Production line for preparing concrete blocks

A technology for concrete blocks and production lines, applied in manufacturing tools, auxiliary molding equipment, ceramic molding workshops, etc., can solve the problems of high energy consumption, increased production costs, low utilization rate of steel slag resources, and reduced use practicability, etc. Utilization rate, good social and economic benefits, and the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

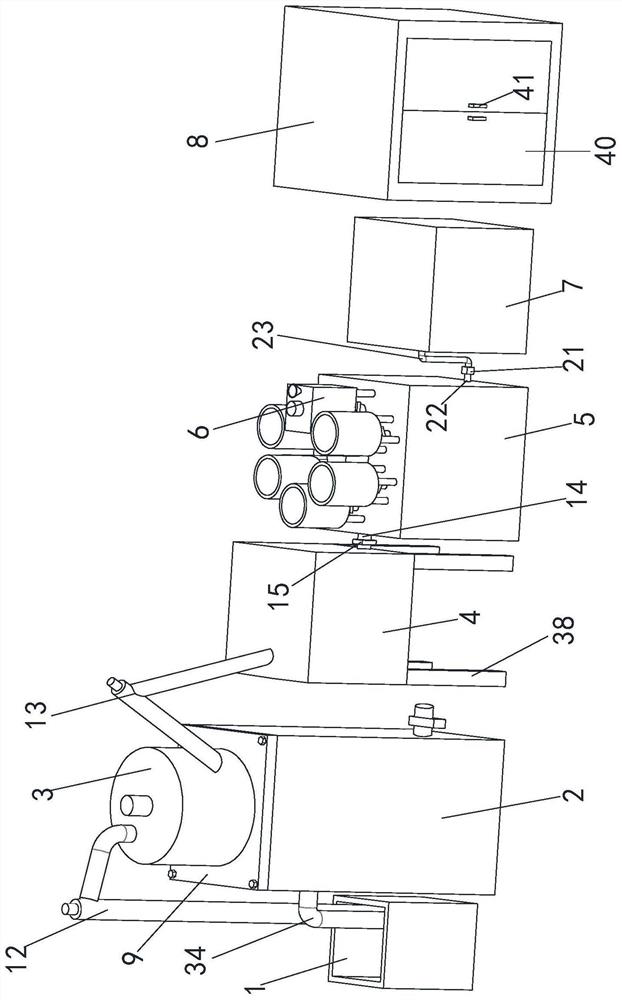

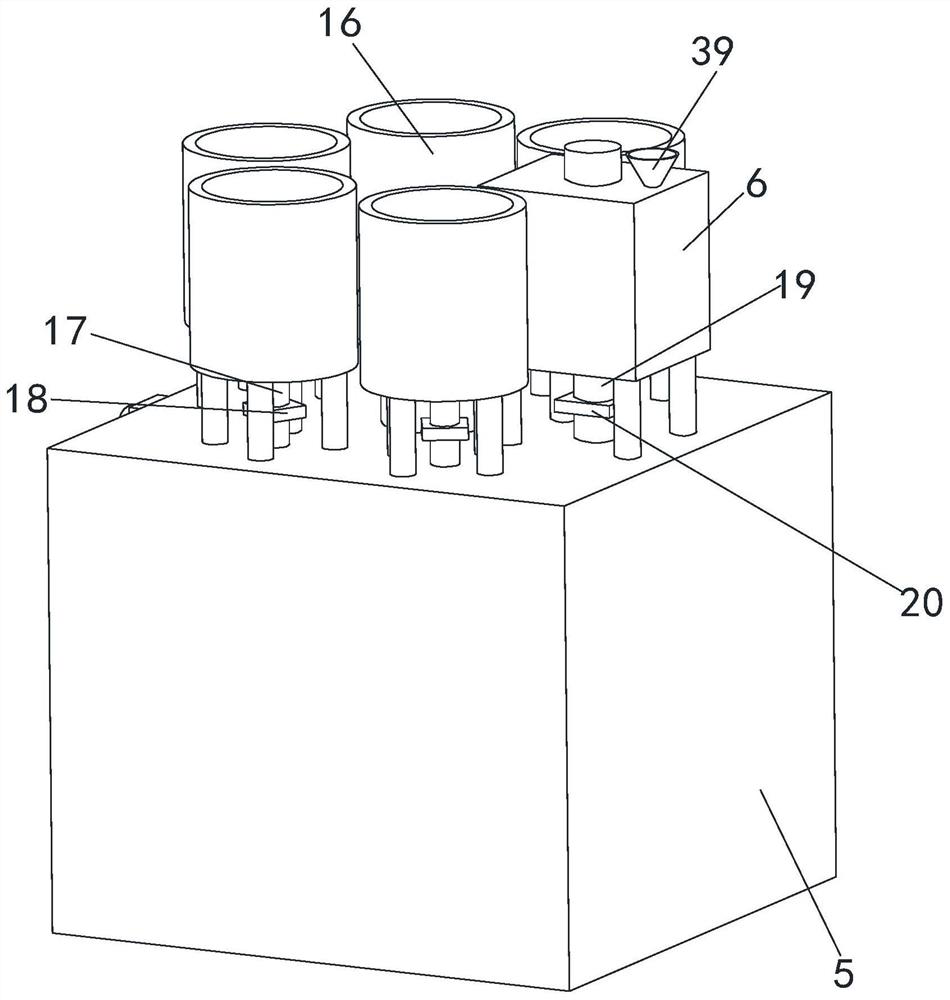

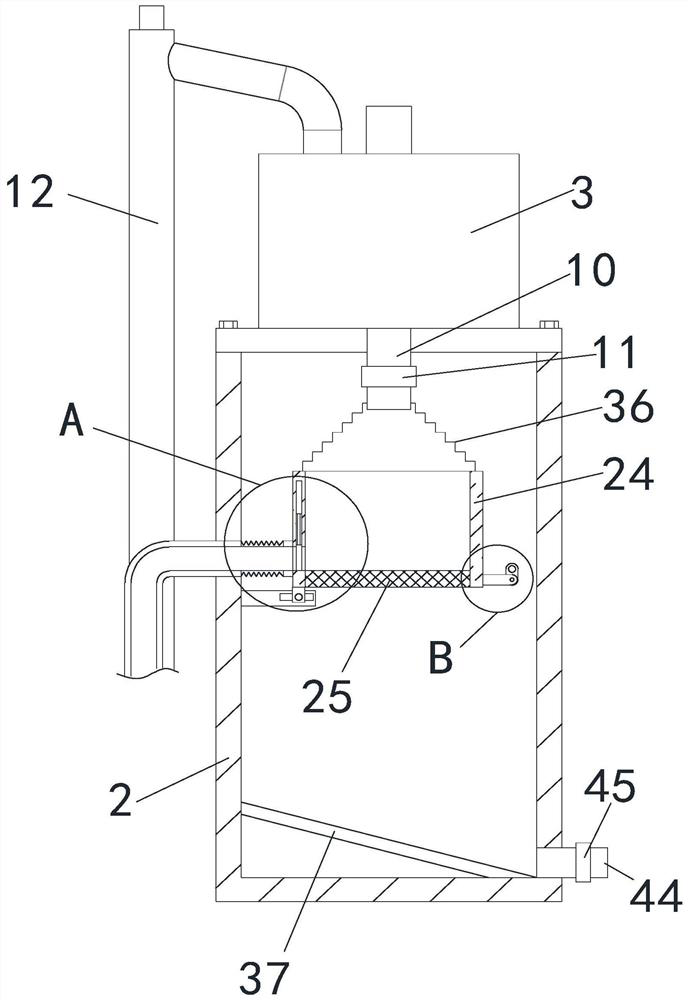

[0034] see Figure 1-6 , a production line for preparing concrete blocks, comprising a feeding box 1, a screening box 2, a crushing magnetic separation device 3, a dehydration device 4, a first mixing box 5, a second mixing box 6, an injection molding device 7 and a heat preservation chamber 8, The top of the screening box 2 is equipped with a top plate 9, the inside of the screening box 2 is provided with a screening device, the bottom of the screening box 2 is fixedly connected with a material guide plate 37, and the bottom side of the right end of the screening box 2 is connected with a discharge pipe 44. A fifth electromagnetic valve 45 is installed on the material pipe 44, and the screened steel slag fine sand is discharged through the discharge pipe 44 and added to the storage barrel 16 containing the steel slag fine sand, and the bottom end of the magnetic separation device 3 and the top plate 9 are crushed. The top of the crushing magnetic separation device 3 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com