Sulphur-containing bauxite gravity concentration and desulphurization method

A bauxite and pulp technology, which is applied in the field of mineral processing engineering, can solve the problems of difficulty in concentration and filtration of flotation concentrate foam, high production cost, failure to popularize and apply, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

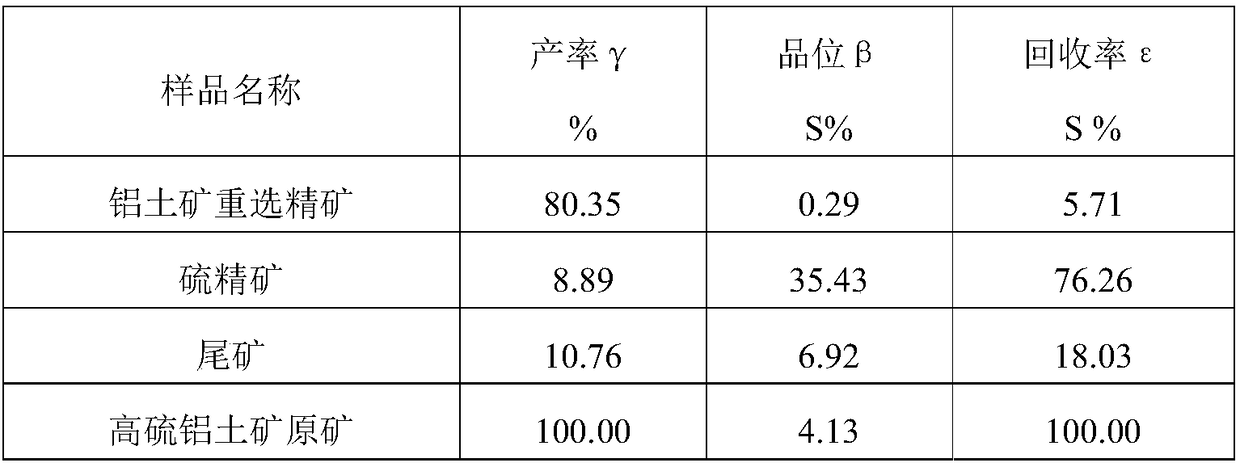

[0034] Take the high-sulfur bauxite with a sulfur grade of 4.13% (that is, the mass percentage content of S in the bauxite is 4.13%), and carry out gravity desulfurization, including the following steps:

[0035] 1. Use a crusher to first crush the high-sulfur bauxite ore, and then use a ball mill to grind the ore until the particle size is less than 0.074mm. The yield accounts for 50%, and the high-sulfur bauxite raw ore powder is obtained;

[0036] 2. The high-sulfur bauxite raw ore powder obtained by grinding is adjusted into pulp with water, and the solid concentration of the pulp is 18%, so as to obtain the high-sulfur bauxite raw ore pulp;

[0037] 3. Use spiral chute for gravity separation and roughing, remove sulfur-containing mineral middlings from the high-sulfur bauxite raw ore slurry, and obtain bauxite roughing products, and the separated high-density material is sulfur-containing middling minerals;

[0038] 4. Use the spiral chute for gravity separation and conce...

Embodiment 2

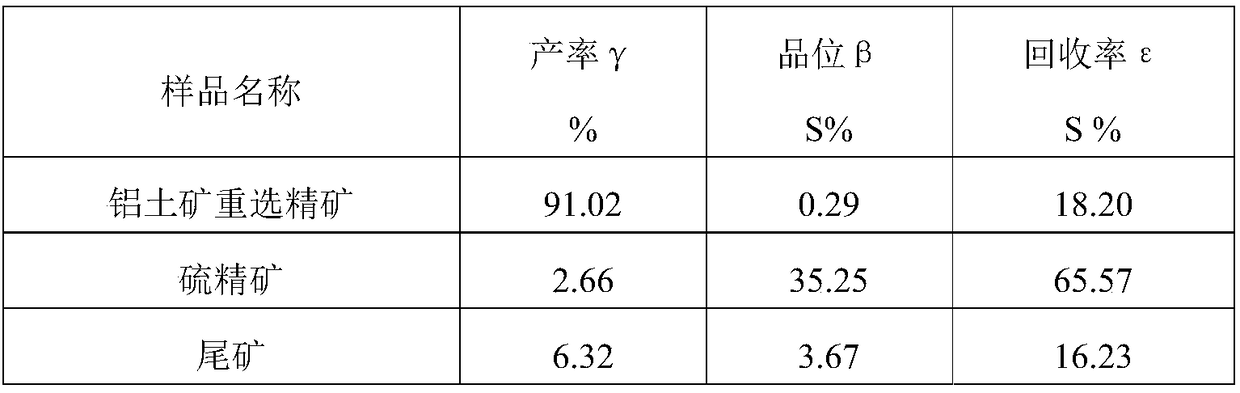

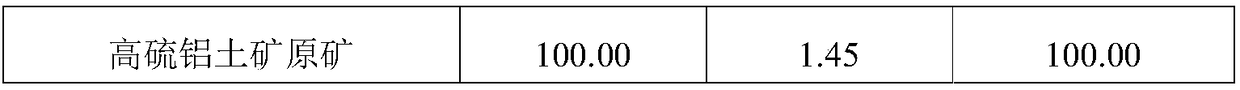

[0045] Take the high-sulfur bauxite with a sulfur grade of 1.45%, and carry out gravity desulfurization, including the following steps:

[0046] 1. Use a crusher to first crush the high-sulfur bauxite ore, and then use a high-pressure roller mill to grind the ore until the particle size is less than 0.074mm. The yield accounts for 65%, and the high-sulfur bauxite raw ore powder is obtained;

[0047] 2, the high-sulfur bauxite raw ore slag obtained by grinding is adjusted into a slurry with a mass percentage concentration of 18% liquid alkali solution (liquid alkali solution is sodium hydroxide solution), and the solid concentration of the slurry is 20%, obtaining high Sulfurite raw ore slurry;

[0048] 3. Use spiral chute for gravity separation and roughing, remove sulfur-containing mineral middlings from the high-sulfur bauxite raw ore slurry, and obtain bauxite roughing products, and the separated high-density material is sulfur-containing middling minerals;

[0049] 4. Use...

Embodiment 3

[0057] Take the high-sulfur bauxite with a sulfur grade of 1.03%, and carry out gravity desulfurization, including the following steps:

[0058] 1. Use a high-pressure roller mill to crush and grind the ore until the particle size is less than 0.074mm. The yield accounts for 80%, and the raw ore powder of high-sulfur bauxite is obtained;

[0059] 2. The high-sulfur bauxite raw ore powder obtained by grinding is adjusted into pulp with water, and the solid concentration of the pulp is 12%, so as to obtain the high-sulfur bauxite raw ore pulp;

[0060] 3. Use a spiral concentrator to carry out gravity separation and roughing, remove the middle ore of sulfur-containing minerals from the raw ore slurry of high-sulfur bauxite, and obtain the rough separation product of bauxite, and the separated material with high density is middle ore of sulfur-containing minerals ;

[0061] 4. Using a spiral concentrator for re-election and concentration, the medium ore of sulfur-containing mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com