Electrolytic aluminum anodic steel claw repairing equipment

A technology of electrolytic aluminum anode and steel claw is applied in the field of electrolytic aluminum industry to achieve the effect of reducing labor intensity, strong adaptability and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

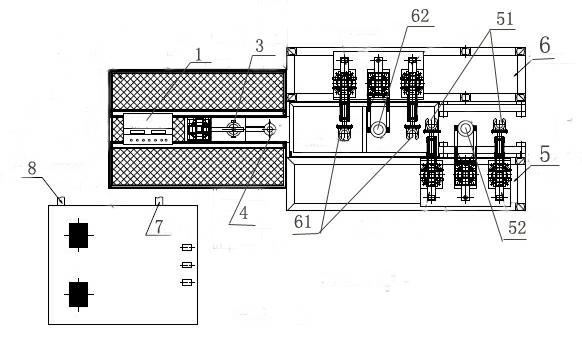

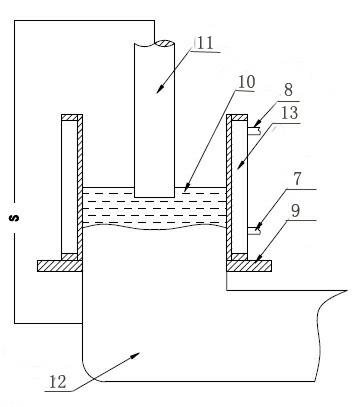

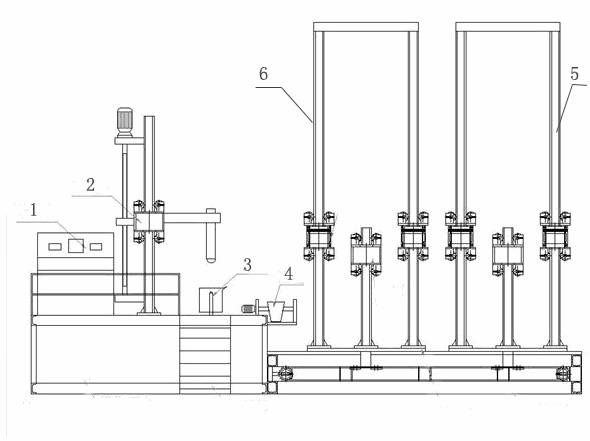

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings: electrolytic aluminum anode steel claw repair equipment, including: an operating platform, a column platform, and the operating platform is provided with a console 1, a slag furnace 2, a crucible 3, and a slag bag 4 , the console 1 is a programmable console, which controls the slag furnace 2, the crucible 3, the slag bag 4 and the column platform through program setting; the column platform is divided into a left column platform 5 and a right column platform 6; The left column platform 5 is provided with a left column car, and the left column car is provided with a steel claw running car 51 and a mold transport vehicle 52; the right column platform 6 is provided with a right column car, and the right column car is provided with a steel claw. Claw trolley 61 and mold delivery vehicle 62; described slag furnace 2, mold delivery vehicle 52, mold delivery vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com