this embodiment, when the modified sulfur is prepared, the difference from Example 1 is that the weight ratio of the sulfur in the sulfur mixed solution in step 1 to the ferrous chloride in the ferrous chloride aqueous solution is 500︰15; in step II, use the heating equipment and heat the sulfur mixture in step I at a temperature of 119°C; after the sulfur is completely melted, use the heating equipment and heat The melted sulfur is kept at a constant temperature under the following conditions; when t...

Embodiment 3

[0082] In this example, the difference from Example 1 is that the prepared high-strength red mud concrete is uniformly mixed with modified sulfur, red mud particles and steel slag particles, and the composition of the high-strength red mud concrete is by weight: 23% modified sulfur, 28% red mud particles, 49% steel slag; the particle size of the steel slag particles is ≤10mm. During actual preparation, the particle size of the steel slag particles is preferably ≤5 mm.

[0083]In this embodiment, when the modified sulfur is prepared, the difference from Example 1 is that the weight ratio of the sulfur in the sulfur mixed solution in step 1 to the ferrous chloride in the ferrous chloride aqueous solution is 500:10; in step II, use the heating equipment and heat the sulfur mixture in step I at a temperature of 123°C; after the sulfur is completely melted, use the heating equipment and heat Under the conditions, the melted sulfur is kept at a constant temperature; when the sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com