Concrete efficient expending agent employing aluminum-containing industrial waste residues as well as preparation method and application of concrete efficient expending agent

A high-efficiency expansion agent and industrial waste residue technology, applied in the field of concrete high-efficiency expansion agent, can solve the problems of less dissolution, poor excitation effect, low expansion efficiency, etc., achieve large expansion efficiency, compensate for early and mid-late shrinkage, and greatly limit expansion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

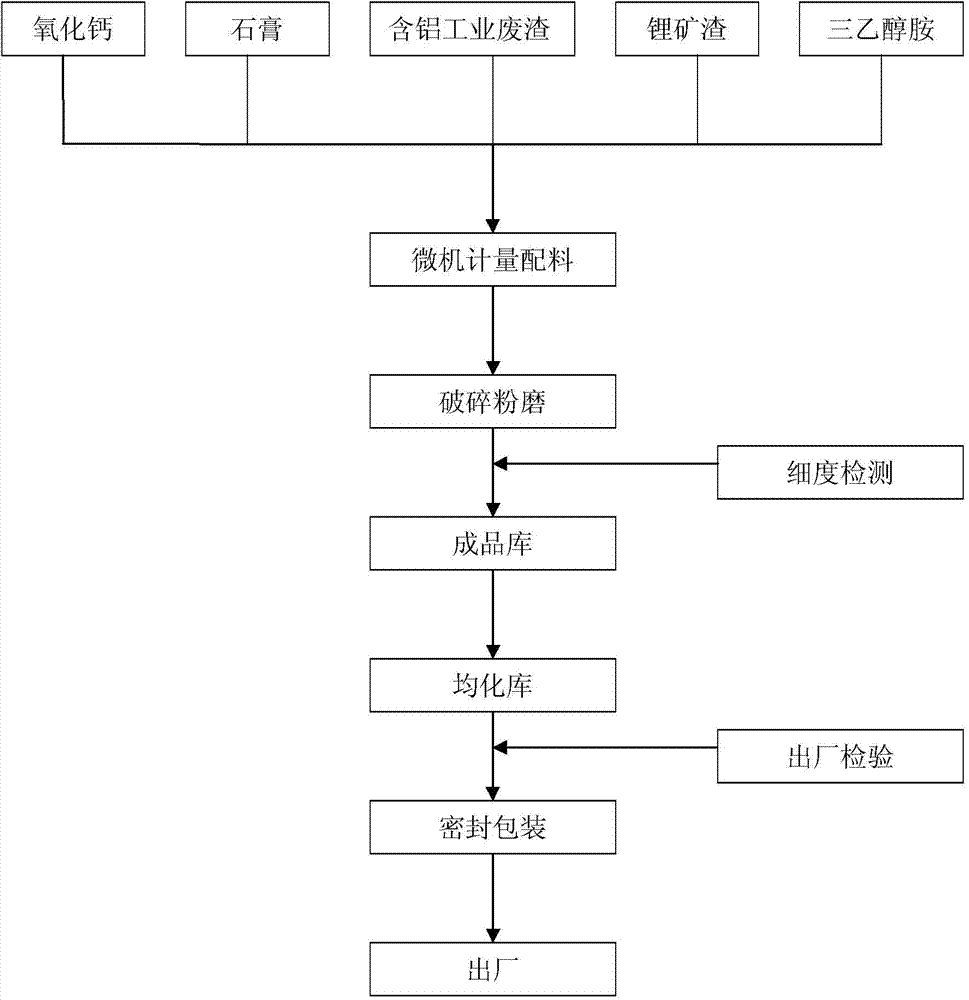

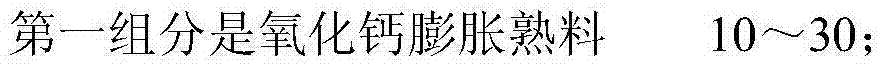

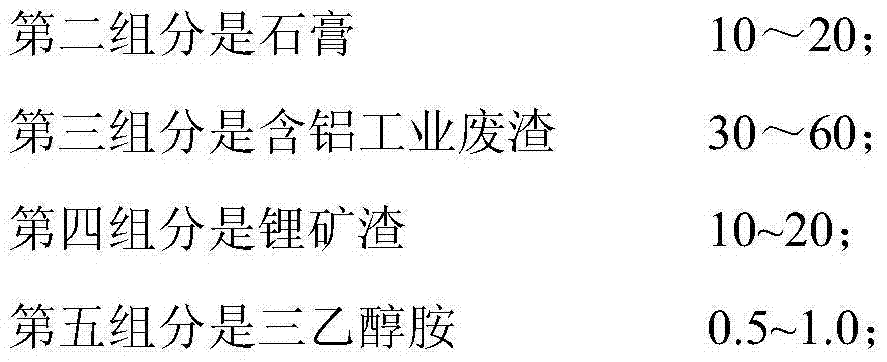

[0038] Get calcium oxide expanded clinker 10, dihydrate gypsum 20, primary fly ash 50, lithium slag 19.5, triethanolamine 0.5 by weight ratio, and the above components are figure 1 Process flow After mixing and grinding, homogenization is used to obtain a high-efficiency concrete expansion agent HME-1 of the present invention using aluminum-containing industrial waste residues.

[0039] Adopt the benchmark cement specified in GB8076, mix 10% of the expansion agent prepared by the present invention in the cement, and test according to the provisions of GB23439-2009 "Concrete Expansion Agent", its physical properties are shown in Table 1.

[0040] Table 1

[0041]

Embodiment 2

[0043] Get calcium oxide expanded clinker 15, phosphogypsum 18, first-grade fly ash 51.2, lithium slag 15, triethanolamine 0.8 by weight and number ratio, and above-mentioned components are pressed figure 1 Process flow After mixing and grinding, homogenization is used to obtain a high-efficiency concrete expansion agent HME-2 of the present invention using aluminum-containing industrial waste slag.

[0044] Using the standard cement stipulated in GB8076, 10% of the expansion agent prepared by the present invention is mixed into the cement, and tested according to the provisions of GB23439-2009 "Concrete Expansion Agent", and its physical properties are shown in Table 2.

[0045] Table 2

[0046]

Embodiment 3

[0048] Get calcium oxide expanded clinker 19, dihydrate gypsum 20, secondary fly ash 40, lithium slag 20, triethanolamine 1.0 by weight and number ratio, and the above-mentioned components are pressed figure 1 Process flow After mixing and grinding, homogenization is used to obtain a high-efficiency concrete expansion agent HME-3 of the present invention using aluminum-containing industrial waste residues.

[0049] Using the standard cement stipulated in GB8076, 10% of the expansion agent prepared by the present invention is mixed into the cement, and tested according to the provisions of GB23439-2009 "Concrete Expansion Agent", and its physical properties are shown in Table 3.

[0050] table 3

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com