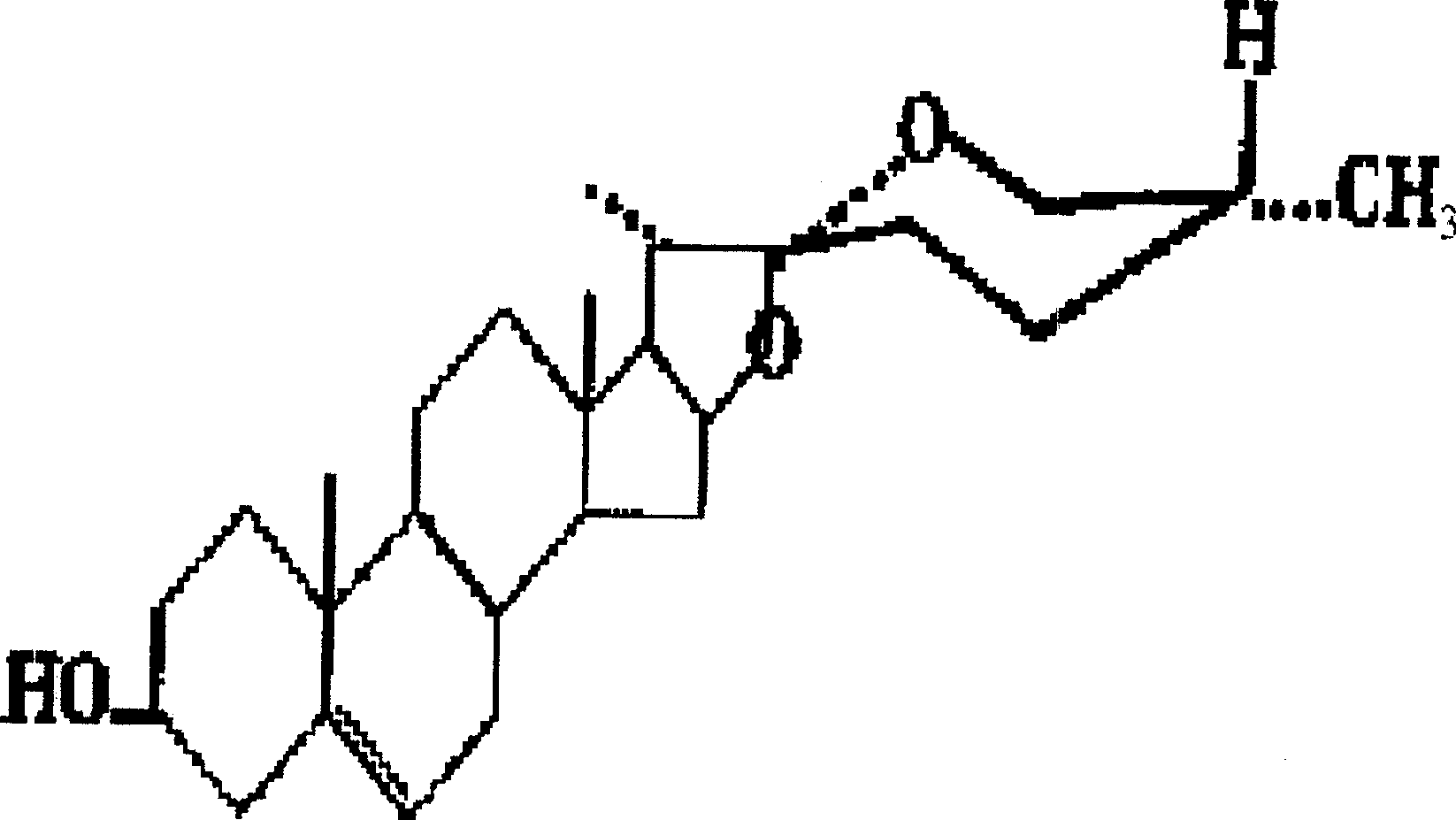

Method for extracting Chinese yam saponin from turmeric

A technology of diosgenin and turmeric, applied in chemical instruments and methods, preparation of steroids, steroidal compounds, etc., can solve the problems of limiting the effective extraction and application of diosgenin, hidden dangers of food safety and production safety, cumbersome process operations, etc. , to achieve the effect of easy operation, avoiding the danger of flammability and explosion, and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

