Comprehensive treatment process for high-temperature removed dust

A technology for high-temperature dust removal and comprehensive treatment, which is applied in the field of flue gas treatment in the metallurgical industry, can solve the problems of high-temperature dust removal ash having no energy-saving effect, and achieve the effects of reducing energy consumption, increasing comprehensive benefits, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

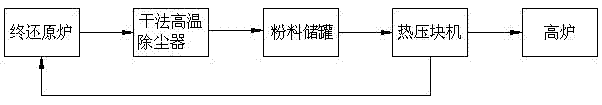

[0024] In this embodiment, the high-temperature dust removal comprehensive treatment process of the present invention is used to process the high-temperature flue gas generated by the final reduction furnace in the two-step smelting reduction process, including the following steps:

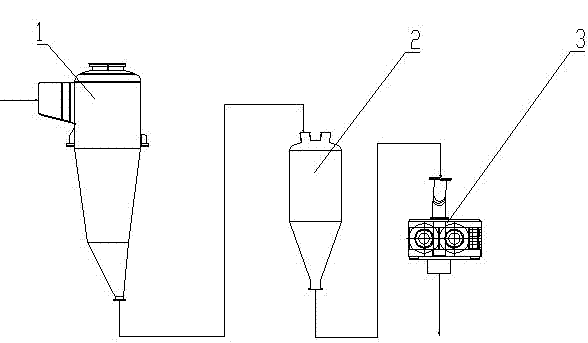

[0025] a) Dedust the high-temperature flue gas produced by the final reduction furnace in the two-step smelting reduction process, and use the dry high-temperature dust collector 1 to obtain high-temperature dedusting ash, which is stored in the dust storage tank 2. The temperature of the high-temperature dedusting ash can reach 700-850°C, the clean high-temperature gas after dedusting is mainly used in the pre-reduction shaft furnace, and the dry-process high-temperature dust collector adopts a hot cyclone dust collector. Of course, the purpose of the present invention can also be achieved by using other dry-process high-temperature dust collectors;

[0026] b) Without cooling treatment, use the h...

Embodiment 2

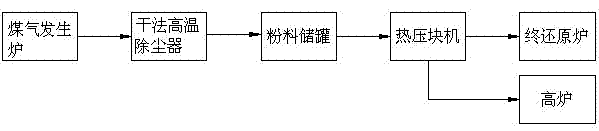

[0030] In this embodiment, the high-temperature dust-removing ash comprehensive treatment process of the present invention is used to process the high-temperature flue gas produced by the coal gasifier in the coal gasification process, including the following steps:

[0031] a) Dedust the high-temperature flue gas produced by the gas generator, and use the dry-process high-temperature dust collector 1 to obtain high-temperature dedusting ash, which is stored in the dust storage tank 2. The temperature of the high-temperature dedusting ash can reach 700-850 ° C. After dedusting The clean high-temperature gas is used in the pre-reduction shaft furnace or other chemical units, and the dry high-temperature dust collector adopts a hot cyclone dust collector;

[0032] b) Without cooling treatment, use the hot briquetting machine 3 to press the high-temperature dedusting ash obtained in step a) into a hot dedusting ash briquette;

[0033] c) Since the hot dedusting ash briquette main...

Embodiment 3

[0036] In this embodiment, the high temperature flue gas generated by the converter is processed by using the high temperature comprehensive dust removal process of the present invention, including the following steps:

[0037] a) Dedusting the high-temperature flue gas discharged from the converter steelmaking vaporization hood, the temperature of the high-temperature flue gas reaches 800-1000°C, and the dust concentration reaches 200g / Nm 3 , the high-temperature dedusting ash obtained after dedusting by the dry-process high-temperature deduster 1 is stored in the dust storage tank 2, the temperature of the high-temperature dedusting ash can reach 750-950°C, and the clean high-temperature flue gas of dedusting enters the waste heat recovery device;

[0038] b) Without cooling treatment, use the hot briquetting machine 3 to press the high-temperature dedusting ash obtained in step a) into a hot dedusting ash briquette;

[0039] c) Since the hot dedusting ash briquette in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com