A kind of aluminum-clad magnesium composite plate/profile and preparation method thereof

A composite plate, aluminum-clad magnesium technology, applied in the field of material processing, can solve the problems of many composite interface oxides, coarse material grains, complicated processes, etc., and achieve the effects of improving use defects, improving performance, and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

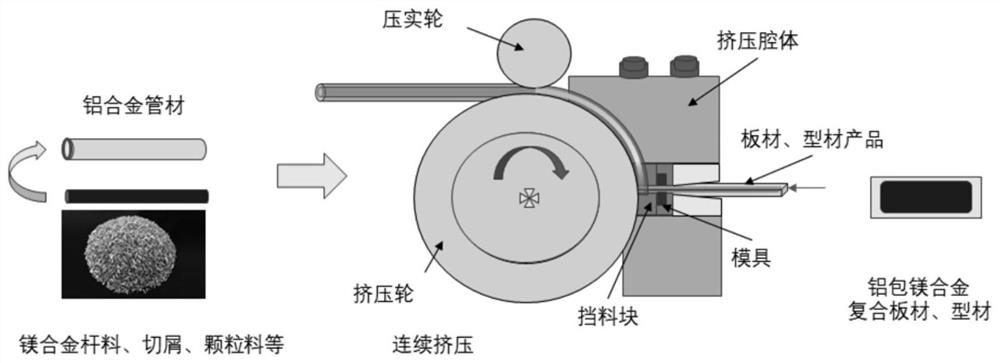

[0032] To prepare aluminum alloy pipes of a certain size, the outer diameter of the pipe is required to match the size of the extrusion wheel groove. For example, if the TLJ250 extrusion equipment is used, the width of the extrusion wheel groove is 8mm, and the aluminum alloy pipe with an outer diameter of 8mm is selected, and the inner diameter is not larger. limit. At the same time, a magnesium alloy core material is prepared, which can be magnesium alloy chips, magnesium alloy pellets, magnesium powder, or a magnesium core containing polymer fillers. Wash the surface of the magnesium alloy core material with dilute acid and alcohol to remove oil and oxides, and then dry it or clean the magnesium shavings. figure 1 It is a schematic diagram of the continuous extrusion forming process of aluminum-clad magnesium alloy sheet / profile, such as figure 1 As shown, feed the magnesium alloy core material into the aluminum alloy pipe and compact it with a press; send the aluminum all...

Embodiment 2

[0035]To prepare aluminum alloy pipes of a certain size, the outer diameter of the pipe is required to match the size of the extrusion wheel groove. For example, if the TLJ250 extrusion equipment is used, the width of the extrusion wheel groove is 8mm, and the aluminum alloy pipe with a diameter of 8mm is selected, and the inner diameter is not limited. . At the same time, prepare magnesium alloy rods or rods that match the inner diameter of the aluminum alloy. For example, if the inner diameter of the aluminum alloy is 5mm, the diameter of the magnesium alloy rod should be 4.5mm-4.9mm, so that the magnesium alloy rod can be inserted into the aluminum alloy pipe smoothly. ; Use alcohol to wipe the surface of the magnesium alloy core material to remove oil and oxides, and then use a metal brush for brushing to increase the composite effect of the composite interface. Insert the magnesium alloy rod material into the aluminum alloy pipe and compact it with a press. Send the alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com