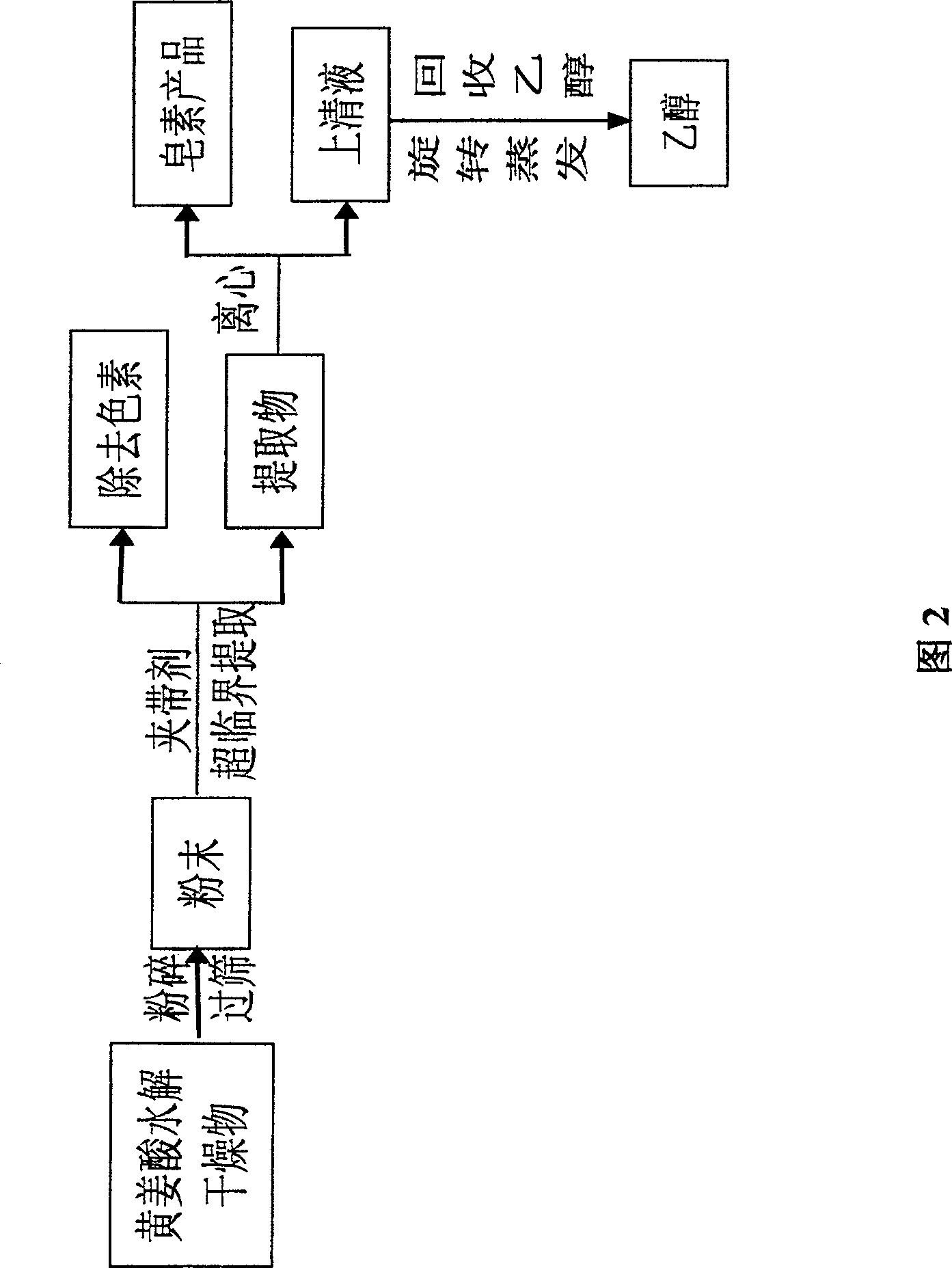

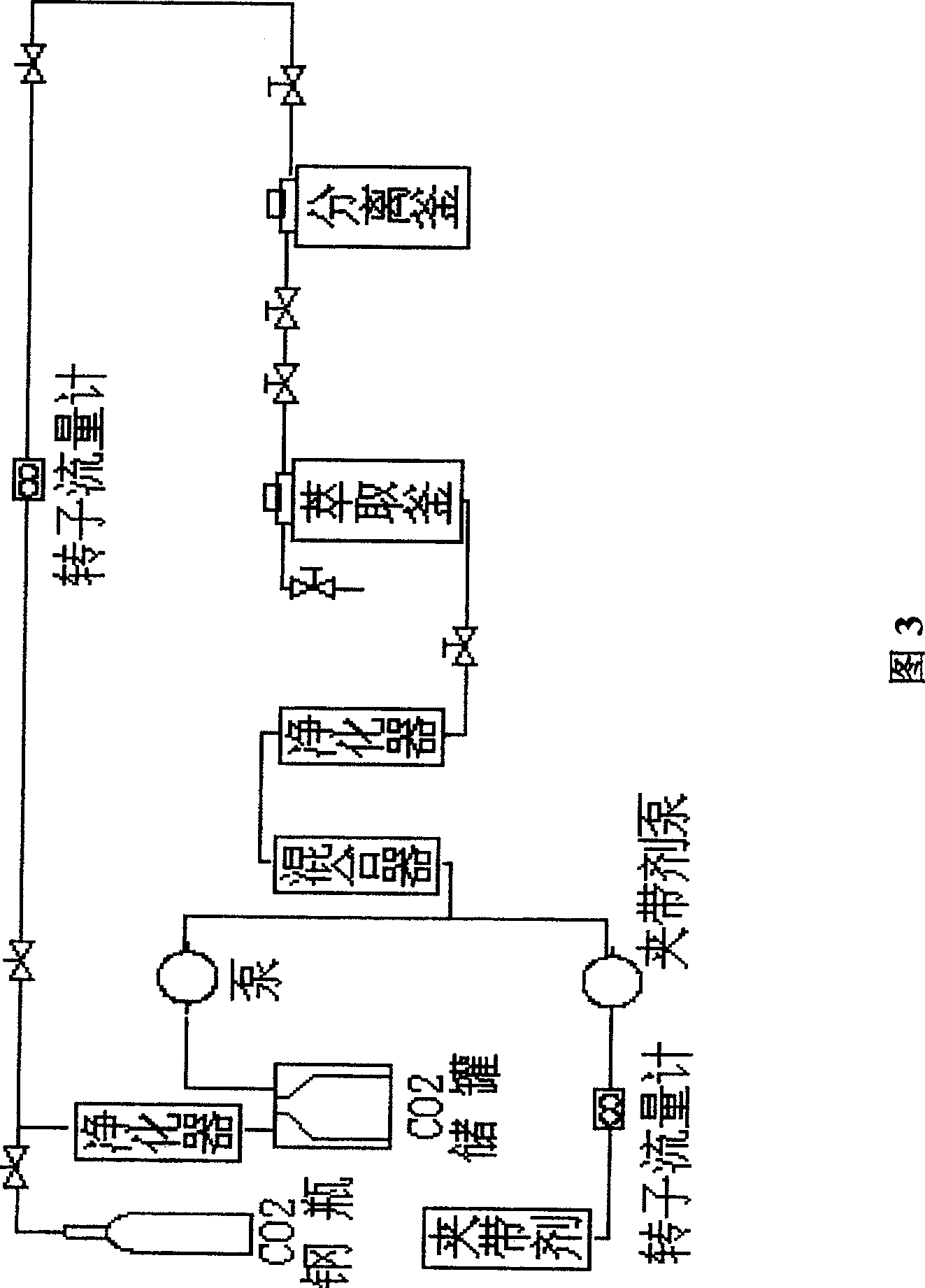

Embodiment 1

[0027]Take by weighing turmeric acid hydrolyzed dried product (self-made, be about to turmeric raw material is separated cellulose through the grinding with water, remove starch by enzymatic method, and obtain after drying after fermentation acid hydrolysis; wherein saponin content is 13.9%.) 2kg, Put into the extraction kettle, add entraining agent (80% ethanol by volume fraction), start to heat the extraction kettle and the separation kettle after sealing, open the carbon dioxide steel cylinder at the same time to let the carbon dioxide enter the storage tank, when the temperature of the extraction kettle and the separation kettle reaches 50°C, At 55°C, open the valve entering the extraction kettle to allow carbon dioxide gas to enter the extraction kettle through the mixer and purifier; open the high-pressure pump to pressurize the extraction kettle. When the extraction pressure reaches 15Mpa, close the valve entering the extraction kettle for static extraction. Then open t...

Embodiment 2

[0029] The same raw materials and operation as in Example 1, the entraining agent all adopts ethanol with a volume fraction of 90%, and 2 kg of turmeric acid hydrolyzed dry matter is fed. The conditions for extracting pigments and other substances are the same as before; when extracting diosgenin, the temperature of the extraction kettle and the separation kettle are 63°C and 45°C respectively, and the pressure of the extraction kettle is 25MPa. After 3 hours of extraction, the main Contains diosgenin extract. The extract was centrifuged or filtered to obtain 302 g of diosgenin product with a purity of 96.5%, mp 210.81° C., and a product yield of 15.1%, meeting the standards for saponin products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com