Synthesis method of composite film for adsorbing Hg < 2 + > in wastewater

A composite film and synthesis method technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of limited adsorption membrane treatment effect, non-recyclable utilization, high operating cost, etc. Achieve the effect of low density, novel method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

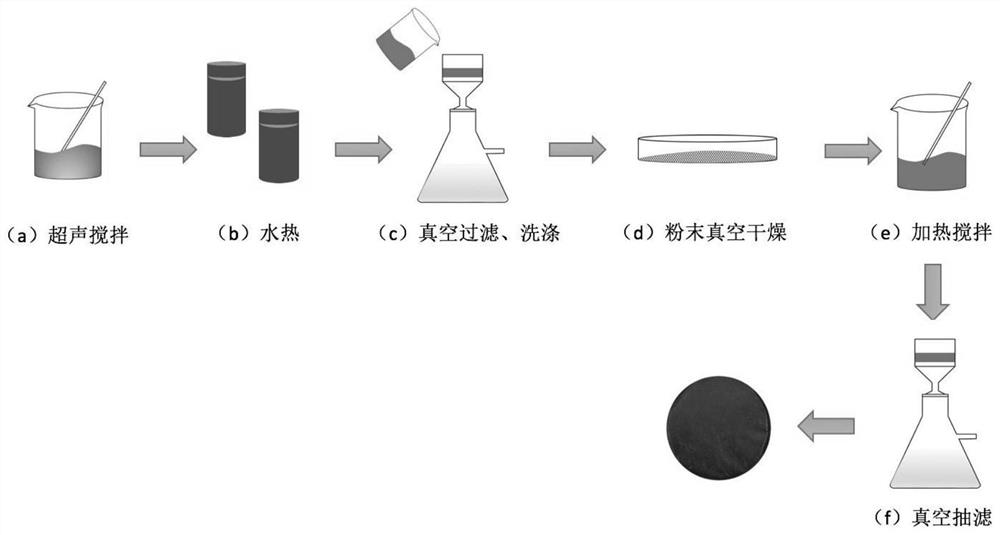

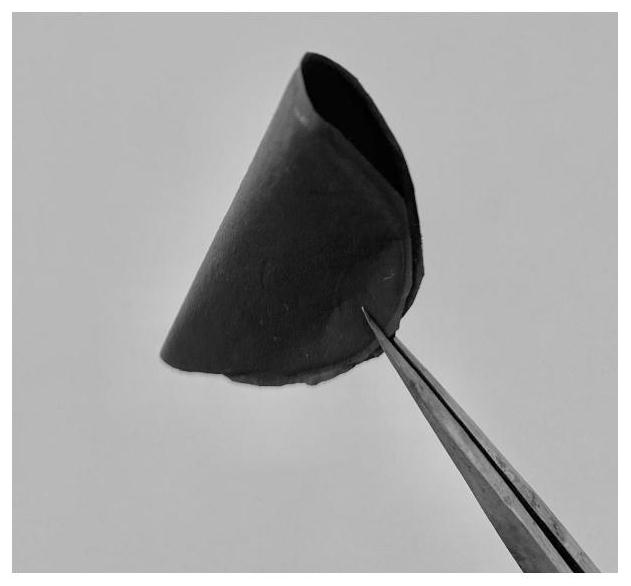

[0030] The application discloses a method for adsorbing Hg in wastewater 2+ The synthetic method of composite thin film, it comprises: polyvinylidene fluoride / multi-walled carbon nanotube / polyethylene glycol composite base film, MXene hybrid Fe 2 o 3 Nano particle active layer, cellulose surface covering film. The composite film synthesized by this method has a very excellent effect of degrading organic pollutants.

[0031] The composite film disclosed in this application includes: polyvinylidene fluoride / multi-walled carbon nanotube / polyethylene glycol composite bottom film, MXene hybrid Fe 2 o 3 Nano particle active layer, cellulose surface covering film;

[0032] The polyvinylidene fluoride / multi-walled carbon nanotube / polyethylene glycol composite bottom film has a void structure,

[0033] The MXene hybrid Fe 2 o 3 The nanoparticle active layer has a layered structure, combined with the polyvinylidene fluoride / multi-walled carbon nanotube / polyethylene glycol composi...

