Method for treating aluminum ash in aluminum industrial production

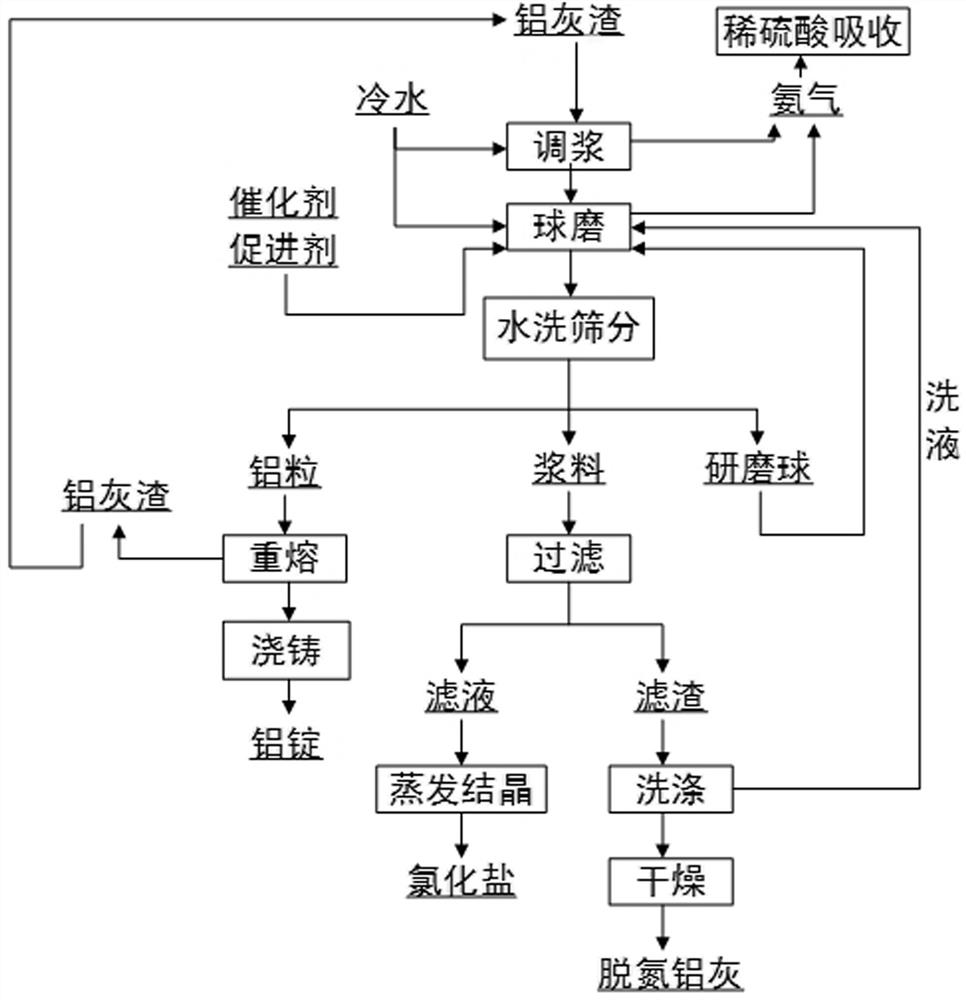

A technology of harmless treatment and aluminum ash, which is applied in the field of aluminum ash treatment in the production of aluminum industry to achieve the effects of reducing dust escape, avoiding flammability and explosion, and saving energy and environmental protection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 The key process parameter investigation experiment of the method for harmless treatment of aluminum ash.

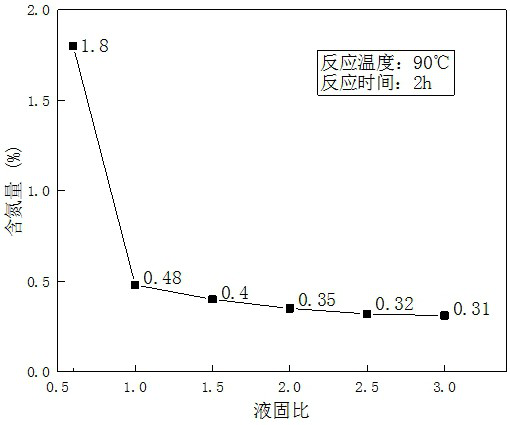

[0063] The key conditions affecting the harmless hydrolysis of aluminum ash in the method for harmless treatment of aluminum ash provided by the present invention are mainly: ball milling reaction temperature, ball milling slurry liquid-to-solid ratio, and ball milling reaction time. The present invention selects the optimal parameter interval through a single factor experiment, and the primary aluminum ash with a nitrogen content of 5.4% is selected for the experiment.

