Reaction kettle with filtering function

A reaction kettle and functional technology, applied in the field of reaction kettles with filtering function, can solve the problems of material blockage, easy problems in the processing process, etc., and achieve the effects of high safety, avoiding flammability and explosion, and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

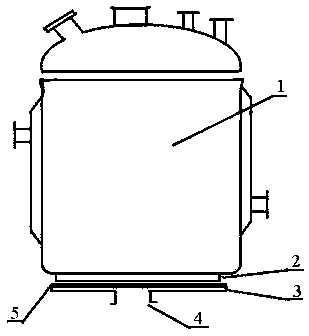

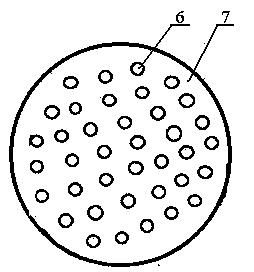

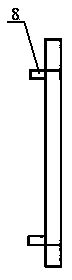

[0012] The present invention will be further described below in conjunction with the drawings:

[0013] Such as figure 1 , figure 2 , image 3 As shown, the present invention relates to a reaction kettle with filtering function, which is provided with a reaction kettle body 1, a large mouth cover 3, a filter plate 2, an annular gasket 5, and is characterized in that the lower end of the reaction kettle body 1 has an open structure and a large mouth cover 3 is installed at the opening of the reactor body 1, and a ring gasket 5 is provided between the opening and the large mouth cover 3. A filter plate 2 is arranged above the large mouth cover 3, and the filter plate 2 is placed on the inner circle of the ring gasket 5. The two are closely matched and placed on the large mouth cover 3, and are fixedly installed on the lower end of the reactor body 1 by the kettle card to achieve the purpose of complete sealing; the filter plate 2 is provided with a number of evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com