Improved method for recovering methanol from methanol rectification purge gas

A technology for recovering methanol and methanol rectification, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems such as inability to meet, and achieve improved structure, reduced circulation, and flexible washing operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

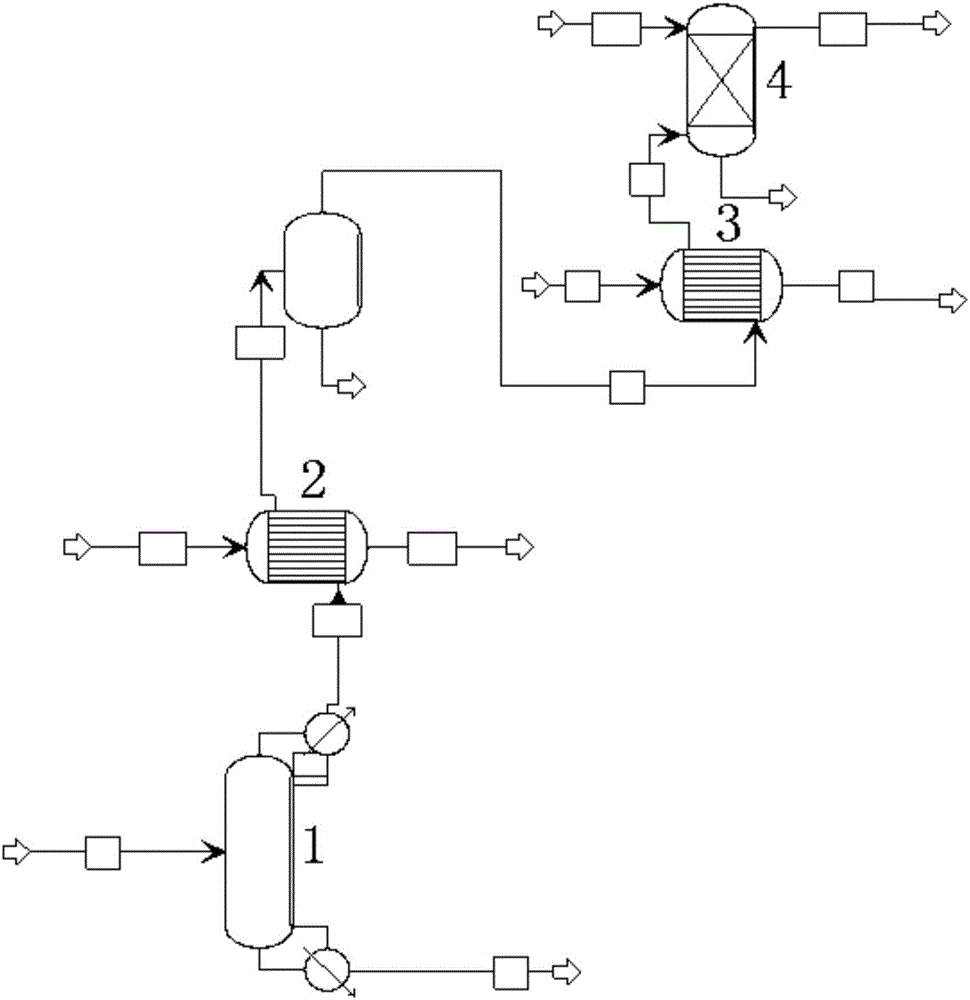

[0038] Such as figure 1 , first preheat the crude methanol from the methanol synthesis section to about 72°C and then inject it into the pre-rectification tower. The purpose is: to provide the pre-distillation tower with heat for distilling crude methanol and to adjust the pressure and temperature of the pre-rectification tower, then input the crude methanol until the liquid level is about 50-90%, and then use steam to heat the evaporator To about 50 ~ 100 ℃, at this time the pressure is about 1 bar. The pressure, temperature and liquid level of the evaporator are automatically adjusted by the remote DCS system. In addition, the pre-distillation column is equipped with: safety relief device (PSV), liquid level and pressure interlock system (interlock) and emergency discharge system (ESD). Start the steam reboiler, when the process parameters reach the set value, the two-stage condenser at the top of the pre-distillation tower starts to condense and separate, and about 5-10% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com