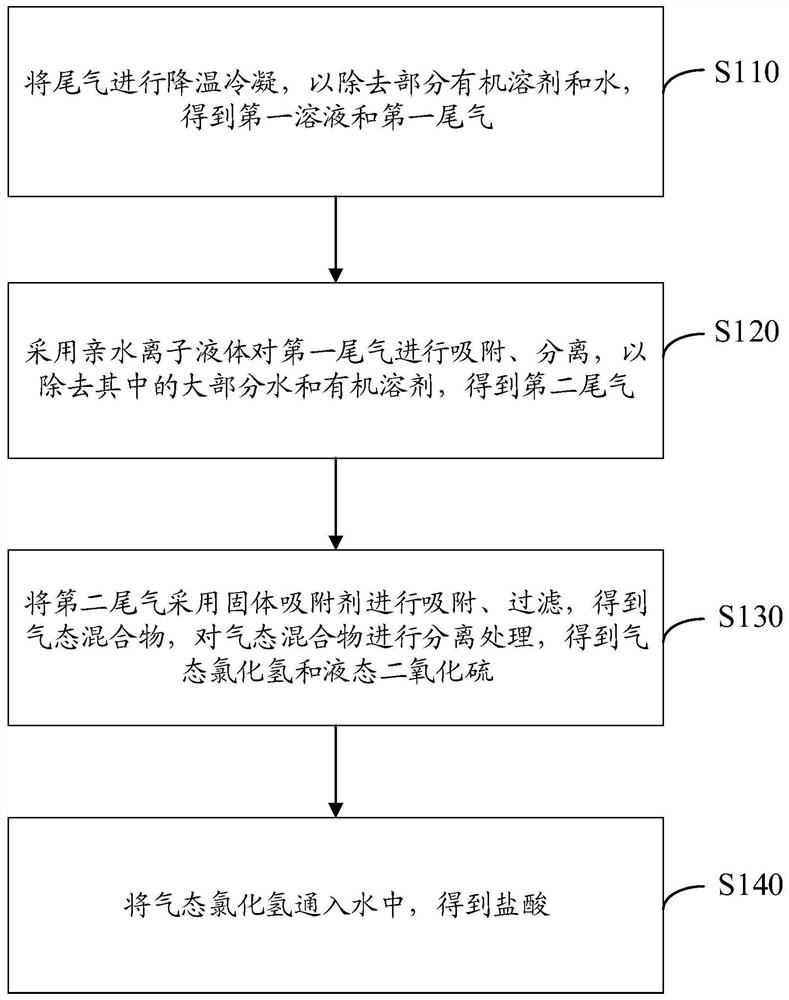

Tail gas treatment method

A tail gas treatment and tail gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor separation effect, difficult post-treatment, equipment corrosion, etc., and achieve low cost, high reproducibility, high treatment simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

