Device and method for coupling lithium extraction and hydrogen production of electrically-assisted photocatalytic lithium iron phosphate waste

A technology of lithium iron phosphate and photocatalysis, which is applied in battery recycling, electrolysis components, electrolysis process, etc., can solve the problems of acidic wastewater and waste residue, poor economy, etc., and achieve the effect of improving oxidation, simple steps, and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

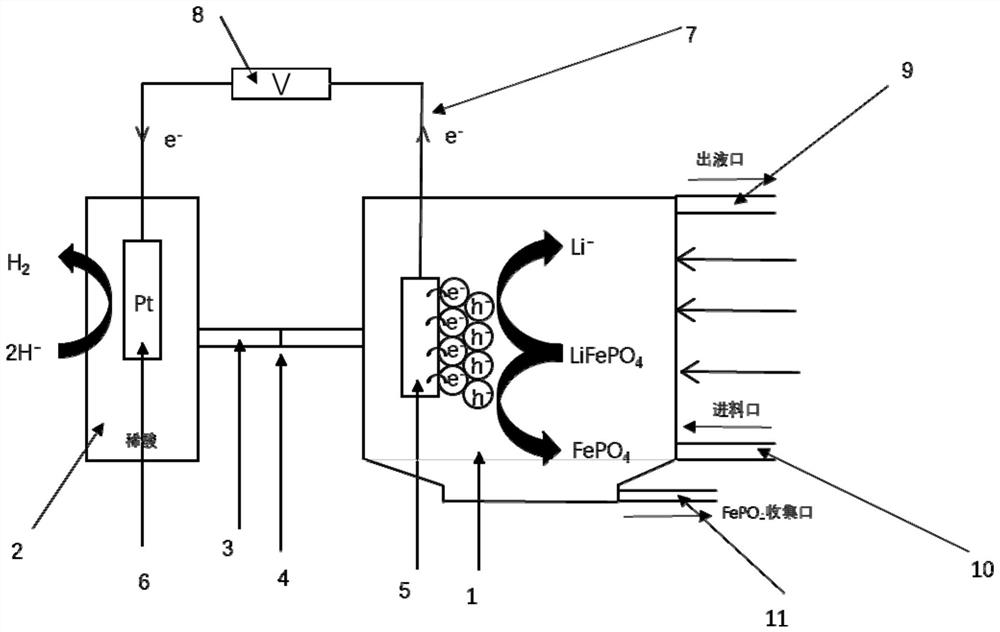

[0061] The electrically assisted photocatalytic system of the present embodiment comprises an H-type electrocatalytic cell with a proton film and a photocatalytic system, the TiO 2 Nanomaterials are coated with TiO of anode electrode 5 by electrode deposition as photocatalytic materials 2 On the nanotube sheet; the solid-liquid ratio of 10g / ml of the broken waste lithium iron phosphate battery of the positive black powder mixture through the anode pool 10 into the anode pool 10, wherein the waste lithium iron phosphate battery cathode black powder particle size of 0.3mm; cathode pool 2 filled with hydrogen ion concentration of 0.1mol / L dilute sulfuric acid;

