Aqueous capsule for cigarette and preparation method of aqueous capsule

A technology of water capsules and capsules, which is applied in the fields of tobacco, application, and treatment of tobacco, and can solve the problems of failing to keep the smoke moist and the moisture content of the capsules dropping sharply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

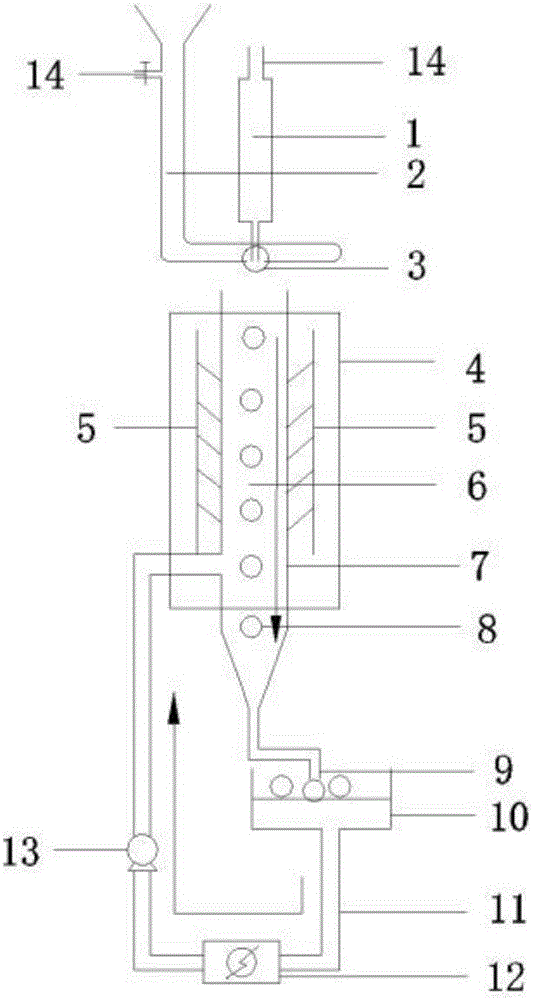

Image

Examples

Embodiment 1

[0081] Embodiment 1: the preparation method of capsule with water for tobacco

[0082] The implementation steps of this embodiment are as follows:

[0083] A. Preparation of water-soluble core fluid

[0084] Dissolve the anisyl alcohol water-soluble substance in pure water according to the weight ratio of pure water to water-soluble substance 1:0.10 to obtain the water-soluble core liquid; the density of the water-soluble core liquid is measured by the method described in this manual. 1.0g / cm 3 .

[0085] B. Preparation of capsule wall material liquid

[0086] Mix 24 parts by weight of bisphenol A epoxy acrylic resin, 10 parts by weight of pinene resin and 1.0 part by weight of 2-hydroxy-2-methyl-1-phenyl-ketone compound, then heat and stir at a temperature of 50°C Fully dissolve, store away from light, and then let stand for more than 2 hours, cool and remove air bubbles to obtain the capsule wall material liquid;

[0087] C. Protection solution preparation

[0088] Mix...

Embodiment 2

[0091] Embodiment 2: the preparation method of water capsule for tobacco

[0092] The implementation steps of this embodiment are as follows:

[0093] A. Preparation of water-soluble core fluid

[0094] Dissolve the cis-jasmone water-soluble substance in pure water according to the weight ratio of pure water to water-soluble substance 1:2.0 to obtain the water-soluble core liquid; the density of the water-soluble core liquid is measured by the method described in this manual. is 0.9g / cm 3 .

[0095] B. Preparation of capsule wall material liquid

[0096] Mix 36 parts by weight of bisphenol A epoxy acrylic resin, 20 parts by weight of other resins of novolac epoxy acrylic resin and 5.0 parts by weight of 1-hydroxycyclohexyl phenyl ketone compound, then heat at a temperature of 60°C and stir to fully dissolve , kept away from light, then left to stand for more than 2h, cooled and removed air bubbles, to obtain the capsule wall material liquid;

[0097] C. Protection solutio...

Embodiment 3

[0101] Embodiment 3: the preparation method of water capsule for tobacco

[0102] The implementation steps of this embodiment are as follows:

[0103] A. Preparation of water-soluble core fluid

[0104] According to the weight ratio of pure water and water-soluble substance 1:0.01, the maltol water-soluble substance is dissolved in pure water to obtain the water-soluble core liquid; measured by the method described in this manual, the density of the water-soluble core liquid is 1.3 g / cm 3 .

[0105] B. Preparation of capsule wall material liquid

[0106] 10 parts by weight of bisphenol A epoxy acrylic resin, 46 parts by weight of epoxidized oil acrylate other resins and 1.8 parts by weight of 2-hydroxyl-2-methyl-1-phenyl-ketone compound are mixed uniformly, and then heated at a temperature of 55 Heating at ℃, stirring to fully dissolve, storing in the dark, then standing for more than 2 hours, cooling and removing air bubbles to obtain the capsule wall material liquid;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com