Stress sensor with self-repairing ability and preparation method thereof

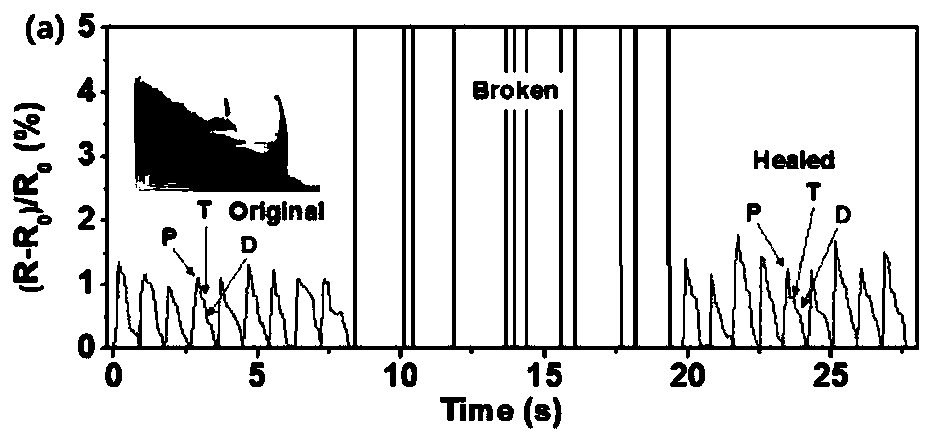

A stress sensor and self-repairing technology, applied in the direction of nanotechnology for sensing, measurement of the force of properties of piezoelectric resistance materials, nanotechnology for materials and surface science, etc., can solve the problem that stress sensors have not seen before Reporting, poor sensitivity and other issues, to achieve the effect of easy batch preparation, high sensitivity, and good anti-fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Weigh 0.2 g of graphene oxide with a sheet size of about 1-2 μm prepared by a chemical method and place it in a beaker, add 100 mL of deionized water, and ultrasonicate for 30 minutes to obtain a 2 mg / mL graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0042] (2) Weigh 1g of low molecular weight polyvinyl alcohol and place it in a beaker, add 99mL of deionized water, heat and stir at 80°C to dissolve, and obtain a 1% mass fraction of polyvinyl alcohol solution

[0043] (3) Weigh 10mg of calcium chloride into a beaker, add 9.99mL of deionized water, and ultrasonicate for 10 minutes to obtain a 1mg / mL calcium chloride solution

[0044] (4) Weigh 2mL of silver nanowire (length 5um, diameter 30-40nm) dispersion (10mg / mL) in the reagent bottle, add 1.25mL of the graphene oxide solution obtained in step (1), and ultrasonically vibrate to make it re- dispersion. Suction filtration with a microporous membra...

Embodiment 2

[0050] (1) Weigh 0.2 g of MXene (Ti 3 C 2 X) Place in a beaker, add 100mL of deionized water, and sonicate for 30 minutes to obtain 2mg / mL of MXene(Ti 3 C 2 X) Dispersions.

[0051] (2) Weigh 0.4mL silver nanowire (length 5um, diameter 30-40nm) dispersion (10mg / mL) in the reagent bottle, add 0.4mL step (1) to obtain MXene (Ti 3 C 2 X) solution, sonicated to redisperse it. Suction filter with microporous membrane, wash several times with deionized water, suck off the supernatant, and obtain MXene containing silver nanowires (Ti 3 C 2 X) Conductive gel.

[0052] (3) Weigh 1 g of polyacrylic acid and place it in a beaker, add 99 mL of deionized water, heat at 80° C. and stir to dissolve to obtain a 1% mass fraction of polyacrylic acid solution.

[0053] (4) Weigh 10 mg of ferric chloride into a beaker, add 10 mL of deionized water, and sonicate for 10 minutes to obtain a 1 mg / mL ferric chloride solution.

[0054] (5) Take 8 μL of the polyacrylic acid solution obtained in...

Embodiment 3

[0058] (1) Weigh 0.2 g of graphene oxide with a sheet size of about 1-2 μm prepared by a chemical method and place it in a beaker, add 100 mL of deionized water, and ultrasonicate for 30 minutes to obtain a 2 mg / mL graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0059] (2) Weigh 1.35g of adamantyl tetraethylene glycol ether and 5g of β-cyclodextrin tetraethylene glycol ether into a beaker, add 56.15mL of deionized water, and stir for 24 hours to obtain 10% host-guest-containing Clear transparent dispersion of the structure.

[0060] (3) Weigh 6mL of silver nanowire (length 5um, diameter 30-40nm) dispersion (10mg / mL) into a reagent bottle, add 10mL of graphene oxide solution obtained in step (1), and ultrasonically oscillate to redisperse it . Suction filtration with a microporous membrane, washing with deionized water several times, and sucking off the supernatant to obtain a conductive gel containing silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com