Flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and preparation method of flame retardant

An epoxy resin and epoxy resin curing technology, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as excessive smoke, achieve good compatibility, improve Flame retardant performance, easy post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

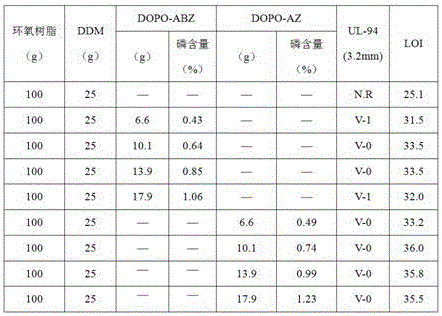

Examples

Embodiment 1

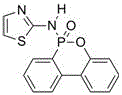

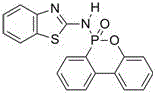

[0026] 11.9 g DOPO, 8.3 g 2-aminobenzothiazole, 7.6 ml triethylamine, and 100 ml methylene chloride were added to a reactor with a temperature control device and a stirring device, and an inert gas was introduced, under stirring and ice bath conditions Add 5.3 ml of carbon tetrachloride dropwise, and control the temperature not higher than 15°C, and return to room temperature for reaction after the dropwise addition is completed. After the reaction is completed, the reaction mixture is suction-filtered first, and the filtrate is suspended and evaporated to obtain a viscous liquid. Finally, the viscous liquid is washed with water and acetone for 3 to 4 times, and vacuum-dried to obtain the product DOPO-ABZ, with a yield of 82%. .

Embodiment 2

[0028] Add 11.9 g DOPO, 8.3 g 2-aminobenzothiazole, 15.2 ml triethylamine, and 30 ml acetone into a reactor with a temperature control device and a stirring device, feed inert gas, and drop Add 5.3 ml of carbon tetrachloride, and control the temperature not higher than 15 ° C, return to room temperature after the dropwise addition is complete. After the reaction was completed, it was filtered with suction, washed with water, and dried in vacuum to obtain the product DOPO-ABZ with a yield of 86%.

Embodiment 3

[0030] Add 11.9 g DOPO, 9.9 g 2-aminobenzothiazole, 8.4 ml triethylamine, and 150 ml acetone into a reactor with a temperature control device and a stirring device, feed inert gas, and drip under stirring and ice-bath conditions Add 10.6 ml of carbon tetrachloride, and control the temperature not higher than 15 ° C, return to room temperature after the dropwise addition is complete. After the reaction was completed, it was filtered with suction, washed with water, and dried in vacuum to obtain the product DOPO-ABZ with a yield of 86%.

[0031] The test and analysis results of flame retardant DOPO-ABZ are as follows:

[0032] 1 H NMR (400 MHz, DMSO-d 6 ), δ (ppm): 12.73 (s, N-H), 8.15-8.19 (m, 2H), 7.84 (dd, J=14Hz, 7.2 Hz, 1H), 7.71-7.77 (m, 2H), 7.56 (td, J=7.6 Hz, 3.2 Hz, 1H), 7.44 (t, J=7.6 Hz, 1H), 7.26-7.33 (m, 3H), 7.14-7.21 (m, 2H);

[0033] 31 P NMR (400 MHz, DMSO-d 6 ), δ (ppm): 12.00;

[0034] FTIR (KBr, cm -1 ), 3439.8 (N-H), 3064.6 (Ar-H), 1468.3 (P-Ph), 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com