Steel slag-based oil well cement expanding agent and application thereof in oil well cement

The technology of oil well cement and expansion agent is applied to steel slag-based oil well cement expansion agent and its application field in oil well cement, and can solve the problems of function, steel slag expansion agent is difficult to adapt to cementing operation, and its performance cannot meet cementing environment. Achieve the effect of reducing production costs, reducing micro-gap and waste of oil and gas resources, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

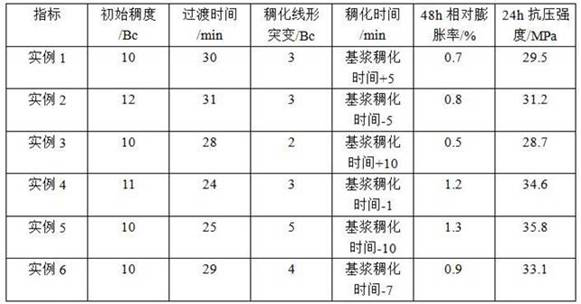

Embodiment 1

[0034] The oil well cement expansion agent in this implementation comprises the following components in parts by weight: 700 parts of steel slag, 100 parts of magnesite, 75 parts of dolomite, and 55 parts of periclase. The steel slag powder, magnesite, dolomite and periclase are mixed according to the above parts by weight and then ground to a specific surface area of 260 m 2 / kg, added to G-grade oil well cement at a dosage of 13%, and tested according to the standard "SY / T-5504.8-2013 Oil Well Cement Admixture Evaluation Method-Part 8 Expansion Agent". The results are shown in Table 1.

Embodiment 2

[0036] The oil well cement expansion agent in this implementation comprises the following components in parts by weight: 710 parts of steel slag, 100 parts of magnesite, 100 parts of dolomite, and 50 parts of periclase. The steel slag powder, magnesite, dolomite and periclase are mixed according to the above parts by weight and then ground to a specific surface area of 350 m 2 / kg, added to G-grade oil well cement at a dosage of 8%, and tested according to the standard "SY / T-5504.8-2013 Oil Well Cement Admixture Evaluation Method-Part 8 Expansion Agent". The results are shown in Table 1.

Embodiment 3

[0038] The oil well cement expansion agent of this implementation comprises the following components in parts by weight: 710 parts of steel slag, 110 parts of magnesite, 75 parts of dolomite, and 60 parts of periclase. The steel slag powder, magnesite, dolomite, and periclase are mixed according to the above parts by weight and then ground to a specific surface area of 300 m 2 / kg, added to grade G oil well cement at a dosage of 5%, and tested according to the standard "SY / T-5504.8-2013 Oil Well Cement Admixture Evaluation Method - Part 8 Expansion Agent". The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com