Waste gas recovery processing system and recovery processing technique used in chemical car loading

A waste gas recovery and treatment system technology, applied in the direction of steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of air pollution in storage areas and storage areas, hidden dangers of environmental pollution, large volatilization of chemicals, etc., and achieve realization Circular recovery treatment, remarkable energy saving and environmental protection effect, and enhanced energy saving and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

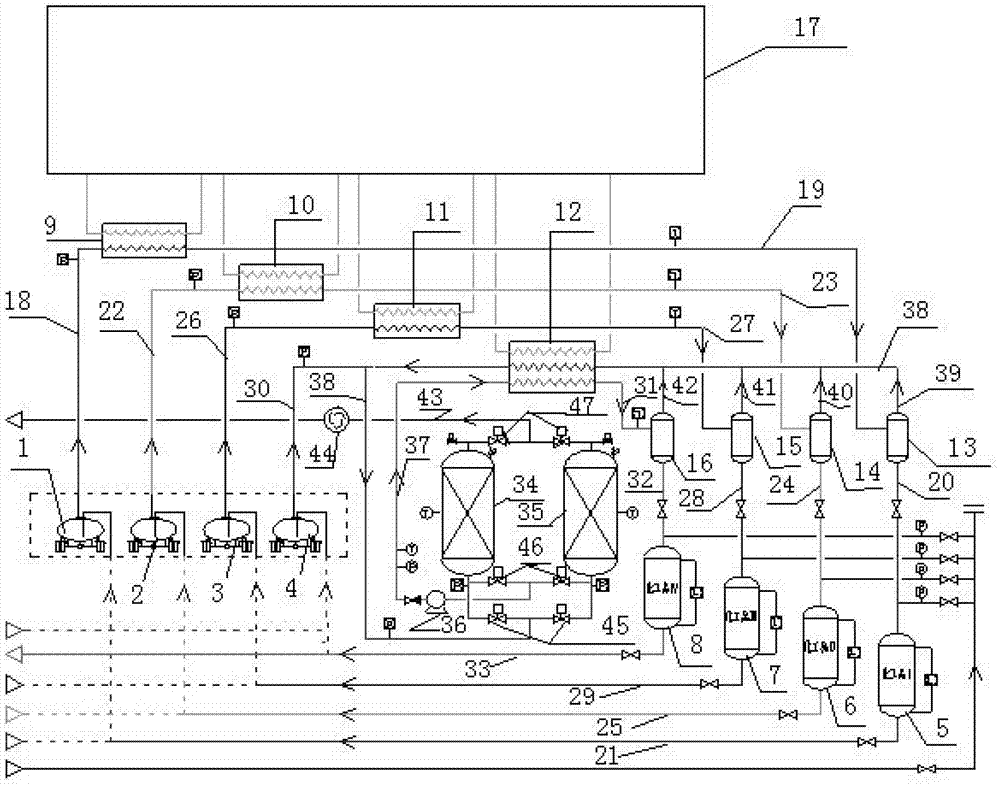

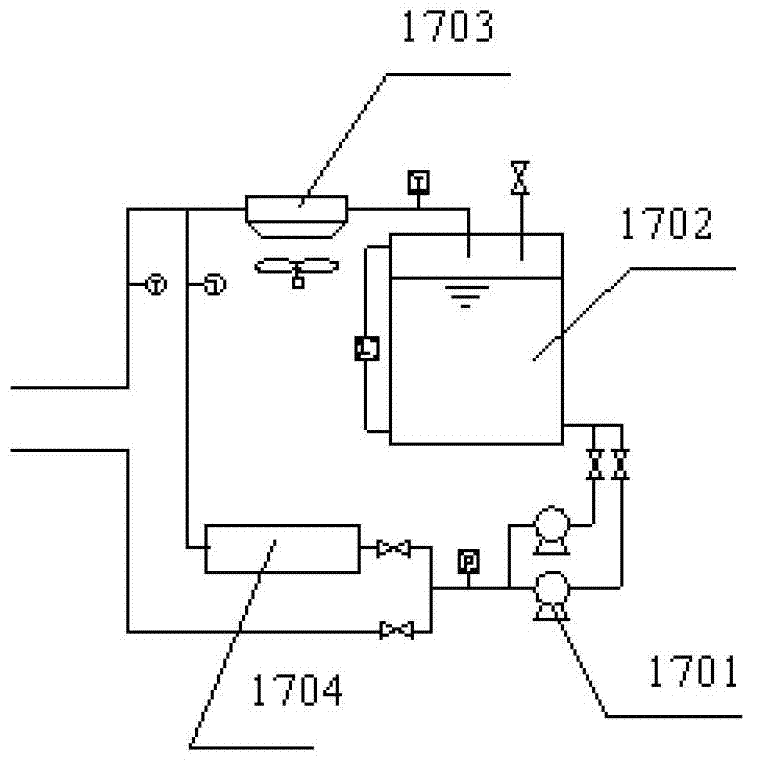

[0042] Such as figure 1 As shown, the present invention is used for waste gas recovery treatment system when loading chemicals, including storage tanks, tank cars, pipelines for transporting chemicals from storage tanks to tank cars, tail gas discharge devices, interconnected condensation separation devices and adsorption separation device, the condensation separation device includes an interconnected refrigerating unit 17, a condenser, and a gas-liquid separator, and the adsorption separation device includes an interconnected adsorption device and a desorption device, and the adsorption device is connected to the gas-liquid separator , the desorption device is connected to the condenser, wherein:

[0043] There are four tank cars, which are respectively the first chemical tank car 1, the second chemical product tank car 2, the third chemical product tank car 3, and the mixed product tank car 4;

[0044] There are four storage tanks, namely the first chemical storage tank 5, ...

Embodiment 2

[0085] Such as figure 1 As shown, the setting and distribution of an exhaust gas recovery treatment system used for loading chemicals into vehicles are the same as those in Embodiment 1.

[0086] Apply the waste gas recovery and treatment system of the present invention to the waste gas recovery and treatment of a chemical product when it is loaded into the vehicle. Taking the chemical product benzene as an example, in the waste gas recovery and treatment system, the mixed product tank The tank car 4 is a benzene tank truck, the mixed product storage tank 8 is a benzene storage tank, the mixed gas condenser 12 is a gaseous benzene condenser, the mixed gas-liquid separator 16 is a benzene gas-liquid separator, and the mixed waste gas transportation pipeline 30 is used for benzene waste gas transportation Pipeline, mixed condensate product delivery pipeline 31 is benzene condensate product delivery pipeline, mixed condensate separation liquid product delivery pipeline 32 is benz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com