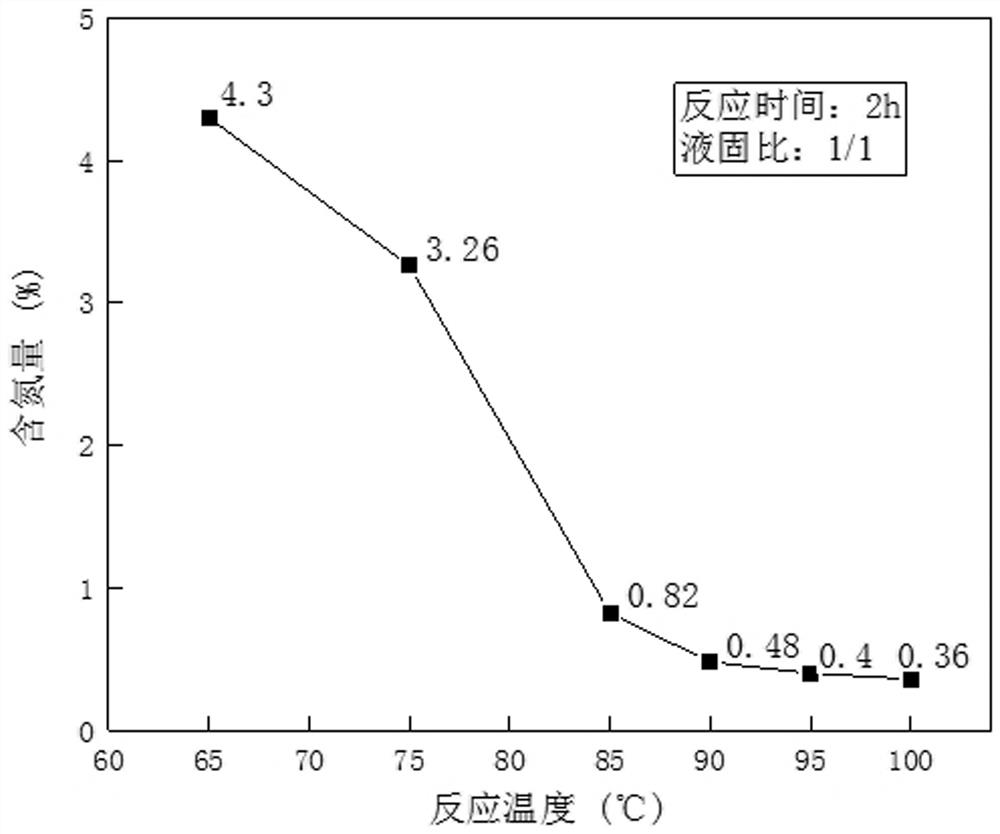

[0064] 1. The influence of reaction temperature on the hydrolysis effect of ball milling.

[0065] The experiment determined that the reaction time was 2 hours, and the liquid-solid ratio of the ball milling reaction slurry was 1:1. By comparing the nitrogen content of aluminum ash powder after hydrolysis by ball milling at reaction temperatures of 65°C, 75°C, 85°C, 95°C, and 100°C, with...

Embodiment 2

[0072] Take 1000kg of aluminum ash to be treated and add it to the mixing tank, add 800kg of water at a temperature of 25°C, start stirring, and stir at a constant speed of 60r / min for about 0.5h. After the ammonia gas generated is discharged from the exhaust port, use dilute Sulfuric acid absorption, the slurry is transported into the wet ball mill tank through the screw feeder, the ball mill tank is pre-installed with 1000kg of grinding balls, and then 200kg of water at 25°C is added to the ball mill tank, and 20kg of sodium carbonate is added as a catalyst and 20kg of concentrated ammonia water As an accelerator, start the ball mill tank and run it at a speed of 60r / min. Heat the slurry in the ball mill tank to make the reaction temperature reach 95°C. The reaction time is 1h. After the gas generated by the reaction is discharged from the exhaust port, it is absorbed by dilute sulfuric acid. After the reaction, the mixture of slurry and grinding balls is poured into a sievin...

Embodiment 3

[0074] Take 1000kg of aluminum ash to be treated and add it to the mixing tank, add 1200kg of water at a temperature of 25°C, start stirring, and stir at a constant speed of 45r / min for about 0.5h. After the ammonia gas generated is discharged from the exhaust port, use dilute Sulfuric acid absorption, the slurry is conveyed into the wet ball milling tank through the screw feeder, and 1500kg of grinding balls are pre-installed in the ball milling tank, and then 400kg of preheated 75°C water is added to the ball milling tank, and 10kg of sodium hydroxide and A mixture of 15kg of calcium oxide is used as a catalyst, 15kg of concentrated ammonia water and 15kg of absolute ethanol are used as accelerators, and the ball milling tank is started at a speed of 50r / min to heat the slurry in the ball milling tank so that the reaction temperature reaches 90°C and the reaction time is 1.5 h. After the gas generated by the reaction is discharged from the exhaust port, it is absorbed with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com