Preparation method of modified zeolite adsorption material for water purification equipment

A technology for modifying zeolite and adsorption materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of small adsorption capacity and frequent regeneration of natural zeolite, and achieve excellent adsorption performance and adsorption capacity. The effect of not decreasing and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

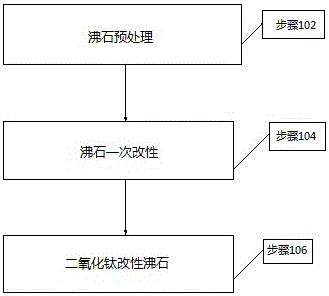

[0026] figure 1 A flowchart showing a method for preparing a modified zeolite adsorption material for water purification equipment according to a method embodiment of the present invention includes the following steps:

[0027] Step S102, zeolite pretreatment: pulverize the zeolite ore, screen it with an 18-mesh sieve, select zeolite with a specific particle size range, remove the powder with fine particle size and large particle size zeolite, then rinse it with pure water, air dry it naturally or place it in the heating and drying in an oven to obtain the first pretreated zeolite, and placing it in a drying device for subsequent use;

[0028] Step S104, primary modification of zeolite: prepare sodium chloride solution with pure water, then soak the first pretreated zeolite in the sodium chloride solution, heat and stir, take out the first pretreated zeolite after completion, and rinse with pure water clean, then put it into an oven for heating and drying to obtain the second...

Embodiment 1

[0045] 1. Zeolite pretreatment:

[0046] The zeolite ore is crushed, screened with an 18-mesh screen, and the zeolite with a particle size of 1-20 mm is selected, and the fine powder and large-grained zeolite are removed. Then rinse it with pure water, place it in a desiccator to dry naturally for 26 hours, and set it aside.

[0047] 2. Primary modification of zeolite:

[0048] Prepare 4.6mg / L sodium chloride solution with purified water. Then soak the zeolite in sodium chloride solution and heat to 95°C while stirring for 120 minutes. When finished, take it out and rinse it with pure water.

[0049] Then put it into an oven and heat it to 100° C. and dry it for 15 minutes, and place it in a drying appliance for later use.

[0050] 3. Titanium dioxide modified zeolite:

[0051] Place the preliminarily modified zeolite in the nano-titanium dioxide solution for soaking, then take it out and spin dry. Use a wire mesh screen to place in an oven heated to 100 and dry for 10 min...

Embodiment 2

[0054] 1. Zeolite pretreatment:

[0055] The zeolite ore is crushed, screened with an 18-mesh screen, and the zeolite with a particle size of 1-20 mm is selected, and the fine powder and large-grained zeolite are removed. Rinse it with pure water, place it in an oven and heat it to 50°C for 10 minutes, take it out and place it in a dry ceramic jar for later use.

[0056] 2. Primary modification of zeolite:

[0057] Prepare 5mg / L sodium chloride solution with purified water. Then soak the zeolite in sodium chloride solution and heat to 98°C while stirring for 120 minutes. When finished, take it out and rinse it with pure water.

[0058] Then put it into an oven and heat it to 100°C to dry for 10 minutes, and place it in a drying appliance for later use.

[0059] 3. Titanium dioxide modified zeolite:

[0060] Place the preliminarily modified zeolite in the nano-titanium dioxide solution for soaking, then take it out and spin dry. Use a wire mesh screen to place in an oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com