Calcium-zinc compound stabilizer as well as preparation method and application thereof

A calcium-zinc composite and stabilizer technology, applied in the field of chemical stabilizers, to achieve the effects of no three wastes, reduced production costs, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

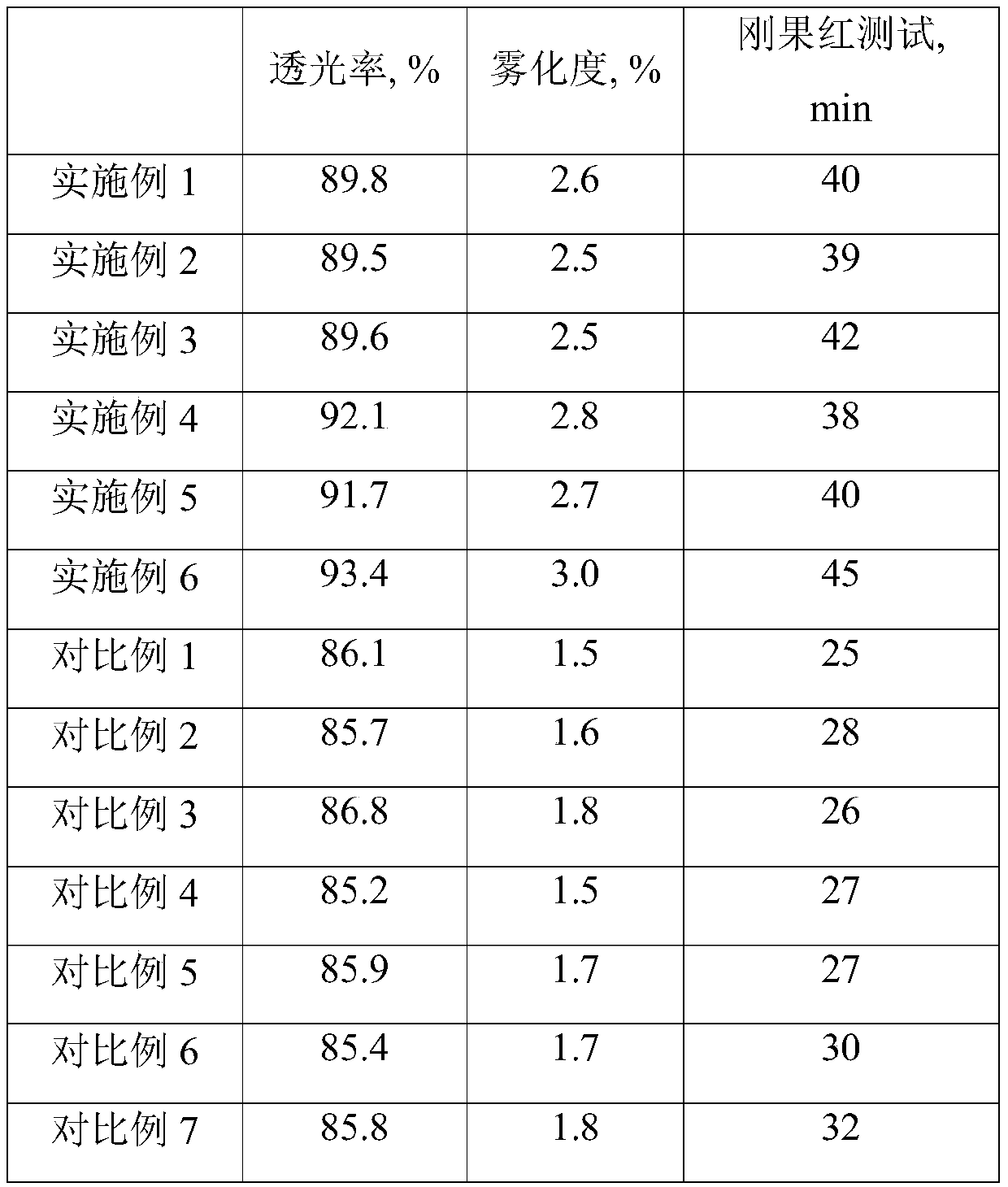

Examples

Embodiment 1

[0061] This embodiment provides a calcium-zinc composite stabilizer, which is composed of the following raw materials in mass percentage: isooctanoic acid: 10%, benzoic acid: 10%, ultrafine zinc oxide: 4.2%, ultrafine calcium oxide: 6.5%, non-toxic Phosphite: 8%, DINCH: 35%, ATBC: 1%, TXIB: 0.3%, methyl chloride: 25%; the average particle size of ultrafine zinc oxide is 30nm; the average particle size of ultrafine calcium oxide is 40nm, non-toxic phosphite is 4,4-diisoylidene bisphenol (12-14) carbon alkyl ester of phosphite;

[0062] The preparation method of above-mentioned calcium-zinc composite stabilizer specifically comprises the following steps:

[0063] S1. Carry out dehydration and salification treatment of isooctanoic acid, benzoic acid, zinc oxide and calcium oxide in the above ratio, and obtain calcium salt and zinc salt respectively; wherein, the process parameters of dehydration and salification treatment are: the reaction temperature is 100°C, The reaction time...

Embodiment 2

[0066] This embodiment provides a calcium-zinc composite stabilizer, the main difference from Example 1 is that it consists of the following raw materials in mass percentage: isooctanoic acid: 30%, benzoic acid: 2%, ultrafine zinc oxide: 0.5%, ultrafine Fine calcium oxide: 1.2%, non-toxic phosphite: 15%, DINCH: 20%, ATBC: 5%, TXIB: 3%, chloromethyl ester: 23.3%; the average particle size of ultrafine zinc oxide is 80nm; The average particle size of superfine calcium oxide is 80nm;

[0067] The preparation method of the above-mentioned calcium-zinc composite stabilizer refers to the operation steps of Example 1, the main difference is that in step S1, the process parameters of the dehydration and salt-forming treatment are as follows: the reaction temperature is 120° C., and the reaction time is 15 minutes.

Embodiment 3

[0069] This embodiment provides a calcium-zinc composite stabilizer, the main difference from Example 1 is that it consists of the following raw materials in mass percentage: isooctanoic acid: 22%, benzoic acid: 4%, ultrafine zinc oxide: 3%, ultrafine Fine calcium oxide: 1.9%, non-toxic phosphite: 10%, DINCH: 25%, ATBC: 2%, TXIB: 0.1%, chloromethyl ester: 32%; the average particle size of ultrafine zinc oxide is 50nm; The average particle size of superfine calcium oxide is 50nm;

[0070] The preparation method of the above-mentioned calcium-zinc composite stabilizer refers to the operation steps of Example 1, the main difference is that in step S1, the process parameters of the dehydration and salt-forming treatment are as follows: the reaction temperature is 110° C., and the reaction time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com