Flexible electrochemical glucose sensor and preparation method thereof

A glucose sensor and electrochemical technology, applied in the field of sensors, can solve the problems of low sensor monitoring efficiency, dense coating, poor adhesion, etc., and achieve the effects of broadening the detection range, enhancing contact, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A method for preparing a flexible electrochemical glucose sensor, comprising the following steps:

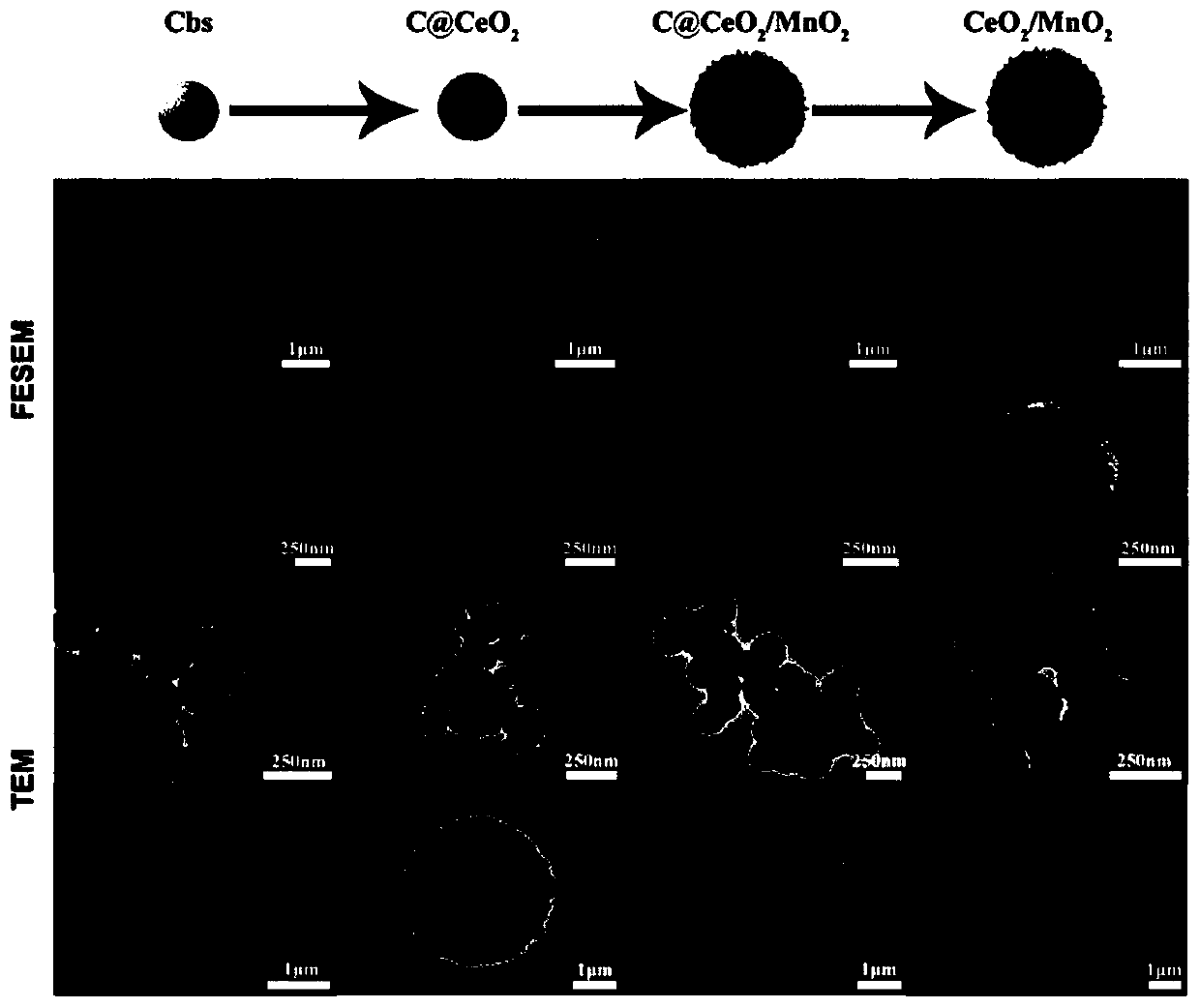

[0072] Carbon spheres (Cbs) were prepared by reacting 0.56 mM / mL glucose aqueous solution in a Teflon-lined stainless steel autoclave at 180 °C for 12 h;

[0073] Disperse 0.1 g of Cbs in 15 mL of ethanol, and after ultrasonication for 1 h, add 25 mL of Ce(NO 3 ) 3 ·6H 2 The aqueous solution of O (12mM) and polyvinylpyrrolidone (PVP, 3.6mg / mL) was stirred at room temperature for 2h and reacted at 75°C for 4h to prepare C@CeO 2 nanospheres;

