Carbon dioxide sorbent based on ordered mesoporous carbon and preparation method

A carbon dioxide and mesoporous carbon technology, applied in the field of materials, can solve the problems of carbon dioxide adsorption performance to be improved, untested carbon dioxide adsorption performance, uneven pore size of raw materials, etc., to achieve good reproducibility, reduced adsorption performance, and enhanced adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

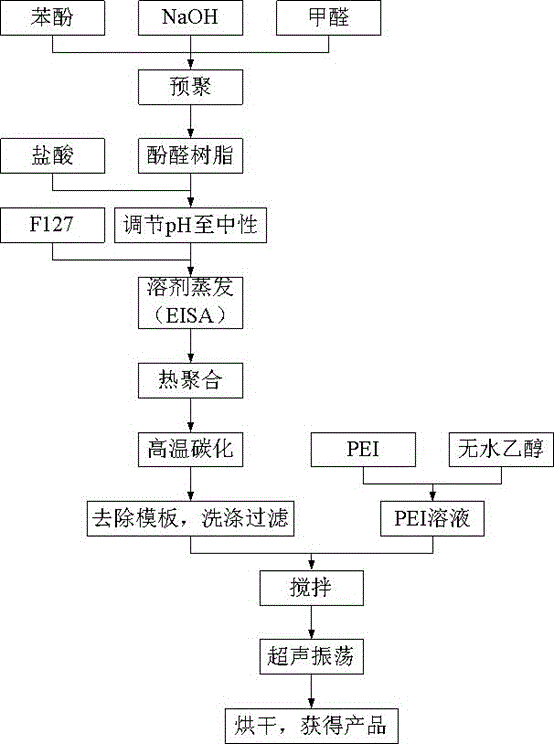

[0022] The present invention proposes a carbon dioxide adsorbent based on ordered mesoporous carbon and its preparation method, which is characterized in that: the steps of the method are as follows:

[0023] (1) Mix phenol with 20% NaOH solution at normal temperature and pressure, stir at constant temperature, add formaldehyde solution drop by drop, stir at constant temperature and cool to room temperature; adjust the pH value to about 7 with low-concentration hydrochloric acid , and then evaporated at 45°C for 24h to obtain a resol-type phenolic resin.

[0024] (2) Dissolve the phenolic resin and F127 obtained in step 1 into ethanol, mix and stir, transfer to a flat-bottomed petri dish and let it stand still; heat the sample to complete thermal polymerization, and then put the product into a vacuum tube furnace in a nitrogen protective atmosphere High-temperature calcination; grind the carbonized material into powder and add it to concentrated sulfuric acid to heat to remove...

Embodiment 1

[0027] Under normal temperature and pressure conditions, 6.1 parts by weight of phenol and 1.3 parts by weight of NaOH solution with a mass fraction of 20% were mixed, stirred at a constant temperature, and 10.5 parts by weight of a formaldehyde solution with a mass fraction of 37% was added dropwise, cooled to room temperature after constant temperature stirring ; Adjust the pH value to about 7 with low-concentration hydrochloric acid, and then evaporate at 45°C for 24 hours to obtain a resol-type phenolic resin.

[0028] Dissolve the obtained phenolic resin and F127 in ethanol, mix, stir, heat and calcinate, grind the carbonized material into powder, add it to concentrated sulfuric acid and heat to remove the template, then repeatedly wash with water and absolute ethanol, filter and dry to obtain ordered mesoporous carbon.

Embodiment 2

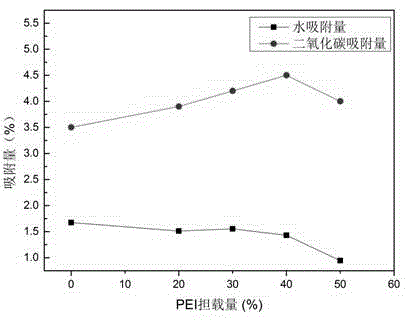

[0030] 1.12 parts by weight of PEI was added into methanol to prepare a PEI solution, 4.48 parts by weight of the ordered mesoporous carbon in Example 1 was added, stirred and ultrasonically oscillated for more than 10 minutes. Put the sample into an oven to dry, and finally obtain the ordered mesoporous carbon with a PEI loading of 20%, that is, the product. After testing, the product has good hydrophobicity and carbon dioxide adsorption performance at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com