Embodiment 1

[0064] The amount of active substance in the synthesis

[0065] MXene@Fe 2 o 3 Actual MXene content in hybrid nanoparticles: 1.65mg

[0066] MXene@Fe 2 o 3 Actual Fe in hybrid nanoparticles 2 o 3 Content: 63.36mg

[0067] Volume of surface covering cellulose dispersion: 1.5mL

[0068] Hg removal 2+ See Table 1 for wastewater conditions.

[0069] Table 1 Reaction Conditions

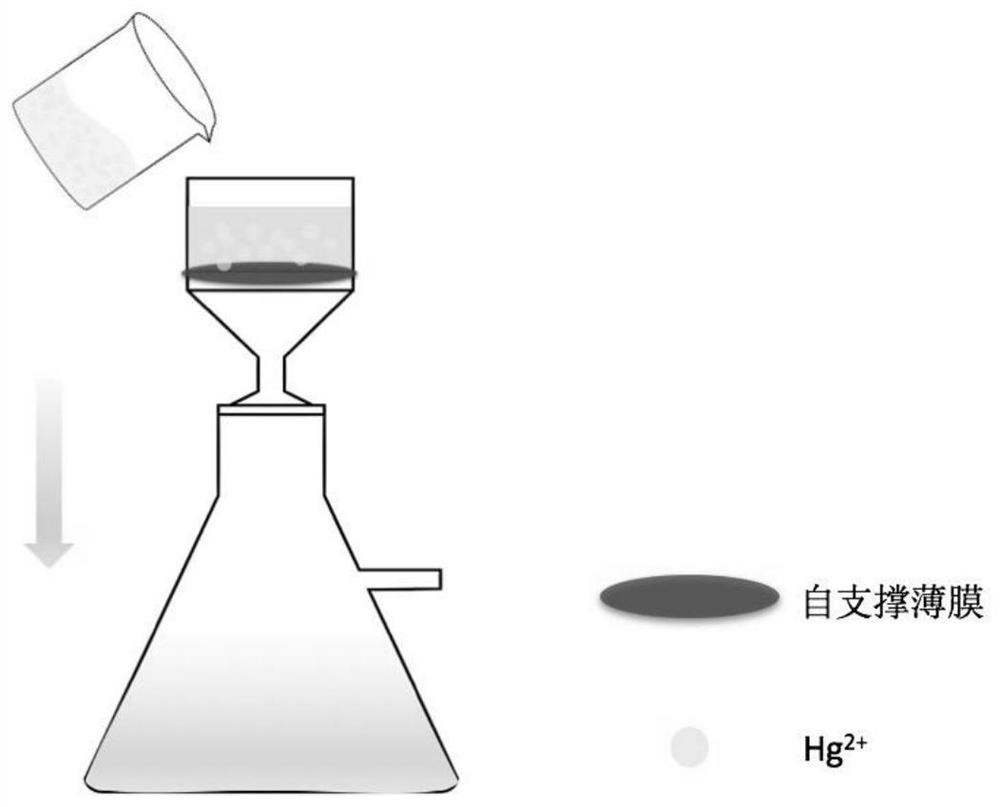

[0070] condition scope Film area 12.56cm 2

[0071] Under the above conditions to remove Hg 2+ Wastewater treatment can achieve 97-98% efficiency, and the flux is 32-33L / (h·m 2 bar).

Embodiment 2

[0073] The amount of active substance in the synthesis

[0074] MXene@Fe 2 o 3 Actual MXene content in hybrid nanoparticles: 2.20mg

[0075] MXene@Fe 2 o 3 Actual Fe in hybrid nanoparticles 2 o 3 Content: 63.36mg

[0076] Volume of surface covering cellulose dispersion: 1.5mL

[0077] Hg removal 2+ See Table 2 for wastewater conditions.

[0078] Table 2 Reaction Conditions

[0079] condition scope Film area 12.56cm 2

[0080] Under the above conditions to remove Hg 2+ Wastewater treatment can achieve 97% efficiency, and the flux is 16~17L / (h·m 2 bar).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com