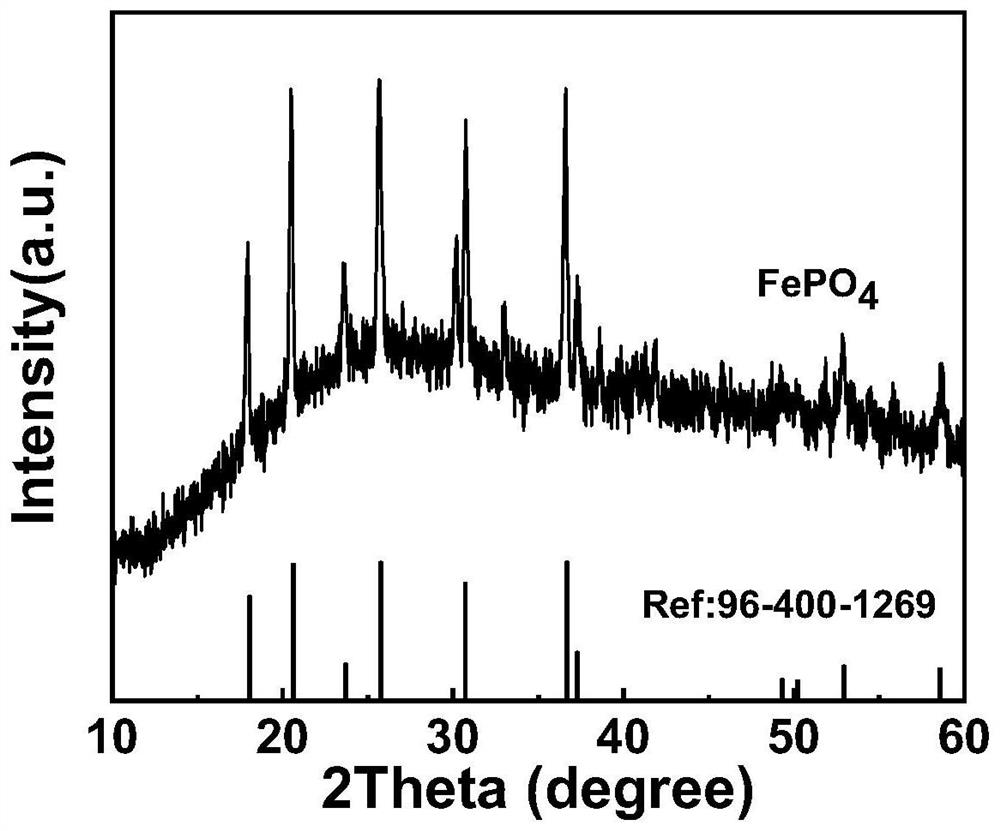

[0062]Turn on the UV lamp with a power of 40w, Open the additional DC power supply 8 is 1.5v DC voltage; under the illumination of ultraviolet light, the black powder of the waste iron phosphate battery in anode pool 1 is reacted to obtain iron phosphate precipitation and lithium ions released in the solution, the role of...

Embodiment 2

[0065] The electrically assisted photocatalytic system of the present embodiment comprises an H-type electrocatalytic cell with a proton film and a photocatalytic system, LaFeO 3 The nanomaterial as a photocatalytic material is coated on the FTO sheet of the anode electrode 5 in a rotating coating manner; the solid-liquid ratio of 8g / ml of the broken waste lithium iron phosphate battery cathode black powder aqueous mixture through the anode pool 10 through the anode pool 10 into the anode pool 1, wherein the waste lithium iron phosphate battery cathode black powder particle size of 1.0mm; cathode pool 2 filled with hydrogen ion concentration of 0.2mol / L dilute hydrochloric acid;

[0066] Turn on the xenon lamp with a power of 150w, Open the additional DC power supply 8 is a DC voltage of 0.5v; under the illumination of the light source, the black powder of the waste iron phosphate battery in anode pool 1 reacts to obtain iron phosphate precipitation and lithium ions released i...

Embodiment 3

[0068] The electrically assisted photocatalytic system of the present embodiment comprises an H-type electrocatalytic cell with a proton film and a photocatalytic system, the MOF-based catalyst UIO-66-NH 2The material is coated on the ITO sheet of the anode electrode 5 in a scraper coating manner; the solid-liquid ratio of 1g / ml of the crushed waste lithium iron phosphate battery cathode black powder aqueous mixture through the anode pool 10 through the anode pool 10 into the anode pool 1, wherein the waste lithium iron phosphate battery cathode black powder particle size of 0.8mm; cathode pool 2 filled with hydrogen ion concentration of 0.5mol / L dilute hydrochloric acid;

[0069] Using sunlight as a light source, Open the plus DC power supply 8 is 0.01v DC voltage; under the illumination of the light source, the black powder of the waste iron phosphate battery in anode pool 1 is reacted to obtain iron phosphate precipitation and lithium ions released in solution, the role of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com