Method for synthesizing cyclopentanol by continuous flow microreactor

A micro-reactor, micro-channel reactor technology, applied in chemical instruments and methods, sulfate preparation, chemical/physical/physical-chemical processes, etc., can solve problems such as low conversion rate of raw materials, many by-products, and environmental pollution. , to achieve the effect of improving the conversion rate of raw materials, low total cost, low energy consumption and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

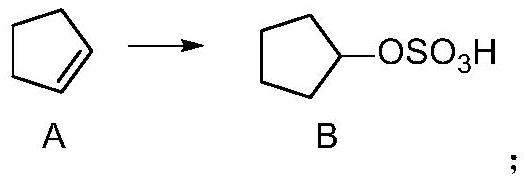

[0052] The preparation of embodiment 1 compound B

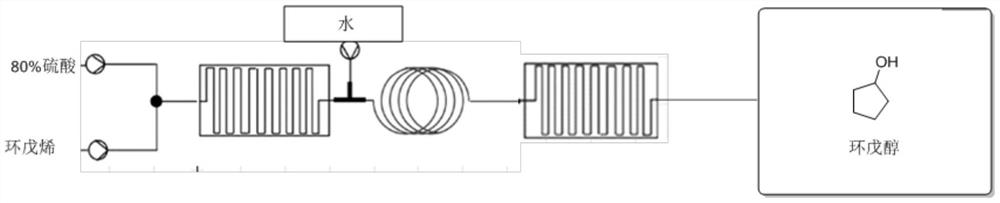

[0053]

[0054] Put 1 mol of cyclopentene in storage bottle A, 1.2 mol of 80% sulfuric acid aqueous solution in storage bottle B, set the reaction temperature to 30°C, and use two plunger-type metering pumps for the materials in A and B bottles respectively Pump into the microchannel responder at a flow rate of 1:1.2, the residence time is 2 minutes, collect the liquid product, and monitor the complete reaction by HPLC. After the reaction liquid flows out, it enters the post-processing system. After extraction, drying, and removal of the organic solvent, compound B is obtained. , with a purity of 99.5% and a yield of 94%.

Embodiment 2

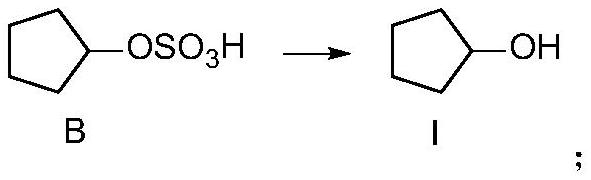

[0057] The preparation of embodiment 2 cyclopentanols

[0058]

[0059] Put the compound B and water obtained in Example 1 in the liquid storage bottle C, set the reaction temperature to 90°C, and pump the materials in the compound B and C bottles into the microchannel at a flow rate of 1:1 with two plunger-type metering pumps In the reactor, the residence time is 10min, the liquid product is collected, and the reaction is completely monitored by HPLC. After the reaction liquid flows out, it enters the post-processing system. After extraction, drying, and removal of the organic solvent, cyclopentanol is obtained with a purity of 98.5%. 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com