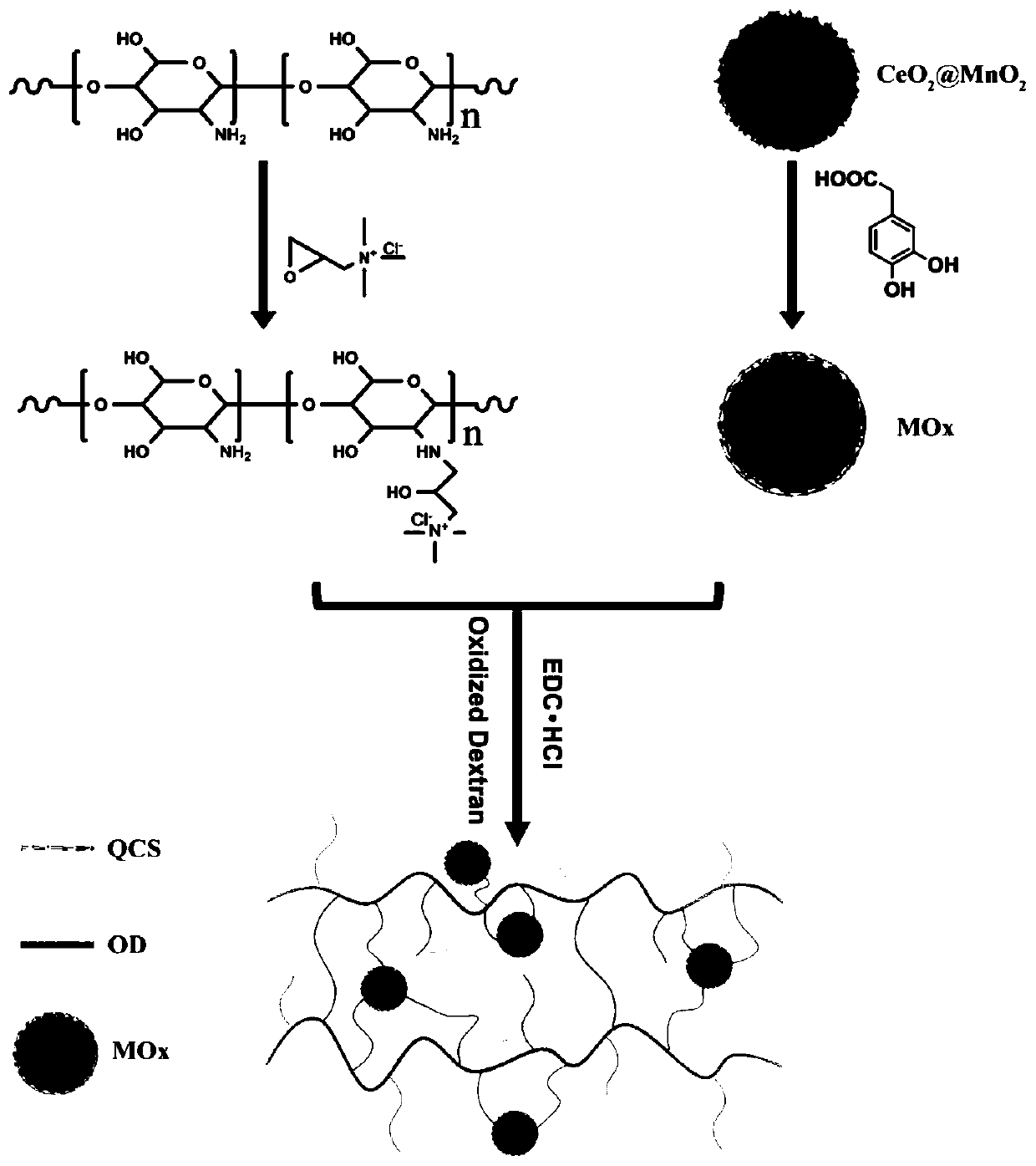

[0074] 0.1g of C@CeO 2 Add 25 mL of KMnO to the nanospheres 4 (32mM) solution, ultrasonically dispersed for 30min, and then reacted at 80°C for 4h. After cooling to room temperature, the nanospheres were separated by suction filtration, washed with ethanol and deionized water, dried at 60 °C for 1 h, and then annealed in air at 275 °C for 2 h to prepare CeO 2 / MnO 2 Hollow nanospheres (such as figure 1 shown);

[0075] 12mL ...

Embodiment 2

[0084] A method for preparing a flexible electrochemical glucose sensor, comprising the following steps:

[0085] Carbon spheres (Cbs) were prepared by reacting 0.56 mM / mL glucose aqueous solution in a Teflon-lined stainless steel autoclave at 180 °C for 12 h;

[0086] Disperse 0.1 g of Cbs in 15 mL of ethanol, and after ultrasonication for 1 h, add 25 mL of Ce(NO 3 ) 3 ·6H 2 The aqueous solution of O (12mM) and polyvinylpyrrolidone (PVP, 3.6mg / mL) was stirred at room temperature for 2h and reacted at 75°C for 4h to prepare C@CeO 2 nanospheres;

[0087] 0.1g of C@CeO 2 Add 25 mL of KMnO to the nanospheres 4 (32mM) solution, ultrasonically dispersed for 30min, and then reacted at 80°C for 4h. After cooling to room temperature, the nanospheres were separated by suction filtration, washed with ethanol and deionized water, dried at 60 °C for 1 h, and then annealed in air at 275 °C for 2 h to prepare CeO 2 / MnO 2 Hollow nanospheres (such as figure 1 shown);

[0088] 12mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com