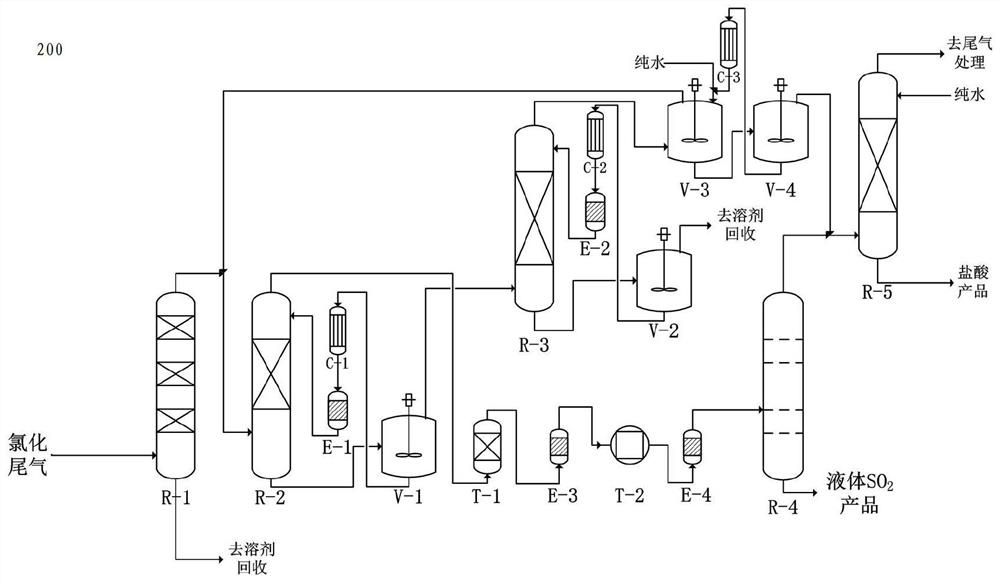

Embodiment 1

[0094] R-1 chloride tail gas cooling and condensing the cooling tower, the condensate to 0 deg.] C, after condensation, the cooling tower bottom solution R-1 is sent to solvent recovery, cooling tower overhead exhaust R-1, i.e., the exhaust gas enters the first dehydration R-2 column desolvation process continues. First off-gas entering the pre-dehydration hydrophilic ionic liquid solvent removal column R-2, the adsorption temperature is 40 ℃, wherein the hydrophilic ionic liquid as pyridine bisulfate 50wt% and 50wt% methyl imidazole bisulfate mixture. Desolvation dehydration column top product R-2 via the second exhaust gas canister T-1 adsorb residual organic gas, then through a filter E-3, the compressor T-2, E-4 after the filter process proceeds plus pressure rectification column R-4, the pressing pressure of the rectification column 2MPa, column bottom temperature of 0 ℃, column top temperature of 10 ℃, to obtain high purity liquid SO pressure rectification column from the bo...

Embodiment 2

[0097] The chlorinated tail gas is cooled and condensed by cooling tower R-1, condensed to 30 ° C, condensing, cooling tower R-1 tower bottom aqueous solution, cooling tower R-1 tail gas, i.e., first exhaust gas into dehydration The degradation tower R-2 continues to be treated. The first exhaust gas enters the preset dehydrated dehydrocolysis pirate R-2, the adsorption temperature is 30 ° C, wherein the hydrophilic ionic liquid is 40 wt% pyridine sulfate and 60 wt% ethylimidazole sulfate. mixture. The hydrophilic ionic liquid after the dehydrated degrading tower R-2 is used to enter the ionic liquid regeneration kettle V-1 for regeneration treatment, and the regeneration temperature is 100 ° C, the vacuum degree -0.07 MPa, and the hydrophilic ion liquid after regeneration is regenerated. The bottom of the kettle V-1 is produced, and after cooling by the condenser E-1 to 30 ° C, and after filtration of the filter E-1, the dehydrated dehydrating tether R-2 continues to use. The sec...

Embodiment 3

[0100] The tail gas is cooled by the cooling tower R-1, condensed to 10 ° C, condensate, the cooling tower R-1 bottom aqueous solution is sent to the solvent recovery, the tower of the tower of the tower R-1, that is, the first exhaust gas into the dehydration The degradation tower R-2 continues to be treated. The first exhaust gas enters the preset dehydrated dehydricate R-2, the adsorption temperature is 40 ° C, wherein the hydrophilic ionic liquid is 20 wt% pyridine sulfate, 30 wt% methylimidazole sulfate and hydrogenate. Mixtures of 50 wt% ethylimidazole sulphate sulphate. The hydrophilic ionic liquid after the dehydrated release tower R-2 is used to enter the ionic liquid regeneration kettle V-1 for regeneration treatment, the regeneration temperature is 120 ° C, the vacuum-0.05 MPa, the hydrophilic ion liquid after regeneration is regenerated The bottom of the kettle V-1 is produced, and after cooling from the condenser E-1 to 20 ° C, and after filtration of the filter E-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com